Duct aerofoil system and aerial craft applying duct aerofoil system

An aircraft and wing technology, applied in the field of aircraft, can solve problems such as limited lift, inability to take off and land vertically, and heavy weight, and achieve the effect of smooth transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

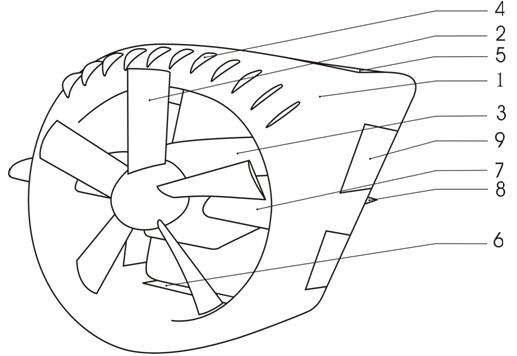

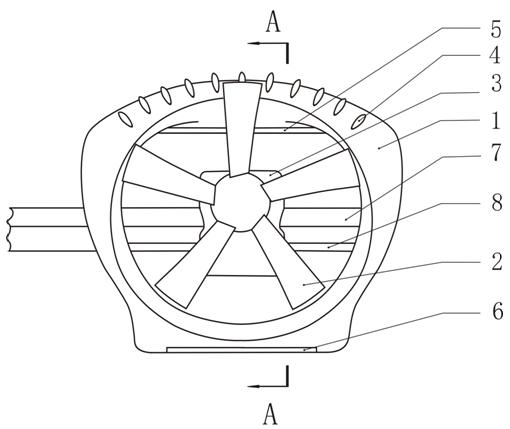

[0043] Embodiment 1: The aircraft has two ducted wing systems, and the two ducted wing systems are symmetrically arranged on both sides of the rear part of the fuselage 12 of the aircraft.

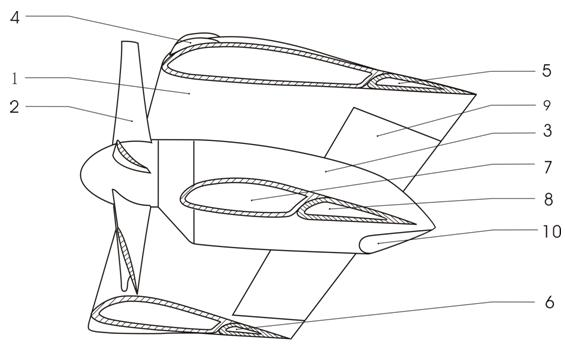

[0044] The specific installation method of the ducted wing system is: the extended section of the support wing 7 outside the ducted wing is connected with the back of the fuselage 12, and the ducted wing 1 is connected to the side below the side of the fuselage 12. There are inclined support wings 11 to support the angle, and the other end of the inclined support wings 11 is installed on the bulge on the side of the fuselage 12; there is a transmission shaft connection between the ducted wing fans 2 on both sides, so that the fans 2 on both sides can always maintain The same rotating speed; the ducted wing system on both sides of the aircraft has a dihedral angle, so that the aircraft has lateral stability when it takes off and lands vertically, hovers, advances at low speed, and flies hori...

Embodiment 2

[0051] Embodiment 2: The ducted wing system is one and the fuselage is used as the fan shaft to be arranged at the rear of the aircraft. Other structures of the aircraft are the same as in Embodiment 1, so that the volume of the aircraft is smaller.

Embodiment 3

[0052] Embodiment 3: There are four ducted wing systems, which are symmetrically arranged on both sides of the aircraft fuselage. The aircraft adopts a canard layout or a tandem wing layout, and there is no built-in ducted fan in the nose of the aircraft.

[0053] The two aircraft described in the second embodiment and the third embodiment can also realize vertical take-off and landing, horizontal flight, and smooth transition between the vertical take-off and landing and the horizontal flight state.

[0054]The inclined shape can also not be adopted between the upper part and the lower part of the leading edge of the ducted wing, and other structures are the same as in the embodiment, so that the fan of the ducted wing system can also accelerate the inner wall surface of the lower part of the ducted wing The airflow, and the airflow on the inner and outer walls of the upper half of the ducted wing can be accelerated, so that the ducted wing can generate a lot of lift, but if i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com