Six-station radial tyre steel wire ring production line

A radial tire and bead traveler technology, which is applied in tire, wire processing, and ring manufacturing by wire, etc., can solve the problems of low winding efficiency, low space utilization, and low production line efficiency, so as to improve production efficiency, improve utilization rate, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

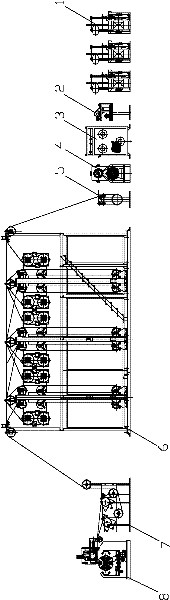

[0036] Such as figure 1 , 2 As shown, the present invention provides a six-station radial tire bead production line, including a steel wire guide device 1, a steel wire decontamination device 2, a steel wire electric heating device 3, an extruder 4, and a flared guide wire arranged in sequence at a distance Device 5, storage device 6, and bending device 7 and winding machine 8.

[0037] The steel wires are first guided by the guide device 1, and the six steel wires enter the decontamination device 2 to remove surface dirt and rust, and then are electrically heated and enter the extruder for scraping. The six steel wires exported in the extruder have a small spacing, and the flaring wire guide device 5 can expand the spacing to an appropria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com