Connecting and clamping device for conductive body, particularly conductive body with wire nose

A technology of clamping device and conductor, which is applied in the direction of clamping/spring connection, etc., can solve the problems of occupying space and occupying a lot of space, and achieve the effect of optimizing the installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

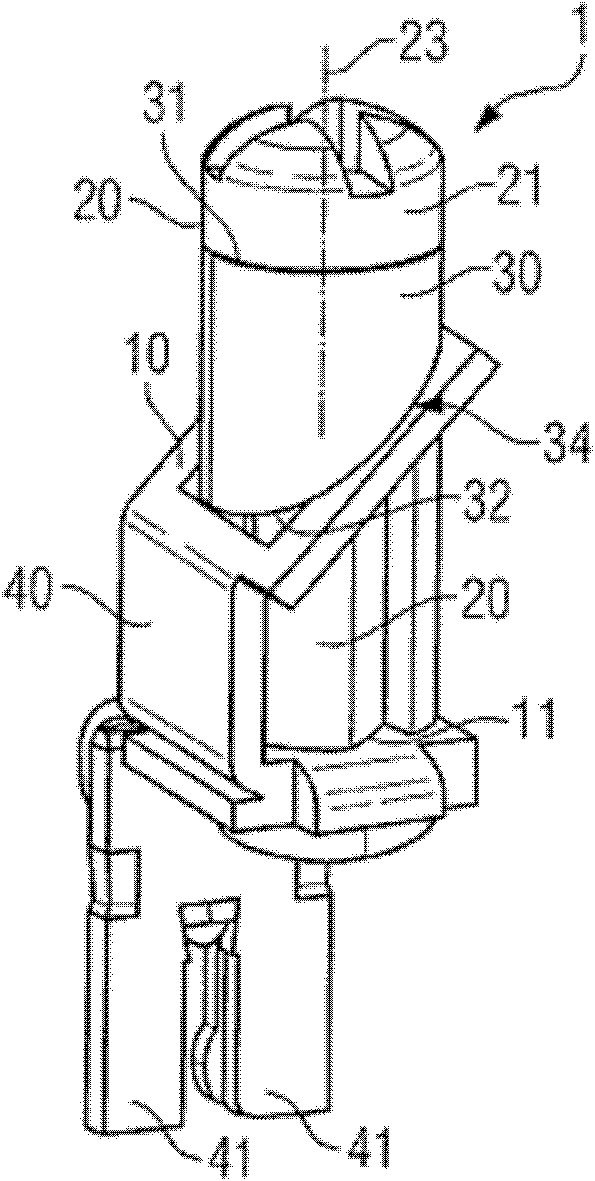

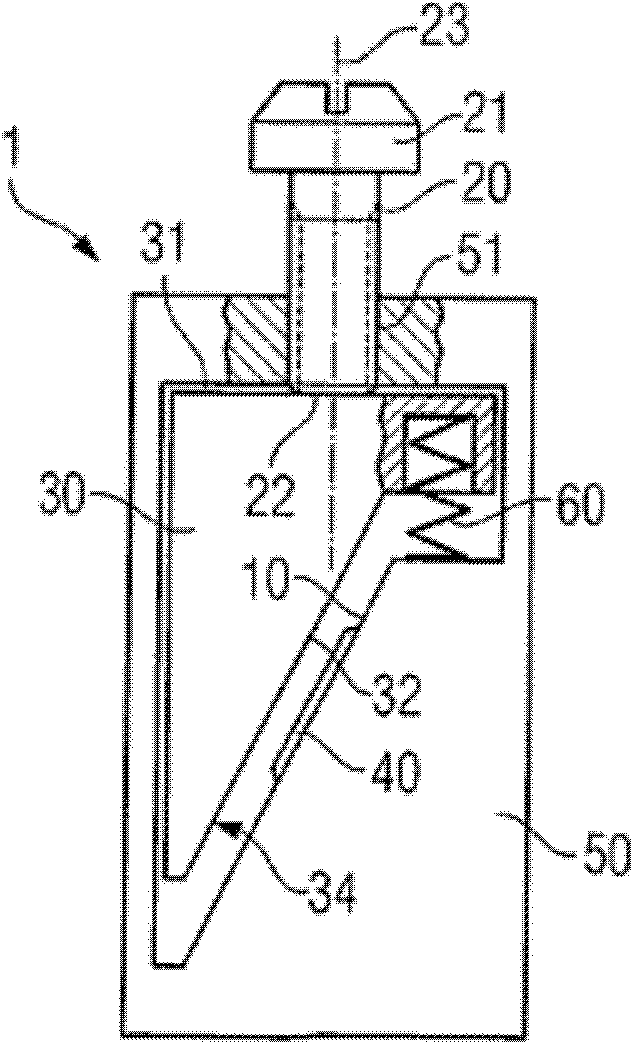

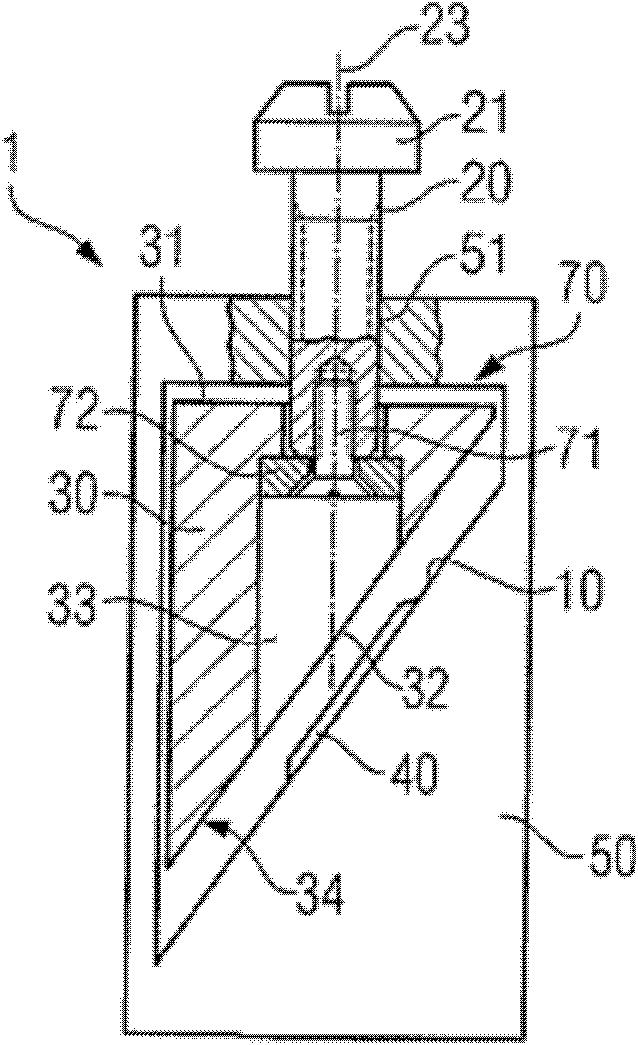

[0032] attached figure 1 Shown is a connection clamping device 1 comprising a clamping surface 10 , a clamping element 20 and a clamping part 30 . The clamping surface 10 is oblique at an angle to the longitudinal axis 23 of the clamping element 20 , which here is a clamping screw. The clamping element 20 is screwed into a threaded hole 11 on the clamping surface 10 . The clip 30 is inserted on the clamping element 20 , that is to say on the thread of the clamping screw. The clamping piece 30 thus has a hollow cylindrical shape, wherein the end face 31 of the clamping part 30 facing the clamping screw head 21 is straight and the end face 32 of the clamping part 30 facing the clamping surface 10 is inclined. The end face 32 of the clip part 30 facing the clamping face 10 can serve as a contact area 34 for an electrical conductor or a wire lug. The clamping surface 10 has at least one region oblique to the longitudinal axis 23 of the clamping element 20 . By means of the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com