Large-sized combined dynamic and static multifunctional geotechnical engineering simulation testing device

A geotechnical engineering and simulation test technology, which is applied in the field of large-scale combined dynamic and static multifunctional geotechnical engineering simulation test devices, can solve the problems of high cost, unfavorable test line, and high processing precision requirements, so as to ensure the overall rigidity and strength, Improve test accuracy and good impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0060] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

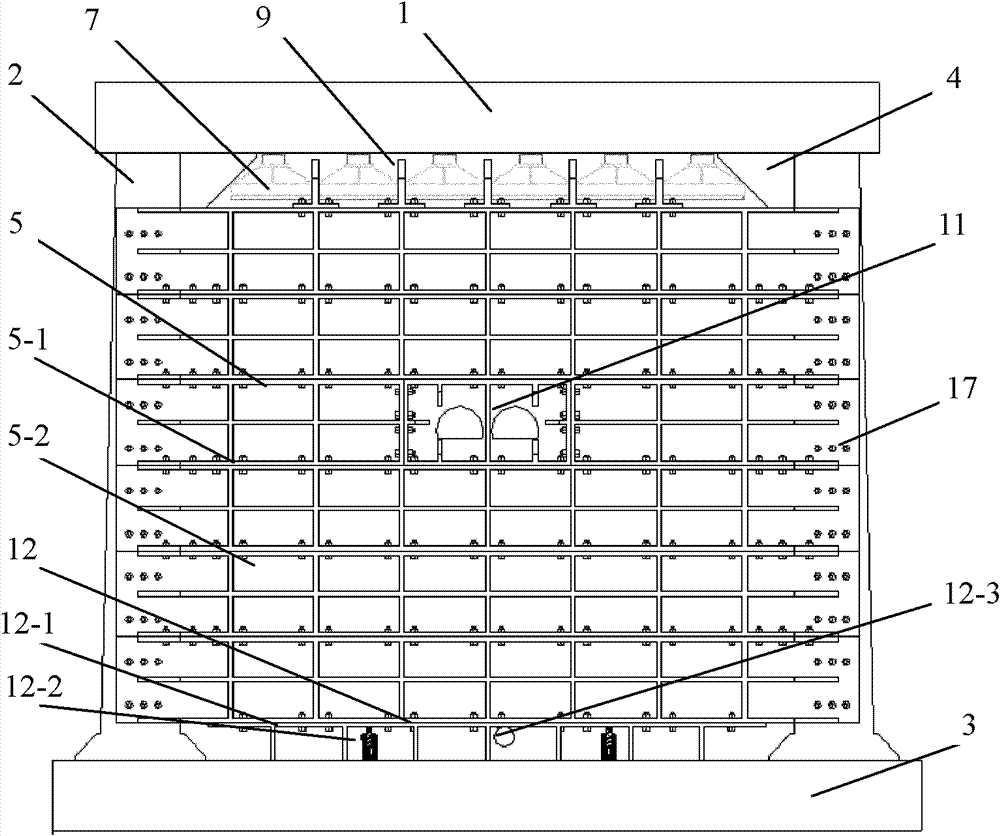

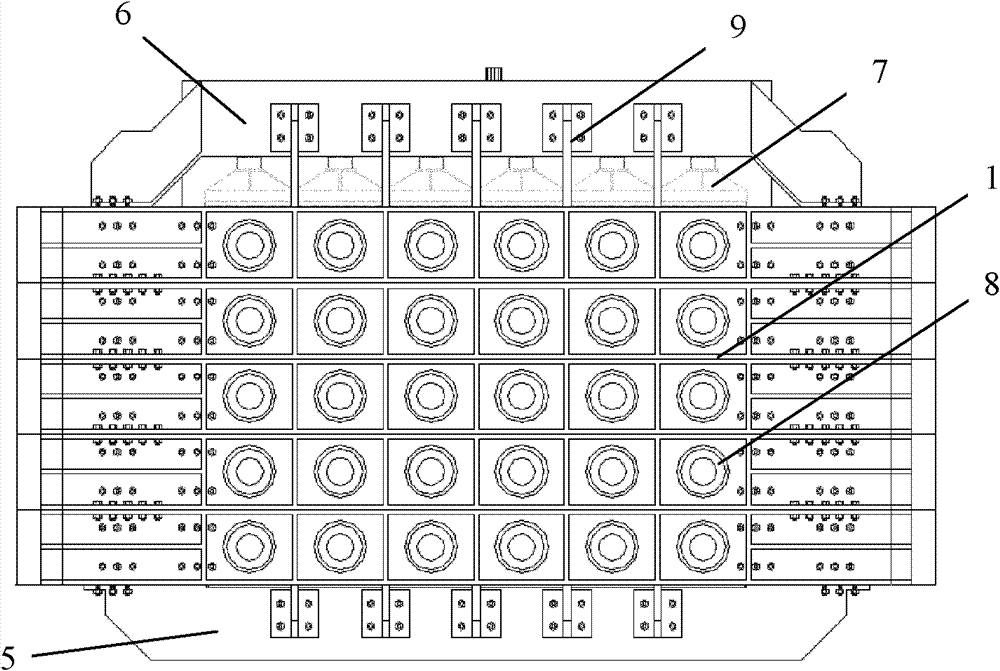

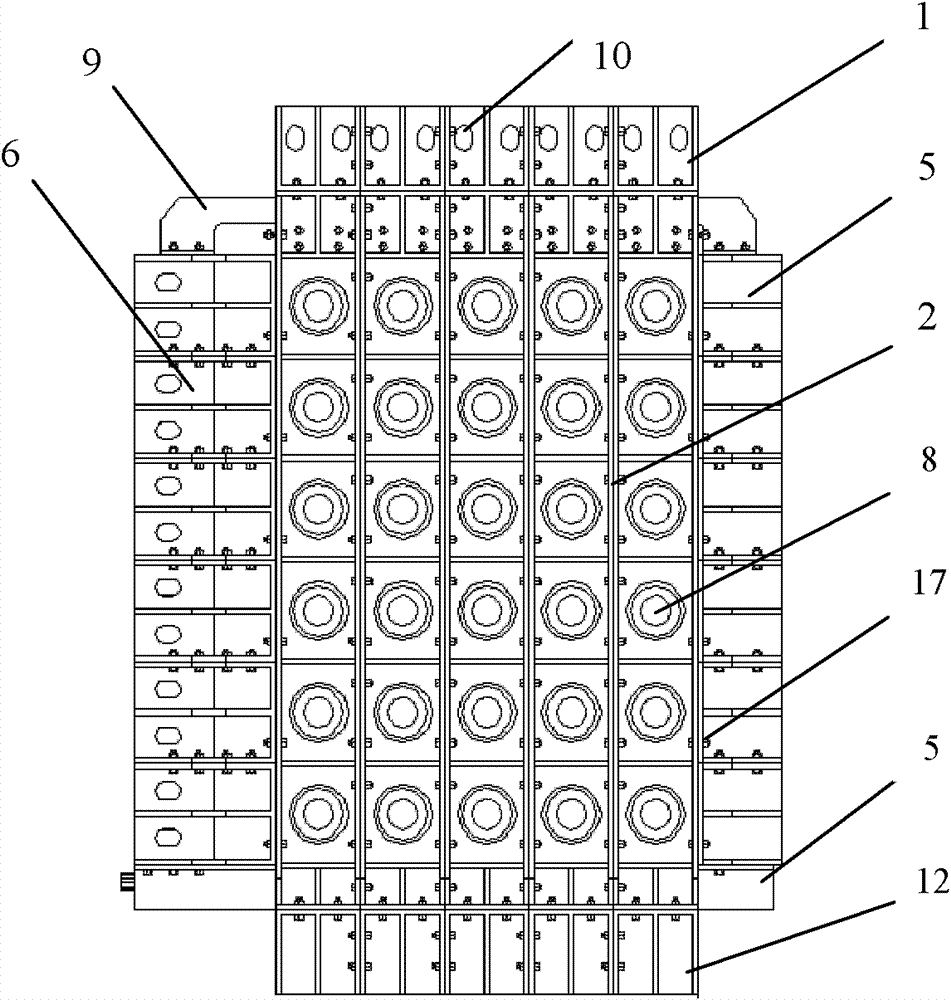

[0061] figure 1 , figure 2 , image 3 Among them, the large-scale assembled multifunctional geotechnical engineering model test device is mainly composed of an assembled reaction force bench device, a hydraulic loading system and a model transfer system. As a whole, the assembled reaction force platform device is narrow at the top and wide at the bottom, and the side is inclined. 1 and side beam 2 and between side beam 2 and bottom beam 3 are connected by flange 4 and high-strength connecting bolts 17; front visible reaction beam 5 and rear loading reaction beam 6 are connected to The side beam 2 is connected, and the bottom is connected with the model lift and translation trailer system 12; a hydraulic loading system 7 is installed in the steel grid of the top beam 1, side beam 2 and rear loading reaction beam 6; Load the system. The hydraulic lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com