Method for increasing horizontal restraint and improving and determining bearing capacity of supporting frame

A technology of horizontal restraint and support frame, applied in the field of support frame, can solve the problems of increasing the corresponding relationship, safety accidents, and inability to determine the added value of critical load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

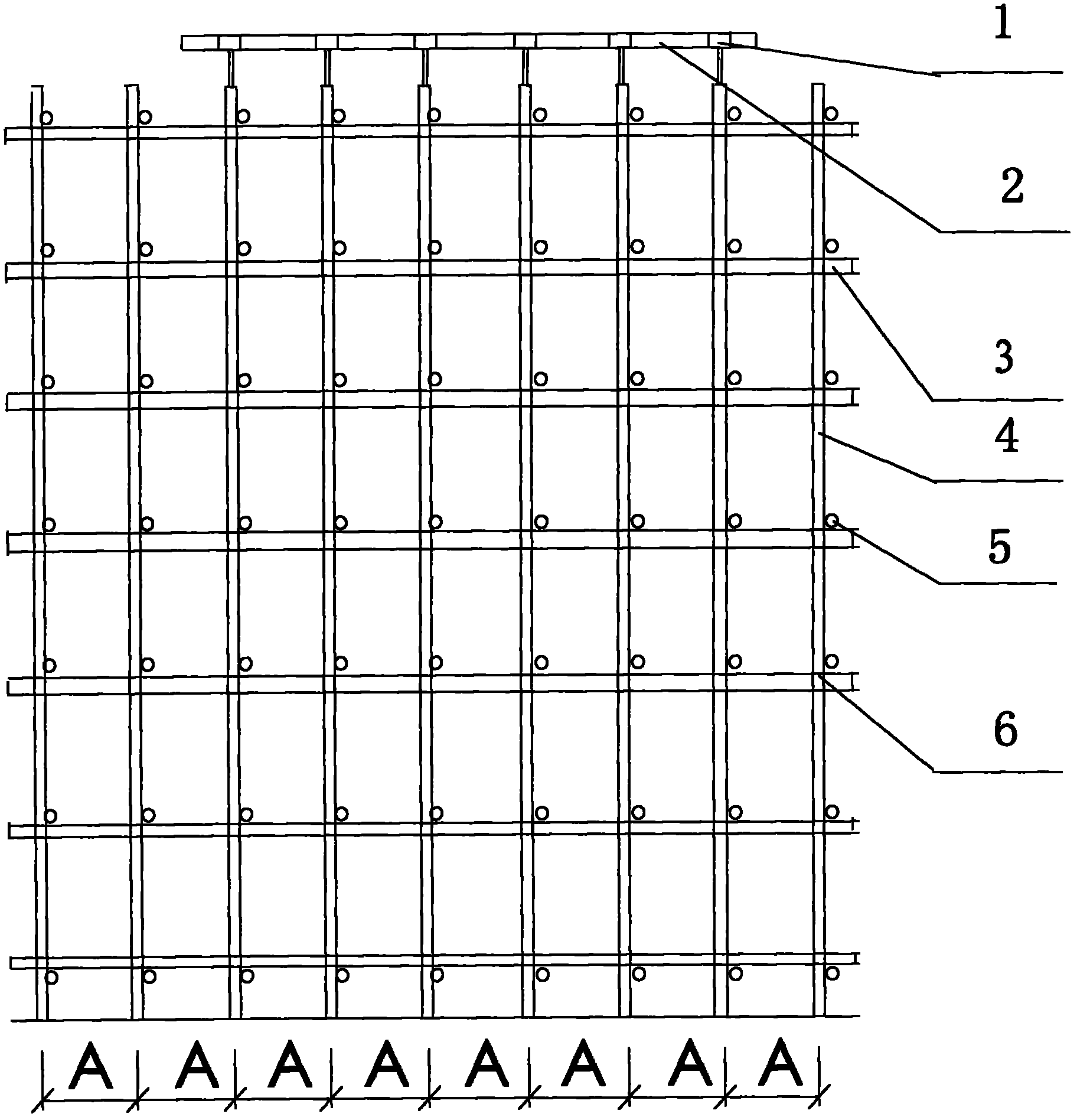

[0014] Such as Figure 1~5 As shown, the support frame adopts a fastener type steel pipe support frame, which includes a vertical steel pipe 4, a longitudinal horizontal rod 3, a horizontal horizontal rod 5, and a malleable cast iron fastener 6; the upper part of the bracket is supported by an adjustable bracket 1 Φ48×3.2 double steel pipes 2. The distance from the upper surface of the adjustable bracket to the bottom surface of the steel pipe of the vertical pole, that is, the height C is 8.2m, and the distance between the axis of the adjacent longitudinal horizontal pole or the adjacent horizontal horizontal pole, that is, the step distance E of the vertical pole is 1.24m, and the vertical pole The longitudinal spacing A of the steel pipes is 0.9m, the horizontal spacing B of the vertical pole steel pipes is 0.9m, and the height D of the sweeping pole is 0.2m.

[0015] The aspect ratio of the support=8.2÷(6×0.9)=1.5; the sweeping rod is the lower cross bar of the support, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical spacing | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com