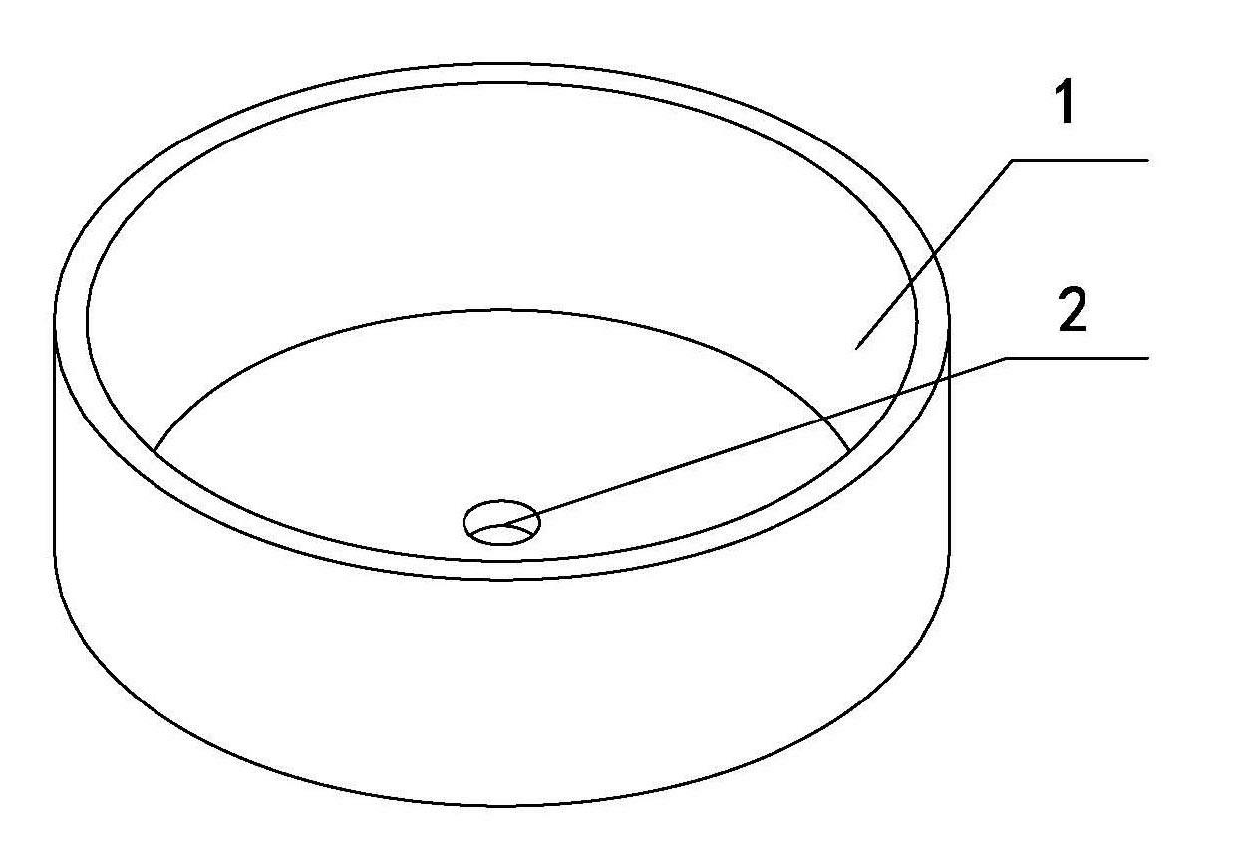

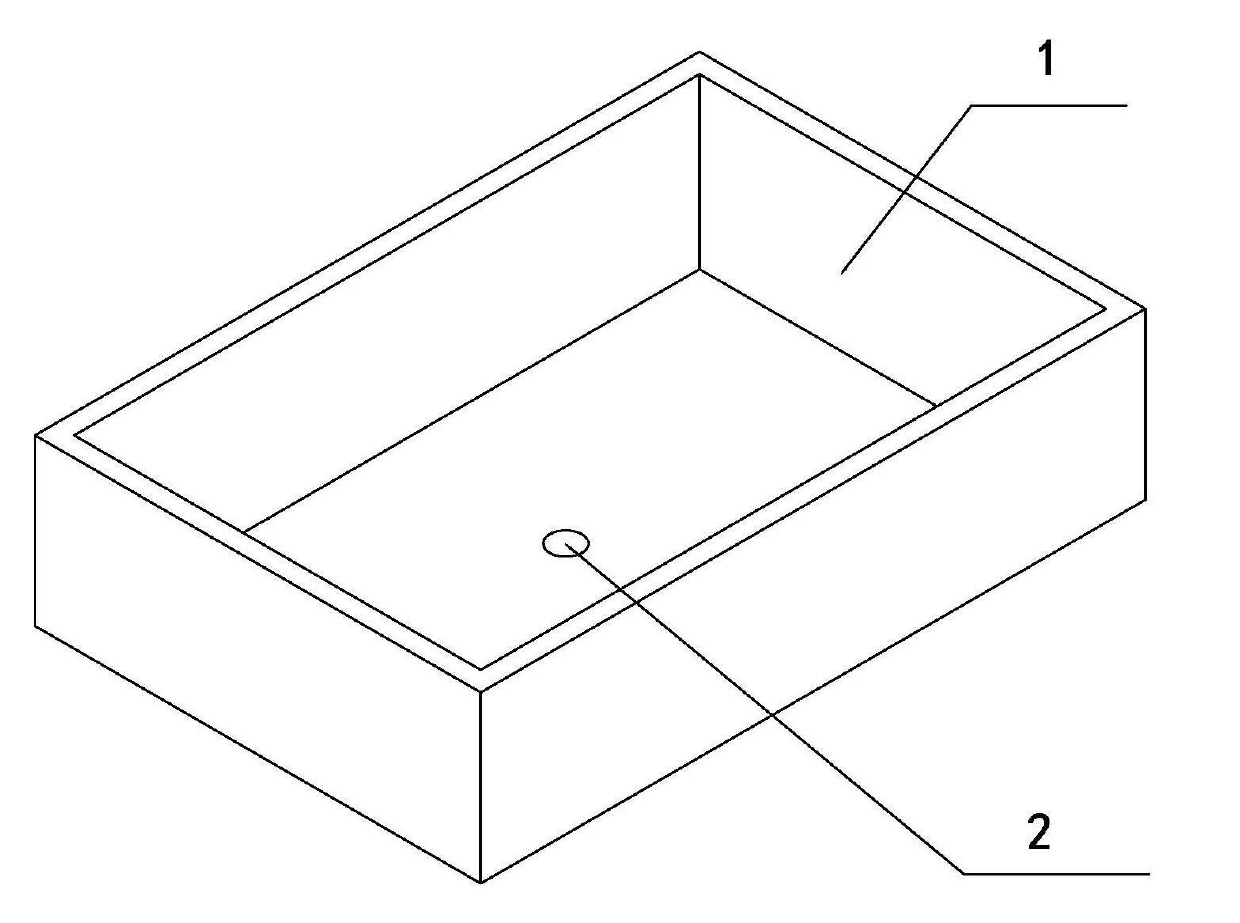

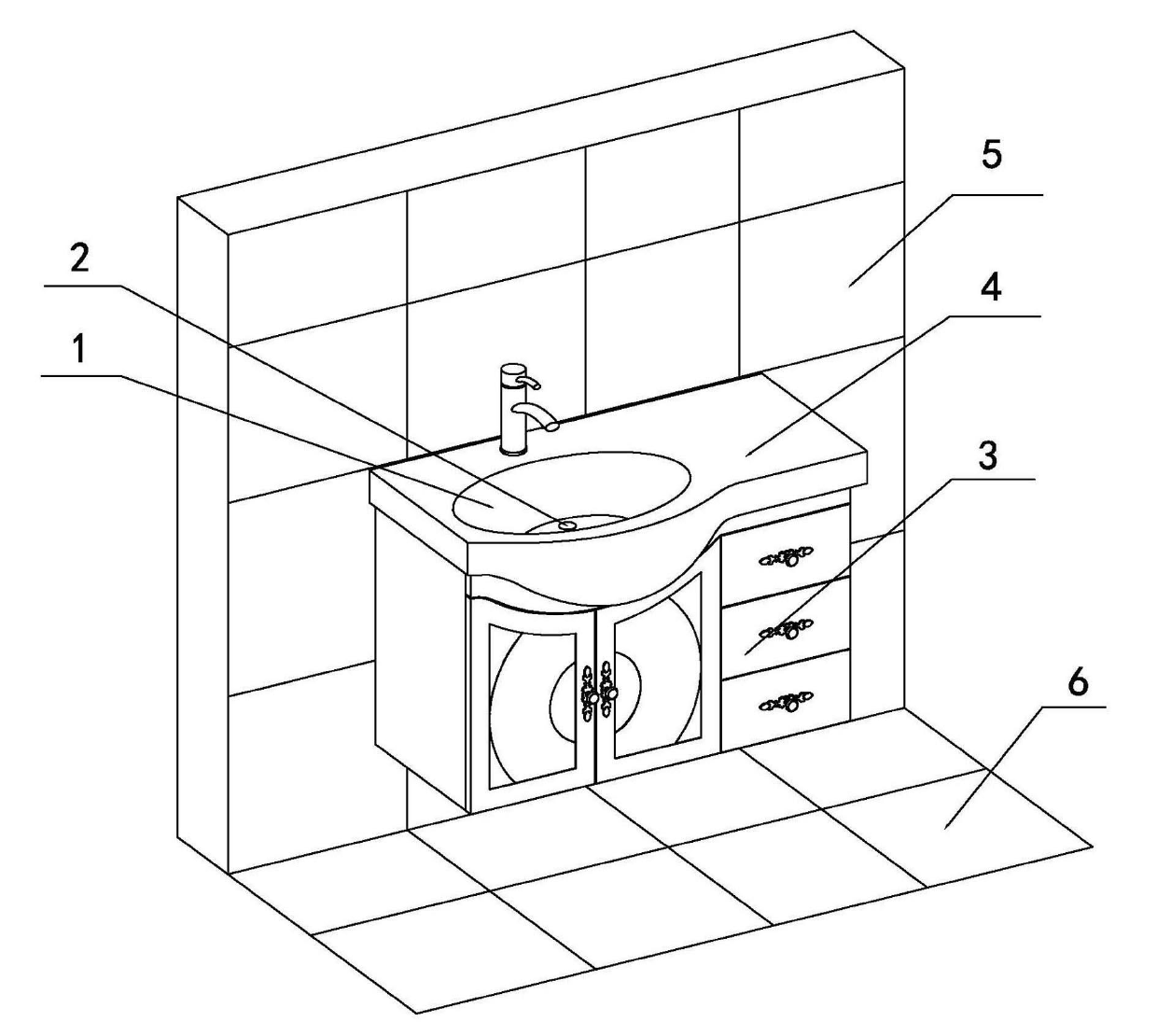

Plastic washbasin and manufacturing method thereof

A washbasin and plastic technology, applied in washbasin racks, applications, household appliances, etc., can solve the problems of high compatibility requirements for bathroom cabinets, easy damage to the washbasin, and glue traces left, etc., to achieve good compatibility and change the shape Convenient, easy-to-process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Chrysanthemum fragrance series: Chrysanthemum yellow (color number 3955C)

[0035] In this embodiment, the main raw materials are ABS with 65% by weight, PC with 35% by weight, toughener with 0.005% by weight and brightener with 0.002% by weight. During specific implementation, you can add 0.018% by weight of toner and 0.01% by weight of spices. After inspection, the washbasin produced is firm and durable, and the hardness can meet the requirements.

Embodiment 2

[0036] Example 2: Rose fragrance series: rose red (color number 813C)

[0037] In this embodiment, the main raw materials are ABS with 67% by weight, PC with 33% by weight, toughener with 0.008% by weight and brightener with 0.009% by weight. During specific implementation, you can add 0.02% by weight of toner and 0.008% by weight of spices. After inspection, the washbasin produced is firm and durable, and the hardness can meet the requirements.

Embodiment 3

[0038] Example 3: Violet series: purple (color number 2583C)

[0039] In this embodiment, the main raw materials are ABS with 69% by weight, PC with 31% by weight, toughener with 0.01% by weight and brightener with 0.007% by weight. During specific implementation, you can add 0.013% by weight of toner and 0.006% by weight of spices. After inspection, the washbasin produced is firm and durable, and the hardness can meet the requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com