Rotary vane compressor

A compressor and rotary vane technology, applied in the field of compressors, can solve the problems of flexible impact, low volumetric efficiency, accelerated wear of compressor blades and cylinder blocks, etc., to achieve good sealing, ensure volumetric efficiency, and dynamic characteristic curves continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

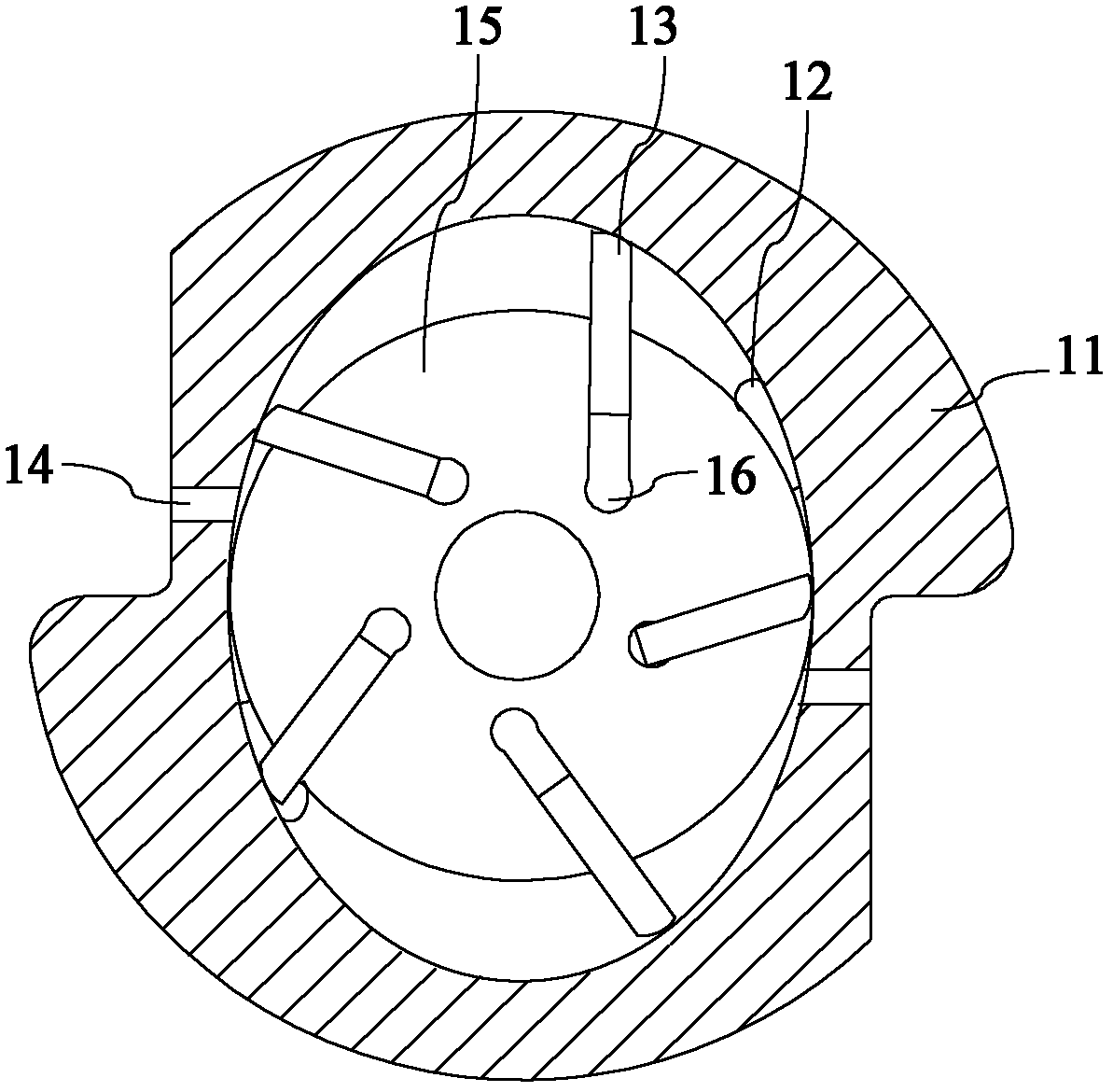

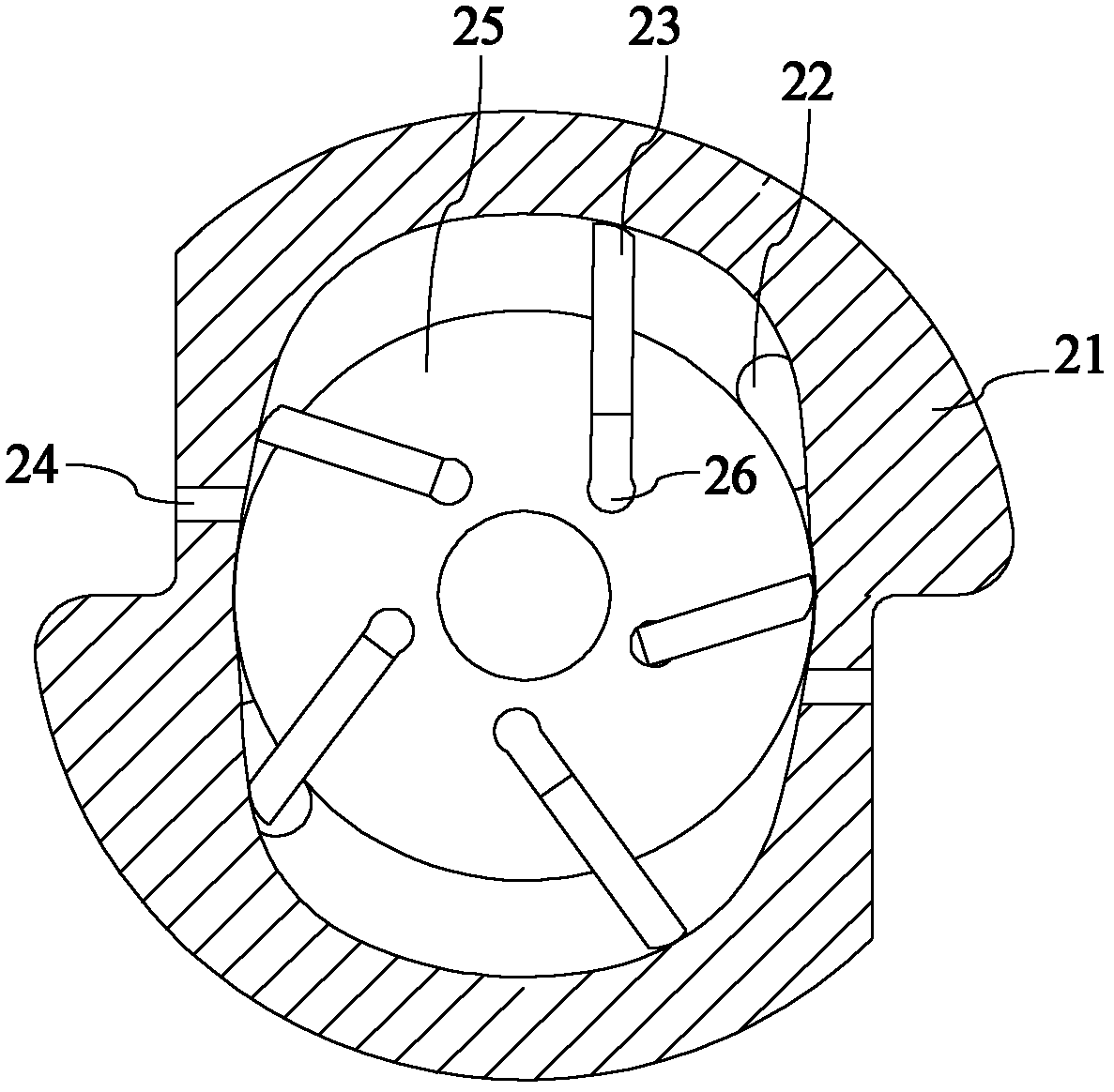

Embodiment 1

[0118] The rotary vane compressor in the embodiment is the same as the conventional 96-type rotary vane compressor in structural dimensions, namely: R=33.5mm; r=25.1mm; e=7.2mm; B=3.6mm; cylinder body width Lz= 40mm.

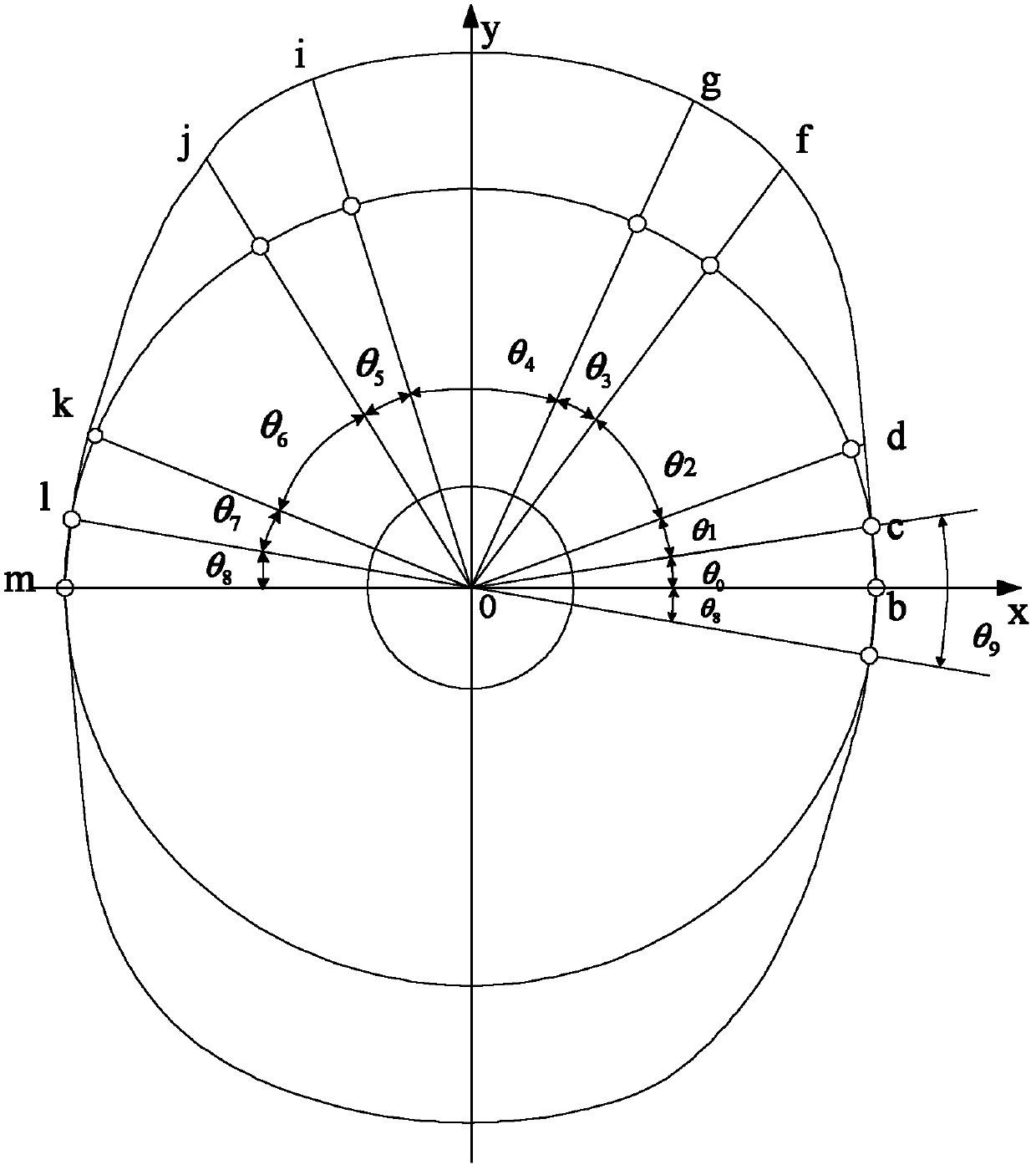

[0119] Pole diameter ρ of cylinder profile line and blade displacement S, pole angle θ and rotor rotation angle The relationship is as follows:

[0120]

[0121] Formula (9)

[0122] Through angle optimization, the corner span values of each segmental motion curve are obtained as follows:

[0123] θ 0 = 1 180 π θ 1 = 17 180 π θ 2 = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com