Technology for producing substitution-degree hydroxyethyl cellulose

A high-degree hydroxyethyl and cellulose technology, applied in the field of high-substitution hydroxyethyl cellulose, can solve the problems that the degree of substitution can only reach 1.5-2.0, affect the application effect, and is not easy to control, so as to improve labor efficiency And the effect of production safety, shelf life extension, and mildew resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

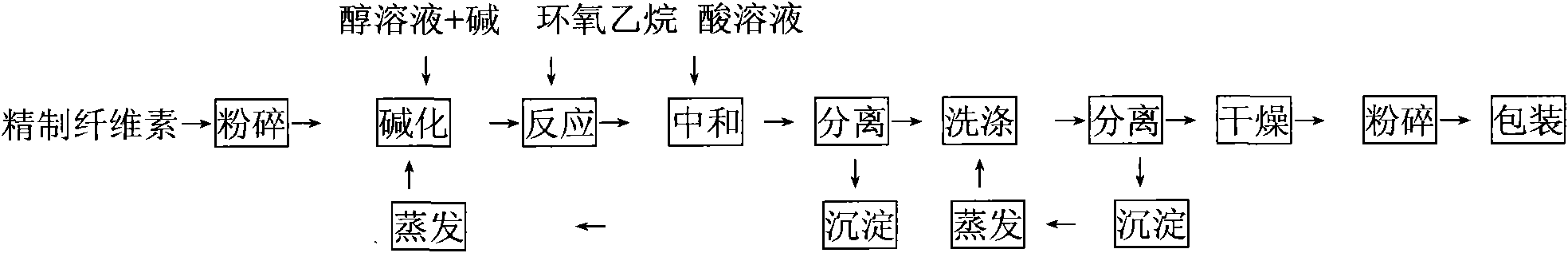

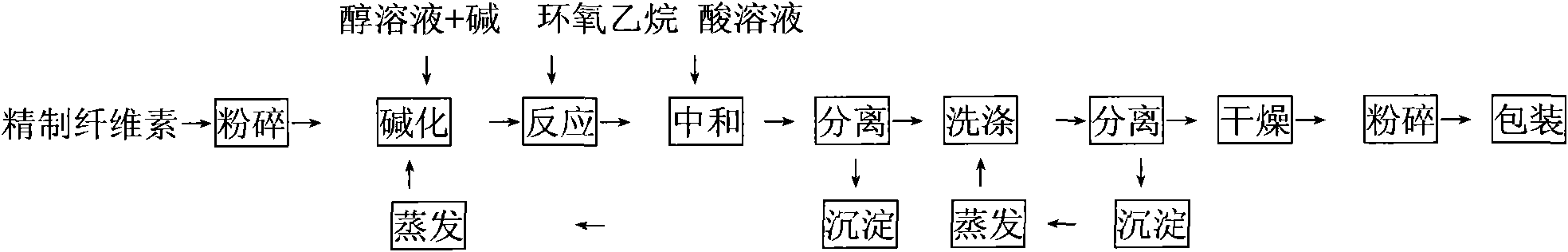

Image

Examples

Embodiment 1

[0032] (1) Pulverization: 1000 parts by mass of refined cellulose is pulverized with a rotary knife pulverizer, separated by a cyclone separator to reach 0.03-0.15mm (about 80 meshes), and the tail gas is subjected to bag dust removal;

[0033] (2) Alkalization: Add 5000 parts by mass of isopropanol solution into the reaction kettle and stir, add 200 parts by mass of caustic soda, heat up to 60°C for alkalization, after alkalinization, cool down to normal temperature, add step The pulverized refined cellulose obtained in (1) was alkalized at 20° C. for 0.5 hour;

[0034] (3) Reaction: divided into two steps,

[0035] First, add 40% oxirane of recipe amount in the reactor, this step reaction divides two stages, and the first stage is to react 1.5 hours under the situation that reaction temperature is 45 ℃, and the second stage is to react at reaction temperature React for 1 hour at 75°C;

[0036] Then, in the reactor, add the oxirane of formulation amount 60% again, this step...

Embodiment 2

[0044] (1) Pulverization: 1000 parts by mass of refined cellulose is pulverized with a rotary knife pulverizer, separated by a cyclone separator to reach 0.03-0.15mm (about 80 meshes), and the tail gas is subjected to bag dust removal;

[0045] (2) Alkalinization: Add 12000 parts by mass of n-propanol solution into the reaction kettle and stir, add 280 parts by mass of caustic soda, heat up to 70°C for alkalization, after alkalinization, cool down to normal temperature, add step The pulverized refined cellulose obtained in (1) was alkalized at 15° C. for 1.5 hours;

[0046] (3) Reaction: divided into two steps,

[0047] At first, add the oxirane of recipe amount 65% in the reactor, this step reaction is divided into two stages, and the first stage is to react 0.5 hour under the situation that reaction temperature is 60 ℃, and the second stage is to react at reaction temperature Reaction at 85°C for 0.5 hours;

[0048] Then, in the reactor, add the oxirane of formulation amou...

Embodiment 3

[0056](1) Pulverization: 1000 parts by mass of refined cellulose is pulverized with a rotary knife pulverizer, separated by a cyclone separator to reach 0.03-0.15mm (about 80 meshes), and the tail gas is subjected to bag dust removal;

[0057] (2) Alkalization: Add 10000 parts by mass of n-butanol solution into the reaction kettle and stir, add 250 parts by mass of caustic soda, heat up to 85°C for alkalization, after alkalinization, cool down to normal temperature, and add step The pulverized refined cellulose obtained in (1) was alkalized at 35° C. for 1 hour;

[0058] (3) Reaction: divided into two steps,

[0059] First, add 50% ethylene oxide in the reaction kettle, this step reaction is divided into two stages, the first stage is to react for 1 hour at a reaction temperature of 50°C, and the second stage is to react at a reaction temperature of 50°C. React for 1.5 hours at 65°C;

[0060] Then, in the reactor, add the oxirane of formulation amount 50% again, this step re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com