Self-compensating servo wiring device for water tank type wire drawing machine

A water tank wire drawing machine and cable arrangement technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of low control precision, inability to achieve constant spacing of wires, and cutting wires that cannot meet the requirements of monocrystalline silicon wafer cutting, etc. Problems, to achieve the effect of improving accuracy and efficiency, avoiding improper wiring, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

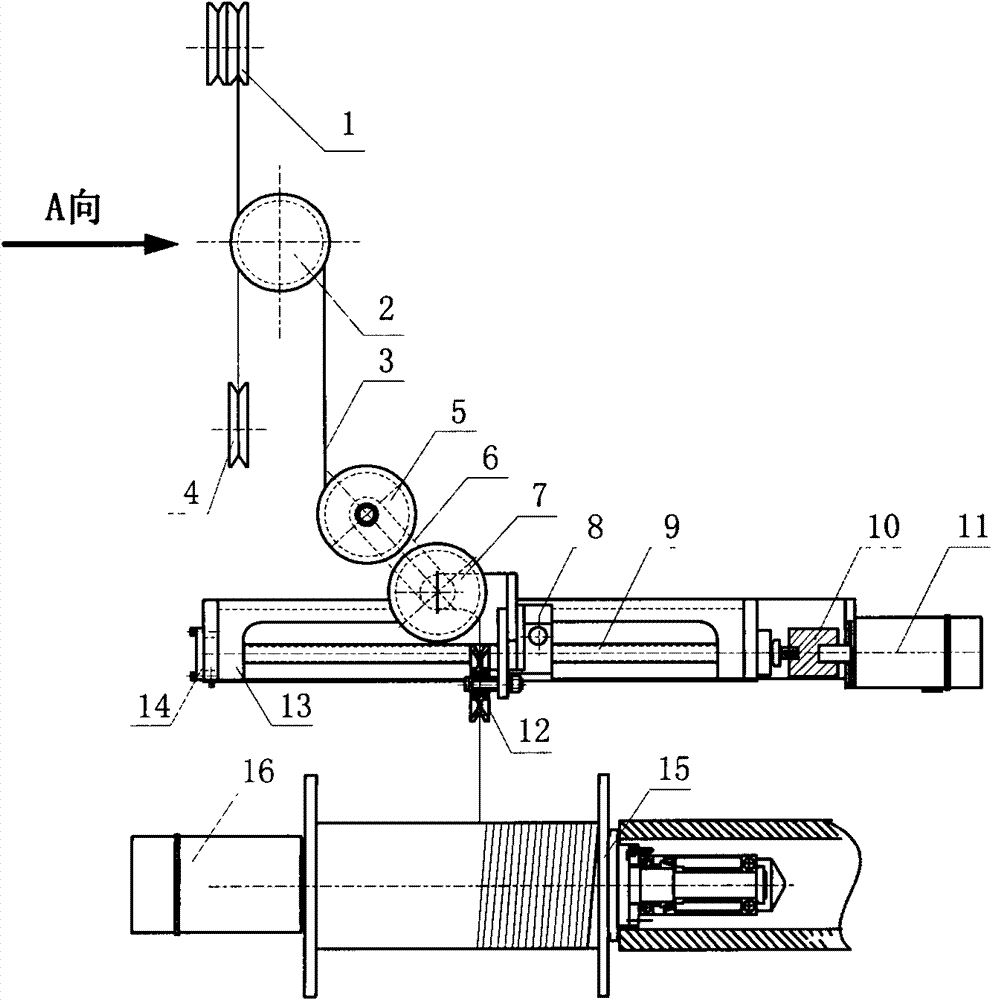

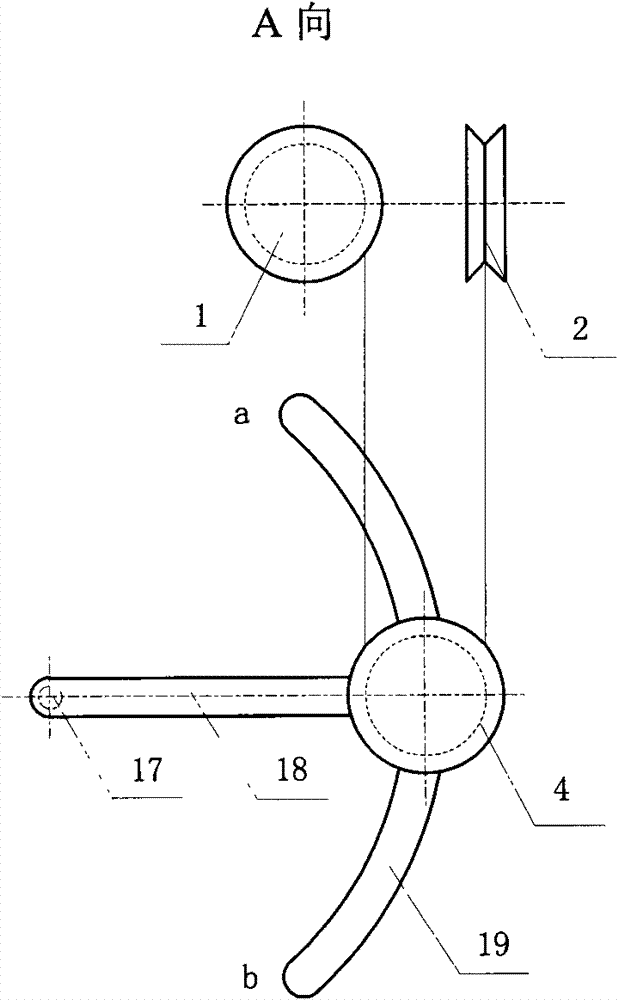

[0012] combine figure 1 and figure 2 , the self-compensating servo wire arranging device of the water tank wire drawing machine of the present invention includes a tension detection unit, a wire arranging branching device and a wire arranging collection device, wherein the tension detection unit consists of a first wire passing wheel 1, a second wire passing wheel 2, a tension Wire passing wheel 4, angle displacement sensor 17, tension rod 18 and guide groove 19 are formed, the first wire passing wheel 1, the second wire passing wheel 2 and the tension wire passing wheel 4 are installed on the wire drawing machine frame, wherein the first passing wire The wire wheel 1 and the tension wire wheel 4 are in the same plane, and the plane where the second wire wire wheel 2 is located is perpendicular to the plane where the tension wire wheel 4 is located and is tangent to the circumference of the tension wire wheel 4 to ensure that the wire passes through the first The wire thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com