Large-flow high-frequency response electrohydraulic vibration device based on parallel servo valves and control method

An electro-hydraulic vibration and servo valve technology, applied in the direction of fluid pressure actuation device, fluid pressure actuation system components, mechanical equipment, etc., can solve the problems of complex decoupling control, not allowing the use of multiple actuators in parallel, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

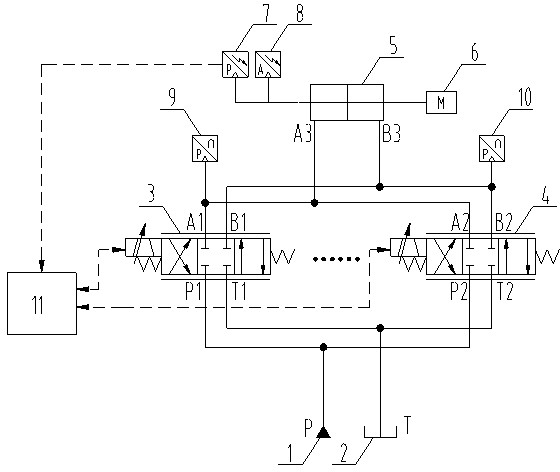

[0039] Such as figure 1As shown, the large-flow high-response electro-hydraulic vibration device based on the parallel connection of servo valves in the present invention includes an oil source 1, an oil return tank 2, more than two servo valves, a double-rod symmetrical hydraulic cylinder 5, a controller 11 and a displacement sensor 7; The oil inlet of each servo valve is connected with the oil source 1, the oil return port of each servo valve is connected with the oil return tank 2, and the first working oil port of each servo valve is connected with the first working oil port of the double-rod symmetrical hydraulic cylinder 5. One oil port is connected, and the second working oil port of each servo valve is connected with the second oil port of the double-rod symmetrical hydraulic cylinder 5; the displacement sensor 7 is connected with the piston rod of the double-rod symmetrical hydraulic cylinder 5; the displacement sensor 7 and each servo valve are electrically connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com