Vision-based track plate numerical controlled grinder optimization grinding method

A technology of CNC grinding machine and track plate, which is applied in grinding machine, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of optimization errors, inability to visually see the optimization results, and grinding out unsatisfactory track plate scrap plates, etc. To achieve the optimal grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical scheme of the present invention is further described in conjunction with the accompanying drawings.

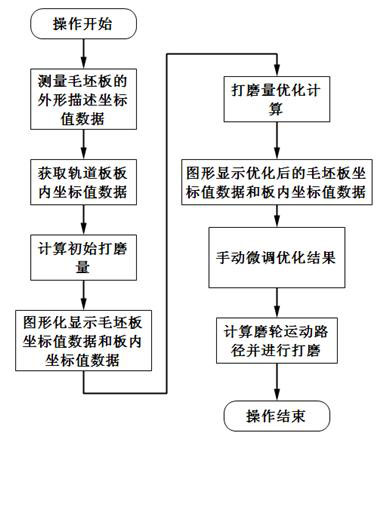

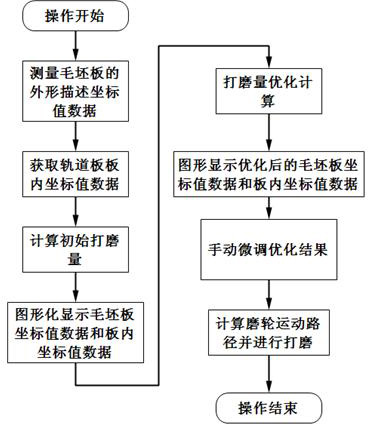

[0025] figure 1 The operation process of the method for optimizing the grinding of track slabs involved in the present invention is shown, as figure 1 As shown, the technical steps of the visualization-based orbital slab numerical control grinding machine optimization grinding method involved in the present invention include: measuring the outline description coordinate value data of the rough slab, obtaining the inner coordinate value data of the orbital slab, calculating the initial grinding amount, and graphical display Rough plate coordinate value data and in-plate coordinate value data, optimization calculation of grinding amount, graphic display of optimized rough plate coordinate value data and in-plate coordinate value data, manual fine-tuning of optimization results, calculation of grinding wheel motion path and grinding.

[0026] The measurement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com