Technique for conditioning sludge by using synergic action of Fenton reagent and polyacrylamide

A polyacrylamide and sludge conditioning technology, which is applied in dehydration/drying/concentrated sludge treatment, oxidation treatment of sludge, etc., can solve the problems of difficult operation control and large sludge treatment volume, and achieve easy operation, increase solid Liquid separation ratio, the effect of reducing the amount of sludge treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

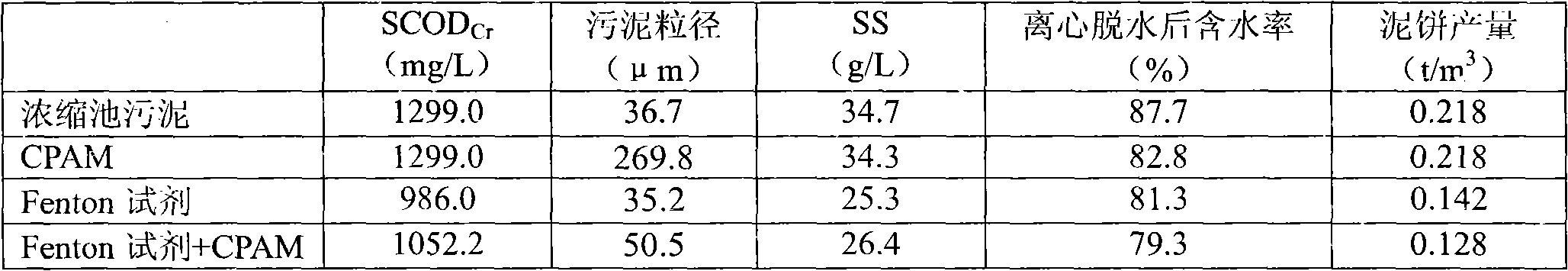

[0016] The sludge dewatering performance conditioning combination technology process described in the present invention makes full use of the respective advantages of Fenton reagent and CPAM, effectively oxidizes and degrades organic matter in sludge, releases bound water and water inside cells, and effectively decomposes sludge with small and dispersed particles Flocculate, enhance the dewatering performance of sludge, and increase the solid-liquid separation ratio in sludge dewatering. The present invention realizes sludge reduction, improves sludge dehydration performance, and provides better sludge form for subsequent sludge treatment and disposal under the optimal combined process conditions of combining the oxidation of Fenton's reagent and the flocculation of CPAM.

[0017] The operation process is shown in Figure 1. After the concentrated sludge is acidified, it is transported to the Fenton’s reagent oxidation tank. In the oxidation tank, the sludge reacts with the Fent...

Embodiment 1

[0019] The process of its operation is shown in Figure 1. After the sludge in the concentration tank is acidified by inorganic acid (pH=5), it is transported to the Fenton reagent oxidation tank (H 2 o 2 The dosage is 2g / L, FeSO 4 The dosage is 2.4g / L, and the reaction is 1 hour), the sludge in the oxidation tank reacts with Fenton's reagent under continuous stirring, the organic matter in the sludge is degraded, and the cell wall and extracellular polymers in the sludge (EPS) is dissolved and cracked, and a large amount of intracellular water and EPS bound water are released; when the Fenton reaction is complete, the sludge is flocculated and conditioned with CPAM (C8050 is added at 75mg / L, and the stirring method is 400rpm stirring Stirring at 60rpm for 5min after 30s), the dispersed fine particles in the sludge are adsorbed and flocculated to achieve good mud-water separation; then the sludge is transported to mechanical dehydration equipment for dehydration; finally, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com