Method for preparing high-purity lactulose

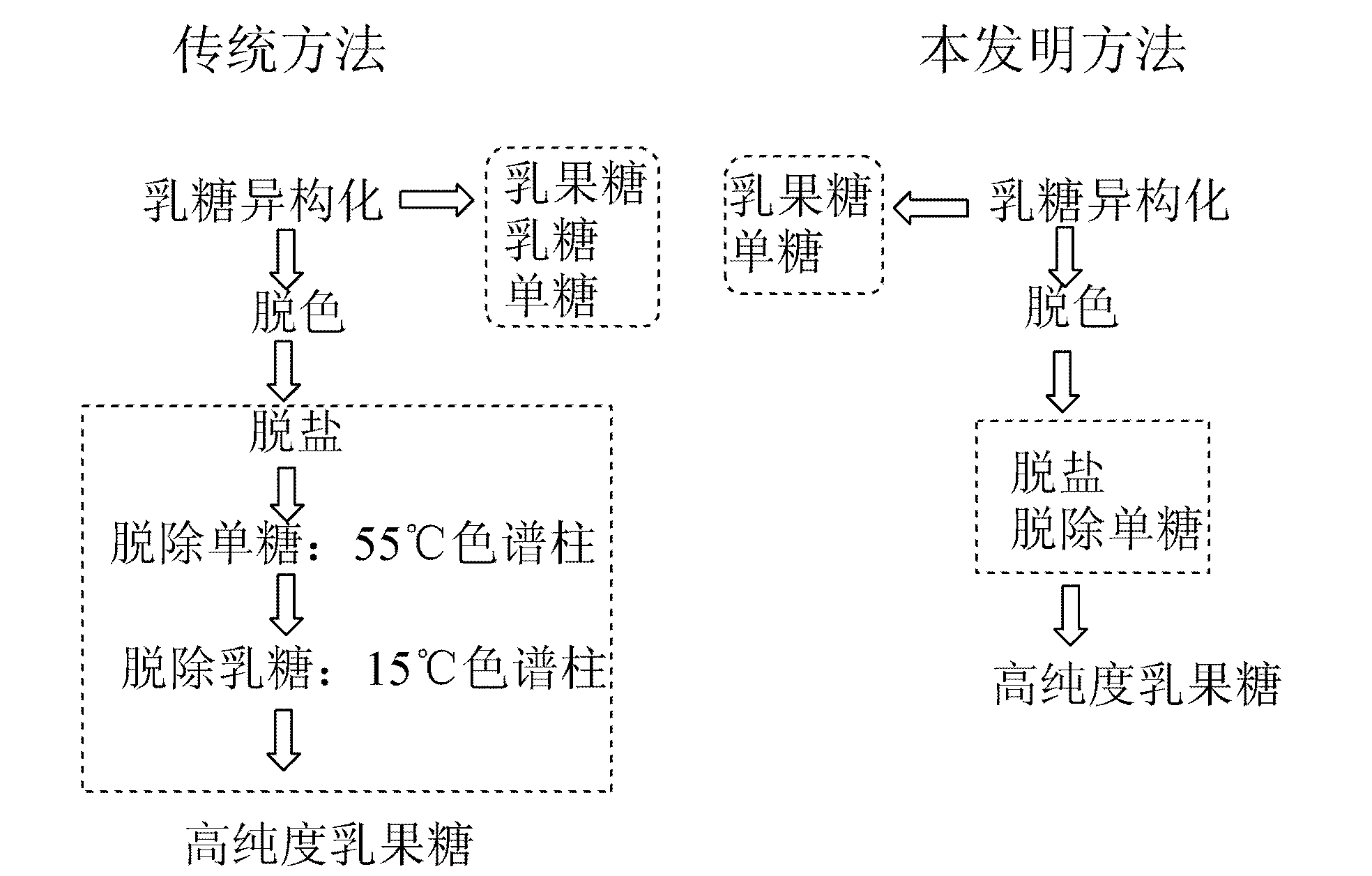

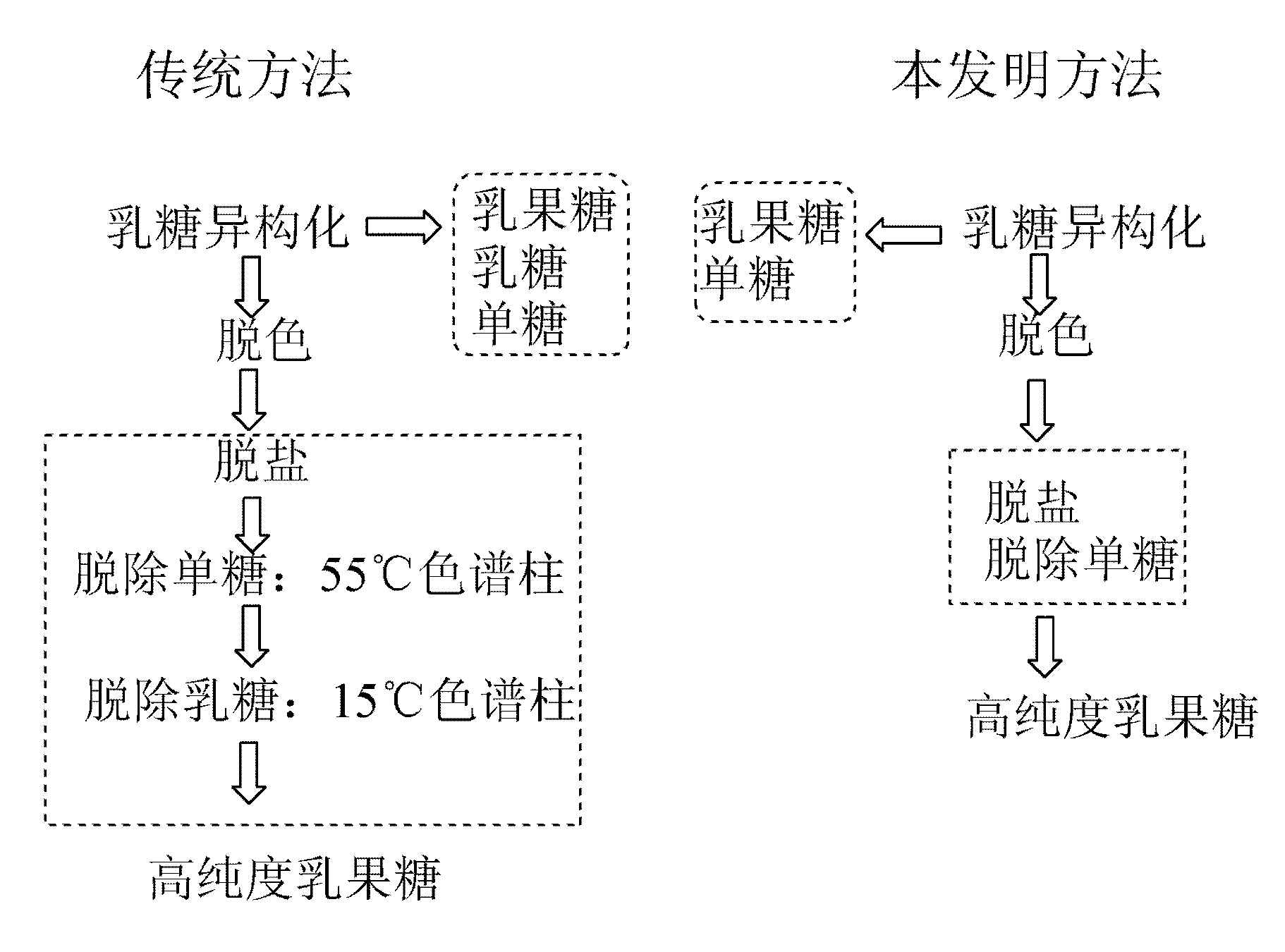

A lactulose, high-purity technology, applied in the field of preparation of high-purity lactulose, can solve the problem of high cost, and achieve the effect of simple production method, continuous production method and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A preparation method of high-purity lactulose, comprising the following steps:

[0019] (1) Preparation of lactulose syrup: use 4.6 kg of lactose as raw material, boric acid and sodium hydroxide as catalyst, including 0.69 kg of sodium hydroxide and 0.805 kg of boric acid (at this time, the molar ratio of boric acid and lactose is 1:1, and sodium hydroxide The molar ratio to lactose is 1.35:1), added to 22.5 L of water and heated to 70 °C to catalyze the conversion of lactose into lactulose syrup. The obtained lactulose syrup only contains lactulose and monosaccharides, and does not contain lactose ;

[0020] (2) Activated carbon decolorization: Cool the reaction solution to 50 °C, adjust the pH value to 3.2, add activated carbon with a mass ratio of 1% to the solid content for decolorization, and keep stirring for 2 h;

[0021] (3) Nanofiltration purification: import the syrup into the nanofiltration material liquid tank, use the M 8 series nanofiltration membrane to ...

Embodiment 2

[0025] A preparation method of high-purity lactulose, comprising the following steps:

[0026] (1) Preparation of lactulose syrup: use 10.0 kg of lactose as raw material, boric acid and sodium hydroxide as catalyst, including 1.65 kg of sodium hydroxide and 2.0 kg of boric acid (at this time, the molar ratio of boric acid and lactose is 1.2:1, and sodium hydroxide The molar ratio to lactose is 1.5:1), added to 49.0 L of water and heated to 50 °C to catalyze the conversion of lactose into lactulose syrup, the obtained lactulose syrup only contains lactulose and monosaccharides, and does not contain lactose ;

[0027] (2) Activated carbon decolorization: Cool the reaction liquid to 50 °C, adjust the pH value to 3.2, add activated carbon with a mass ratio of 1.5% to the solid content for decolorization, and keep stirring for 1.0 h;

[0028] (3) Nanofiltration purification: import the syrup into the nanofiltration material liquid tank, use the M 8 series nanofiltration membrane t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com