Valve cap of high-vacuum baffle valve

A baffle valve, high vacuum technology, applied in the direction of valve details, valve device, valve shell structure, etc., can solve the problems of increased shear force between threads, large valve opening and closing torque, laborious operation, etc., to prolong the service life, Reduce the shear force and solve the effect of laborious operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

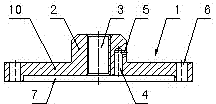

[0012] Such as figure 1 As shown, the bonnet of the high vacuum baffle valve of the present invention includes: a bonnet body 10, the bonnet body 10 is provided with an outwardly protruding 2, and a valve stem threaded hole 3 is provided in the middle part of the bonnet body 10. The ventilation hole includes the inner hole 4 opened along the direction of the valve stem threaded hole 3 and the outer hole 5 arranged radially; moreover, by reducing the diameter of the outer hole 5 and increasing the number of the outer hole 5, it is ensured that In order to ensure unimpeded ventilation, it can also reduce harmful substances such as dust from entering the valve body.

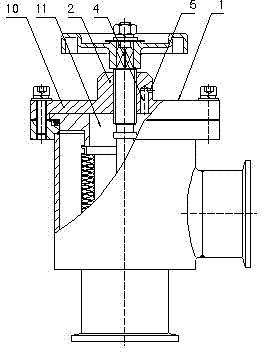

[0013] Such as figure 2 As shown, in the actual use of the high vacuum flapper valve with the bonnet 1 installed, the vent hole composed of the inner hole 4 and the outer hole 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com