Air flow full-seal-type smoke exhaust hood

A fully enclosed, fume exhaust hood technology, applied in the field of fume exhaust hoods, can solve the problems of blocking the operator's action and sight, operator hazards, cooking limitations, etc., to achieve the goal of improving uniformity, reducing hazards, and improving exhaust efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

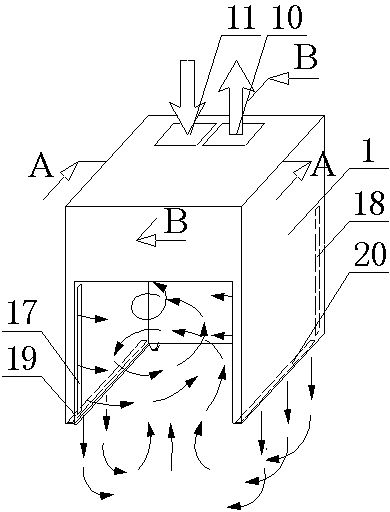

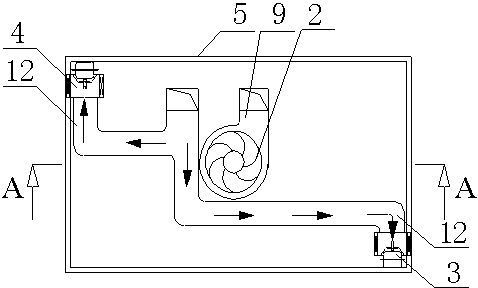

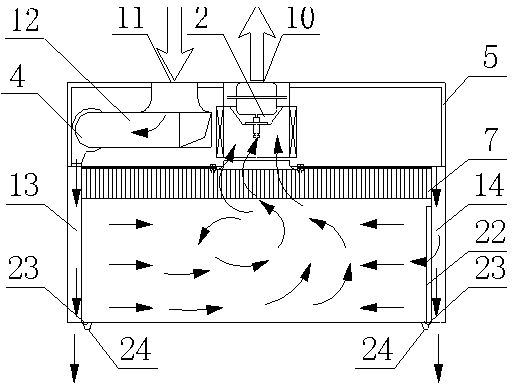

Embodiment 1

[0058] According to the actual use, the numerical calculation model of the airflow fully enclosed high-efficiency exhaust hood is established. The length × width × height of the room is 4800 × 2400 × 2400mm; The height of the lower edge from the ground is 1200 mm; the size of the first rectified plenum and the second rectified plenum are the same: length × width × height is 500 × 50 × 600 mm, and the length × width of the stove is 2400 × 600mm; the height of the cooktop from the ground is 900mm; the radius of the pollution source is 300mm, and the height of the pollution source is 1200mm. The speed is 1.5m / s. In this embodiment, the first air blower 4 and the second air blower 3 are installed in the top shell 5, and the first air direction adjustment baffle 21 and the first side slit air outlet 17 are located in the specific structure of the exhaust hood. The included angle of the plane is 75°, the included angle between the second wind direction adjusting baffle plate 21 and...

Embodiment 2

[0073] This embodiment differs from Embodiment 1 in that, under the condition that the air supply volume is kept constant, there is only one air supply fan in this embodiment, so as to reduce the initial investment.

Embodiment 3

[0075] The difference between this embodiment and Embodiment 1 is that the angle between the first wind direction adjustment baffle 21 and the plane where the first side slit air outlet 17 is located is 65°, and the second wind direction adjustment baffle 21 and the second side slit The included angle of the plane where the slit air outlet 17 is located is 65°, and the air curtain air supply angle is the incompleteness of the rotating air curtain formed when the included angle between the adjustment baffle plate and the plane where the side slit air outlet is located is 65°, and the control effect is poor. This is because when the air supply angle is small, the vortex nucleus becomes smaller, the rotation speed increases, and the disturbance of the air increases, which makes the flow field unstable and easy to cause harmful gases to escape. . Therefore, this embodiment shows that the air supply angle cannot be as small as possible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com