Automatic forging centering device

An automatic centering and forging technology, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc., can solve problems such as high labor intensity, low production efficiency, and hidden safety hazards, and achieve production High efficiency, high processing precision, easy to promote the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

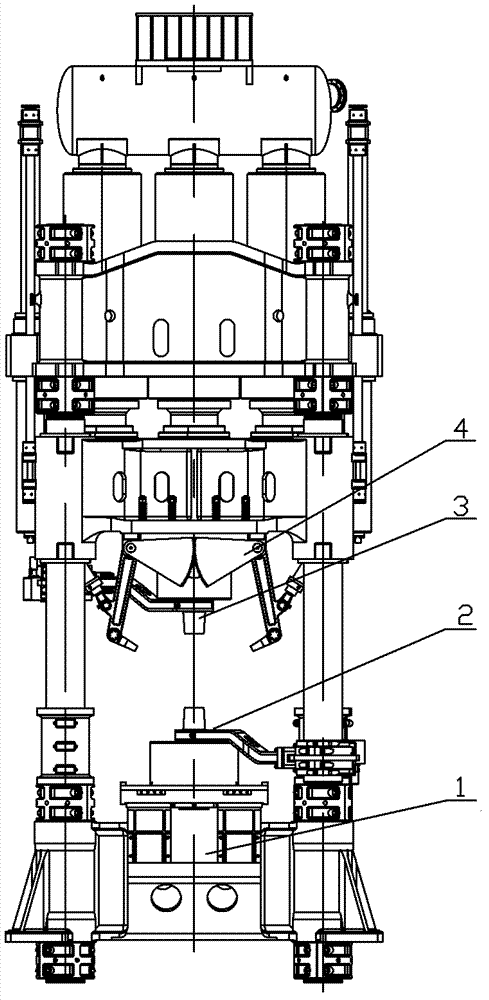

[0018] refer to Figure 1-Figure 8 , Forging automatic centering device, the device is installed on the hydraulic host 1. The above-mentioned device is mainly composed of three parts: an upper punching assembly, a lower punching assembly and a centering assembly.

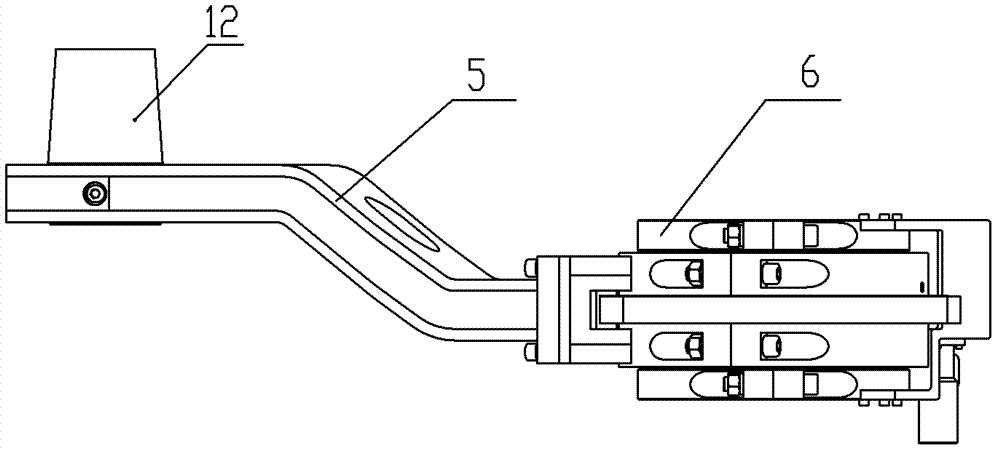

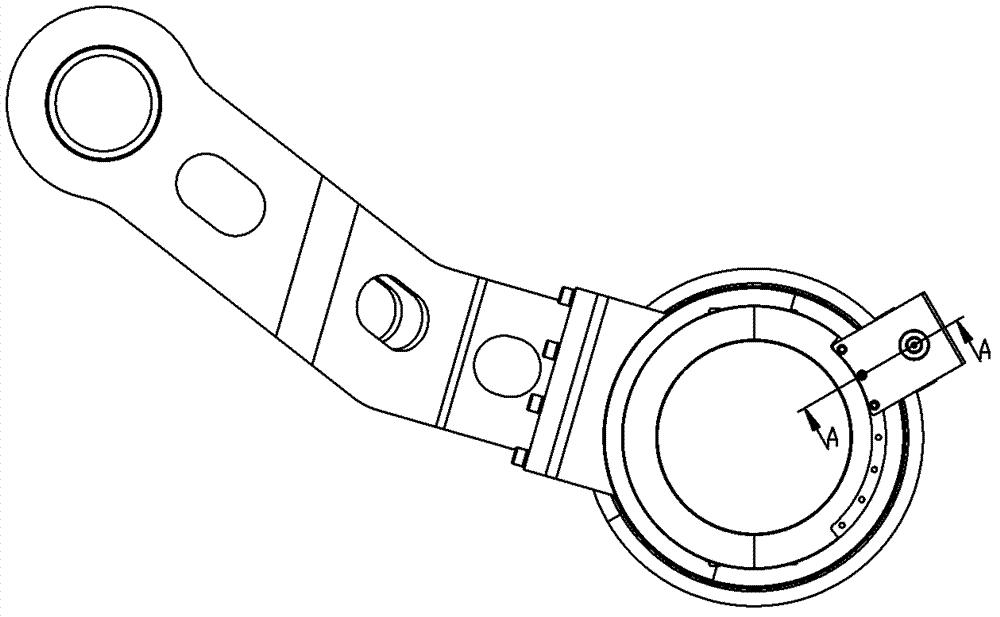

[0019] The upper punching assembly includes an upper punch 21, an upper rotating arm 20, an upper guide sleeve 19, a motor frame A18, a motor A17, a rotating gear A16, a pinion A15, a rotating sleeve A14 and a sliding sleeve 13. One end of the upper rotating arm 20 is fixed with an upper punch 21 ; the other end is connected with the upper guide sleeve 19 through the rotating shaft sleeve A14 , wherein the upper guide sleeve 19 is connected to the moving beam of the main engine 1 with bolts. A motor frame A18 is fixed on the above-mentioned upper guide sleeve 19, and a motor A17 is installed on the motor frame A18. The pinion gear A15 on the output shaft of the motor A17 meshes with the rotating gear A16, and drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com