Estimation method for operational reliability of numerical control machine based on proportional hazards model

A CNC machine tool, failure rate technology, applied in metal processing mechanical parts, measuring/indicating equipment, metal processing equipment, etc., can solve problems such as no one raised

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention is described in detail below in conjunction with accompanying drawing.

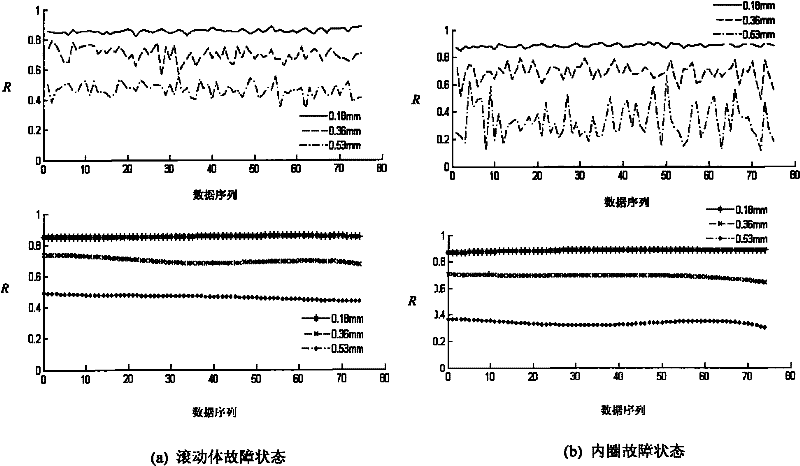

[0050] The method for evaluating the reliability of CNC machine tool operation based on the proportional failure rate model includes the following steps:

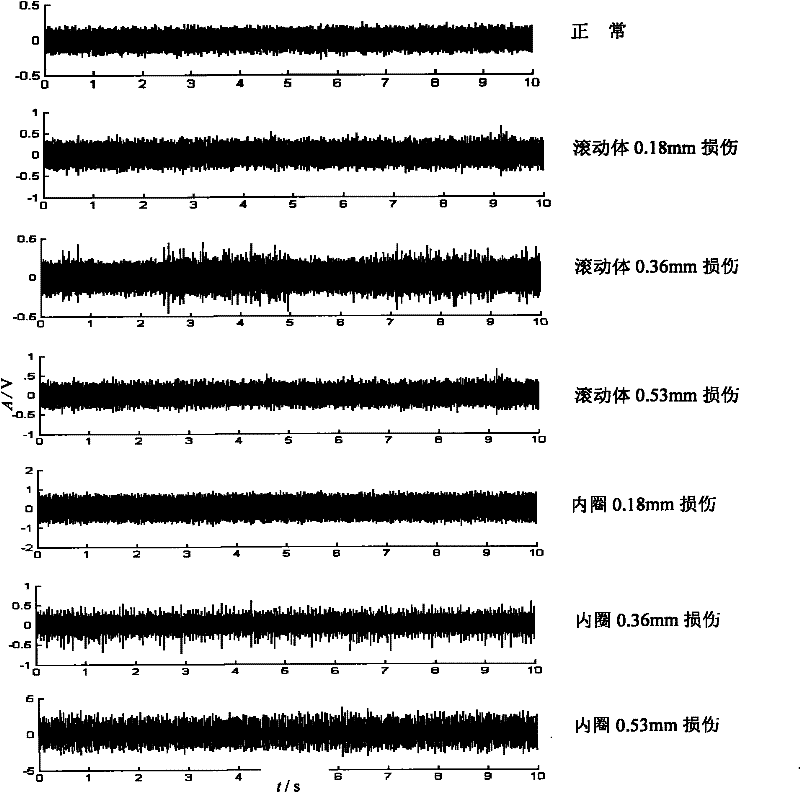

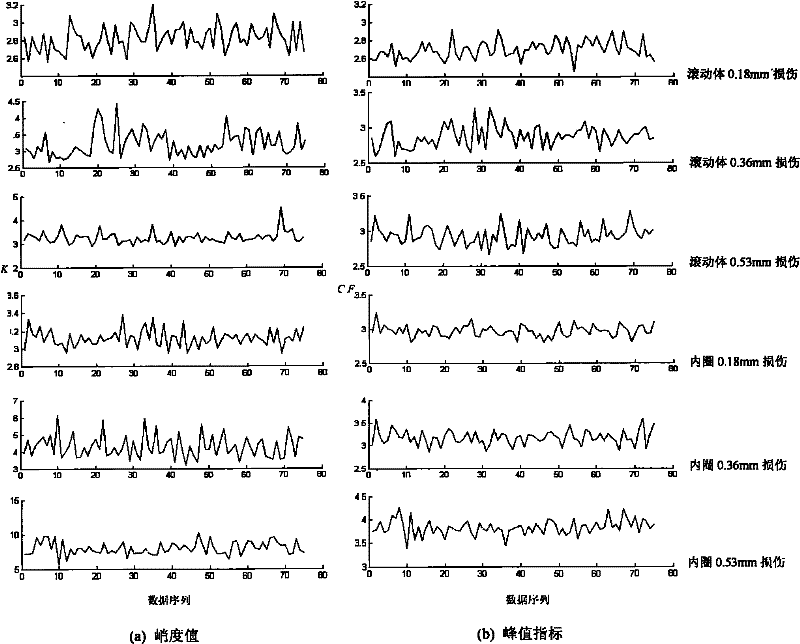

[0051] Step 1. Use the characteristic signal reflecting the operating state of the equipment, and select the four values of the effective value, peak value, kurtosis, and peak index in the characteristic signal as covariates in the proportional failure rate model;

[0052] The described use of the characteristic signal reflecting the operating state of the equipment, and the selection of the four values of the effective value, peak value, kurtosis, and peak index in the characteristic signal as covariates in the proportional failure rate model include the following steps:

[0053] Suppose a signal sequence S=(s 1 ,s 2 ,...,s t ,...,s T ), T is the signal length, then the RMS, peak, kurtosis, and peak indicators are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com