One-shot forming mould of Y-type tee

A technology for forming molds and molds, applied in the direction of metal extrusion molds, etc., can solve the problems of long manufacturing cycle, waste of human resources and costs, difficult quality control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

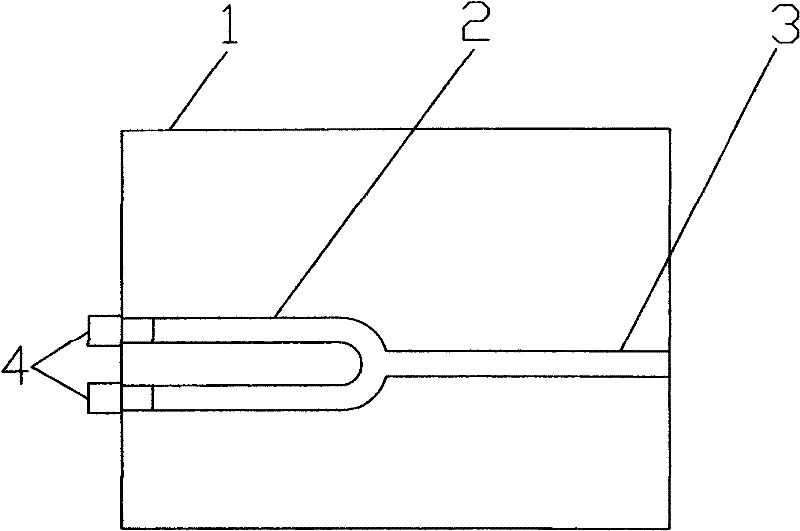

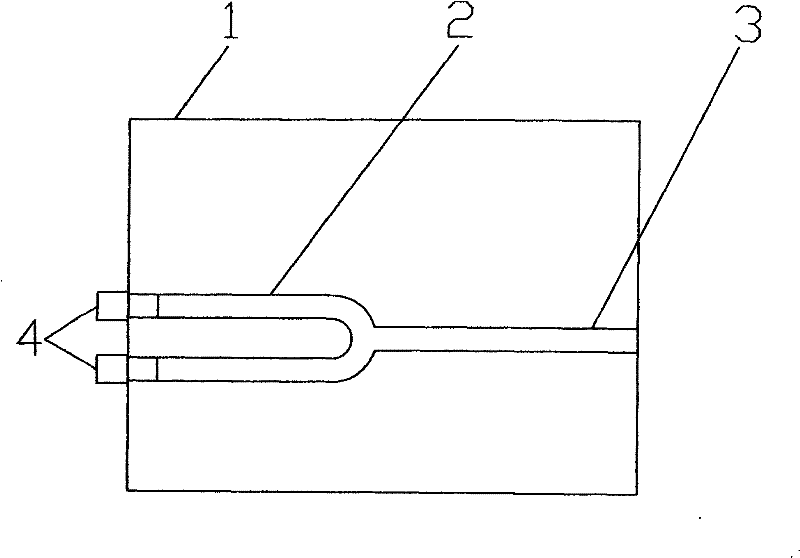

[0009] Referring to Fig. 1, a Y-shaped three-way forming mold of the present invention includes a mold body 1, a U-shaped groove 2 is arranged on the mold body 1, and the bottom of the U-shaped groove 2 is movably connected with a thimble 3, The two ends of the U-shaped groove 2 are movably connected with the thimble 4, and the thimbles 3, 4 are connected with the power device.

[0010] The above technical solution may also have the following improvement: the power device is a hydraulic cylinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com