On-line detection system and detection method for pipe (bar) ultrasonic phased array

An ultrasonic phased array and detection system technology, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measuring devices. Scanning and other issues to achieve the effect of improving detection speed and detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A pipe (rod) material ultrasonic phased array on-line detection system and detection method of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

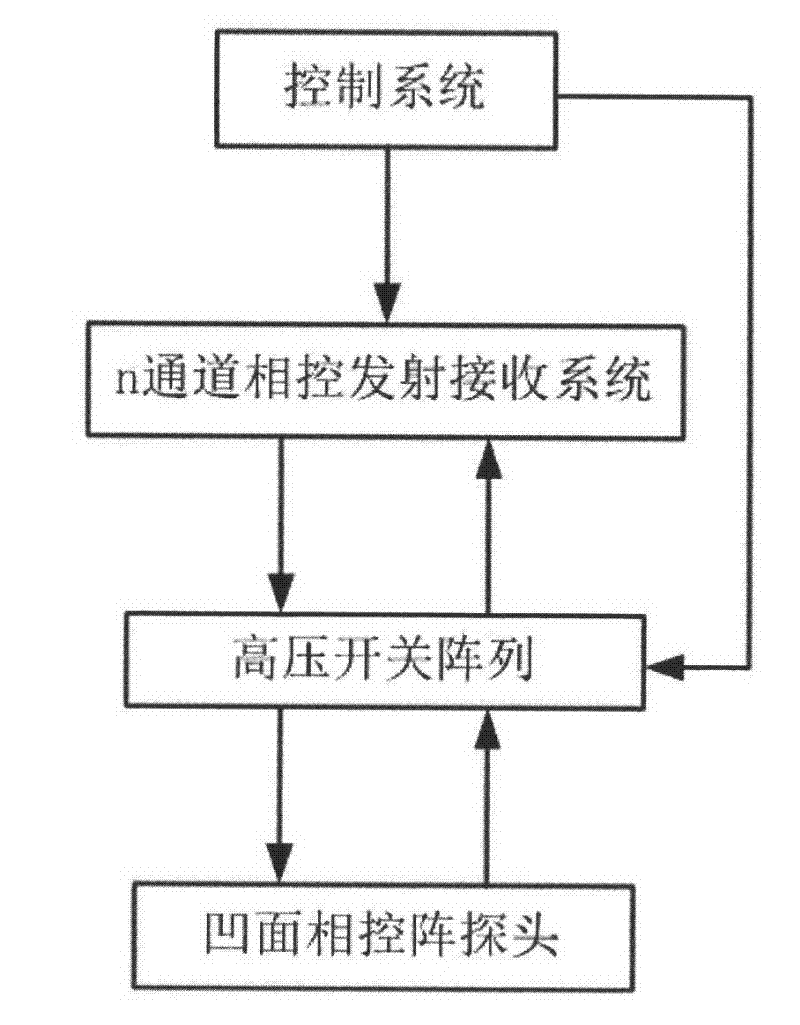

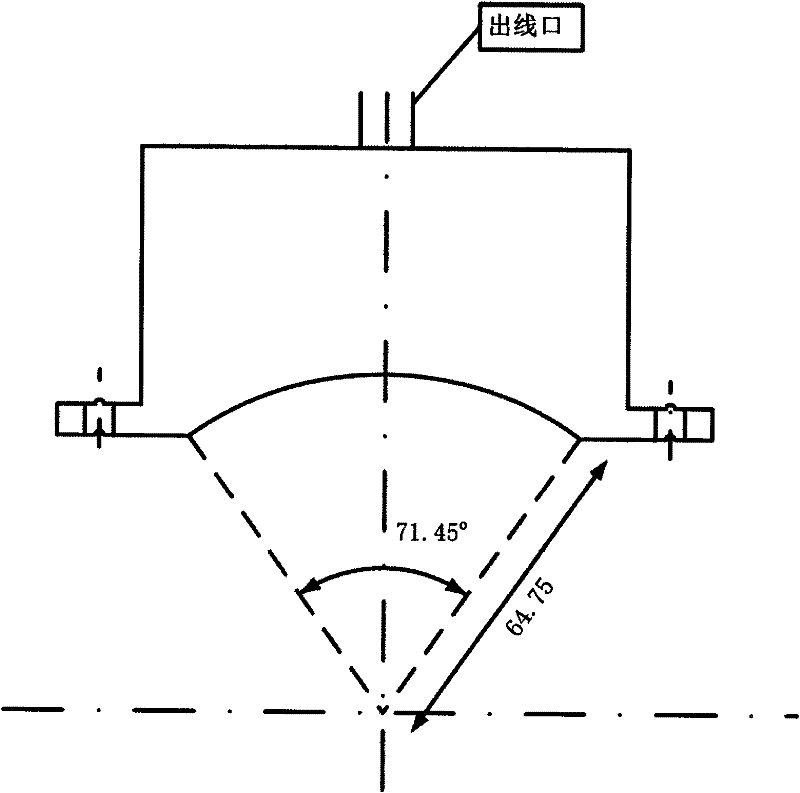

[0025] figure 1 It is a schematic diagram of the composition of the ultrasonic phased array on-line detection system for pipe (rod) material of the present invention. Such as figure 1 As shown, the ultrasonic phased array on-line inspection system for pipe (rod) material of the present invention includes: multiple concave phased array probes, a high voltage switch array, a multi-channel phased array transmitting and receiving system and a control system. By arranging multiple concave phased array transducer probes around the pipe, the concave ultrasonic phased array transducer probes are used to generate a phased array focused electronically controlled sound field, and at the same time, the multiple switches are controlled by the high-voltage switc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com