Antibacterial composite film used for vacuum packing of household articles and preparation method thereof

A technology of vacuum packaging and composite film, which is applied in the direction of packaging, transportation and packaging, and special packaging objects under vacuum/special atmosphere, which can solve the problems of poor folding fatigue resistance, easy deformation of composite film, and easy air leakage, etc. Good effect, good vacuum sealing effect, excellent sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

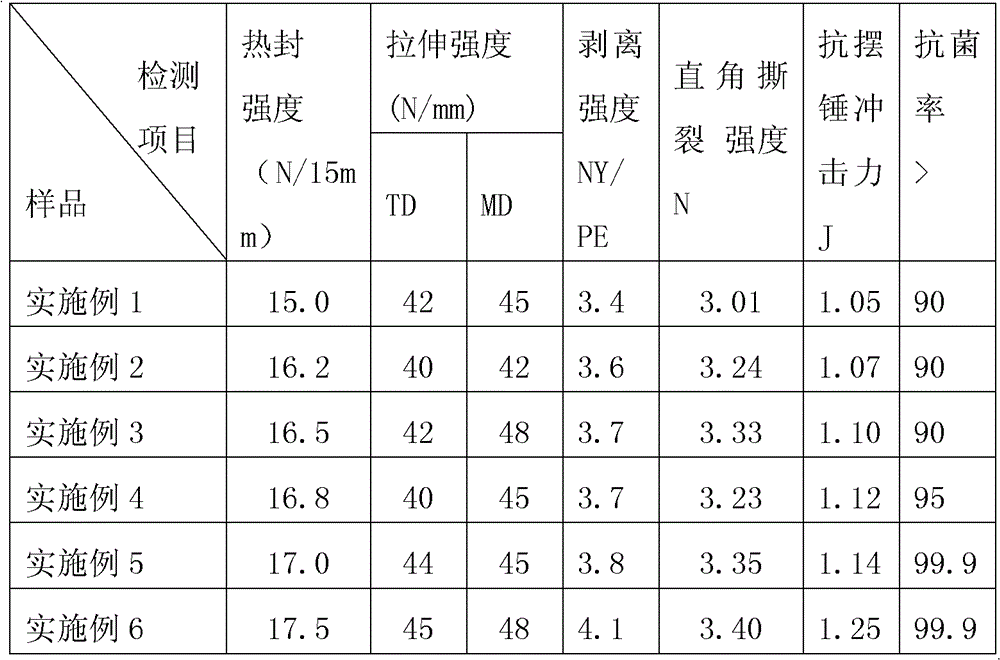

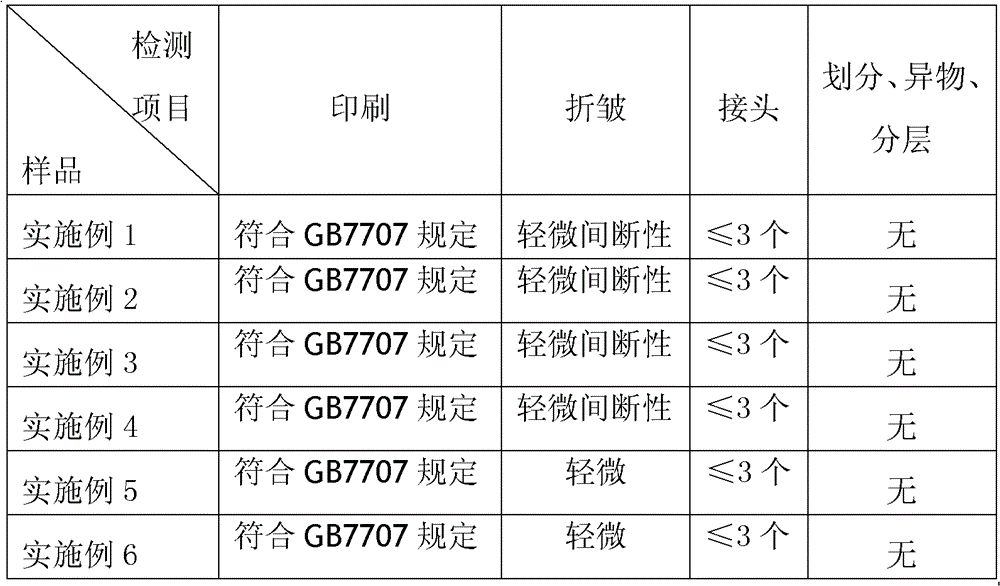

Examples

Embodiment 1

[0048] A preparation process of a novel antibacterial composite film that can be used for vacuum packaging of household articles is as follows: 1) preparation of antibacterial heat-sealing film; 2) printing process of biaxially stretched polyamide film; 3) extrusion compounding process.

[0049] The preparation process of the antibacterial heat-sealing film includes a batching process, a material plasticizing extrusion process, an inflation traction process, an air ring cooling process, a herringbone splint process, a rotating traction roller traction process, a corona treatment process, and a film winding process.

[0050] In the feeding process:

[0051] The outer layer adopts the formula weight ratio blending of LDPE:LLDPE=1:1;

[0052] The middle layer is blended with a formula weight ratio of HDPE:LDPE=1:1;

[0053] The inner layer is blended in a formula weight ratio of LDPE, MDPE, anti-blocking agent and antibacterial agent=3:1:0.05:0.05;

[0054]In the material plast...

Embodiment 2

[0057] The outer layer is blended with a formula weight ratio of LDPE:LLDPE=1:1.5;

[0058] The middle layer is blended with a formula weight ratio of HDPE: LDPE=1: 1.0;

[0059] The inner layer is blended with LDPE, MDPE, opening agent, antibacterial agent = 3: 1.5: 0.05: 0.08, and the rest are the same as in Example 1.

Embodiment 3

[0061] The outer layer is blended with a formula weight ratio of LDPE:LLDPE=1:1.5;

[0062] The middle layer is blended with a formula weight ratio of HDPE: LDPE=1: 1.5;

[0063] The inner layer is blended in a formula weight ratio of LDPE, MDPE, anti-blocking agent and antibacterial agent=3:1.5:0.05:0.08;

[0064] In the extrusion compounding process: when the resin temperature is controlled at 340°C and the circulating cooling water temperature is controlled at 18°C in the extrusion hot-melt film process, the peel strength is better after compounding with the coated base film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com