Method for automatically selecting type of variable-force spring and determining type information

A variable force spring and model technology, applied in flexible shafts, special data processing applications, instruments, etc., can solve the problems of confusing changes in spring compression length, no selection report, and large workload, avoiding repetitive calculations. , the effect of saving computer memory and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

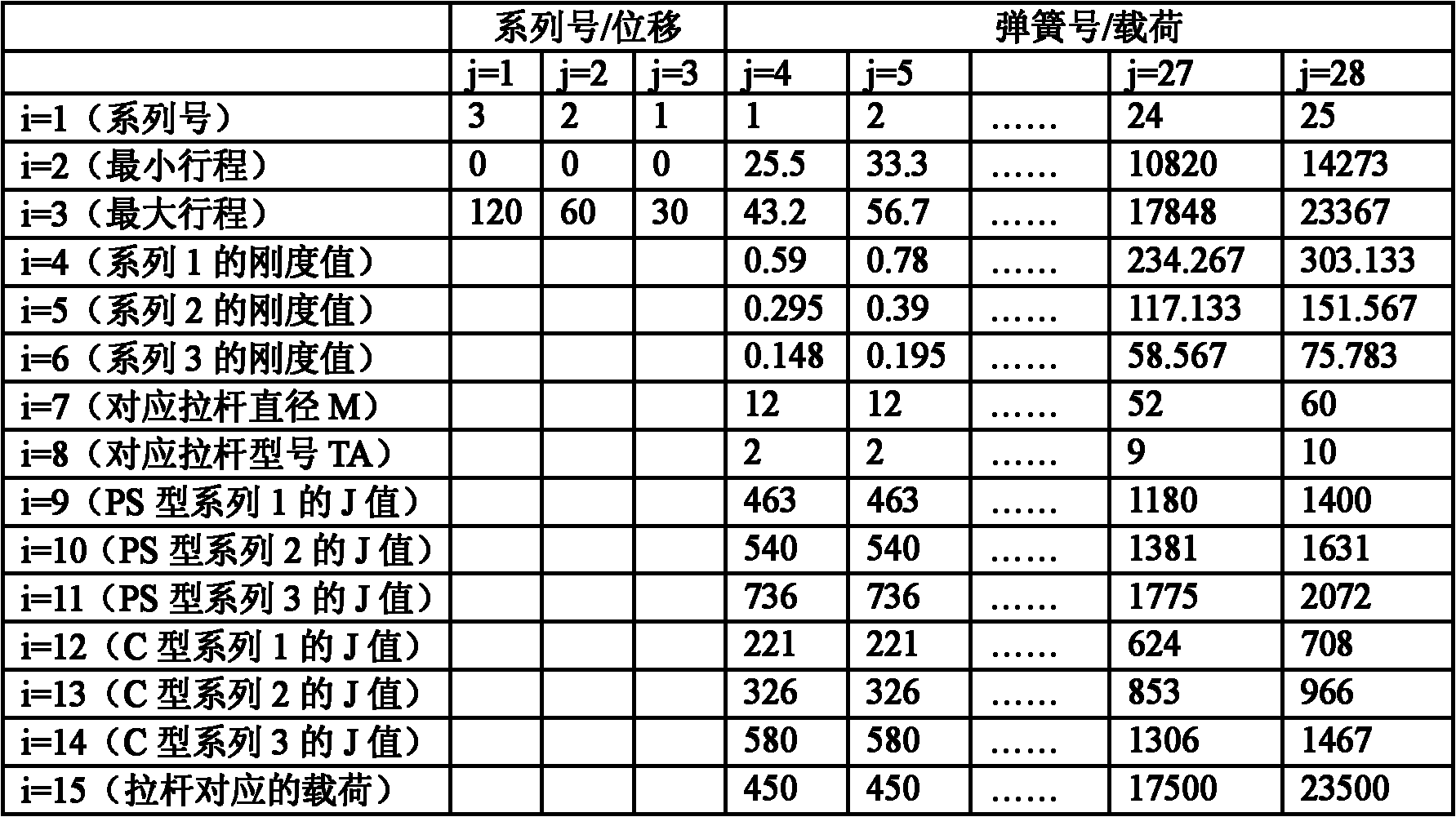

[0073] First define the performance parameters of the spring through the array SV[i, j]. In this embodiment, i and j are all defined serial numbers used to represent the performance parameters of the spring, including spring models and spring series; wherein, i≥1, 1≤j≤28, the specific definition is as follows:

[0074] When 1≤j≤3, the two-dimensional array SV[i,j] of i=1 represents the spring serial number, and the two-dimensional array SV[i,j] of i=2 represents the minimum stroke of the spring under the corresponding serial number; i The two-dimensional array SV[i, j] of =3 represents the maximum stroke of the spring under the corresponding serial number;

[0075] When 4≤j≤28, the two-dimensional array SV[i,j] of i=1 represents the specific spring model, and the specific spring model is j-3; the two-dimensional array SV[i,j] of i=2 represents The minimum spring load of the spring under the corresponding model; the two-dimensional array SV[i, j] of i=3 represents the maximum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com