Tangential distribution-type large-diameter multi-inlet gas distributor and application thereof in carbon dioxide adsorption tower

A gas distributor, carbon dioxide technology, applied in separation methods, dispersed particle separation, air quality improvement, etc., can solve the problems of uniformity in the gas distribution process, increase in pressure drop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical characteristics of the multi-inlet tangential distribution gas distributor based on the large-diameter carbon dioxide absorption tower of the present invention will be described in more detail below in conjunction with the accompanying drawings:

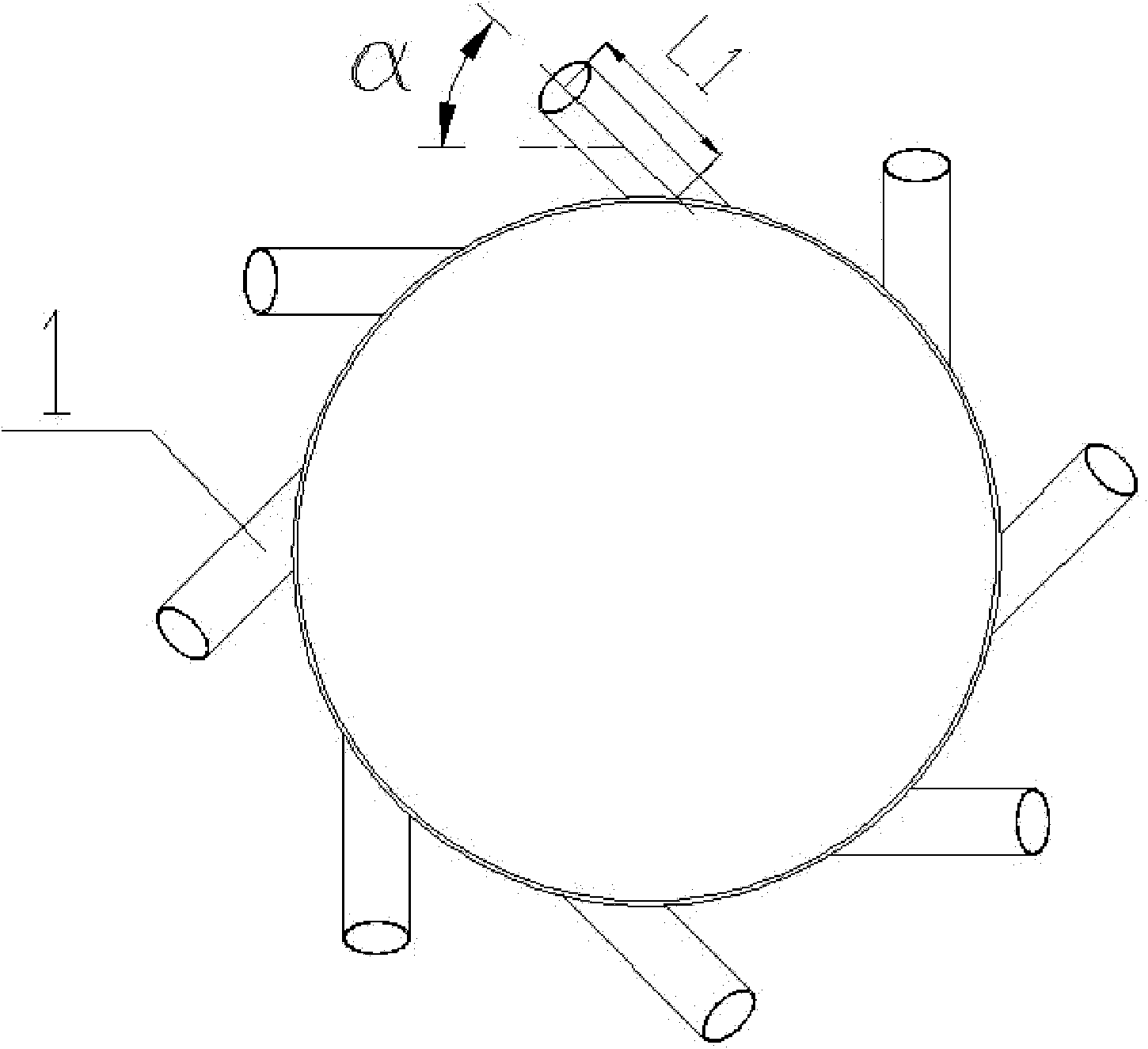

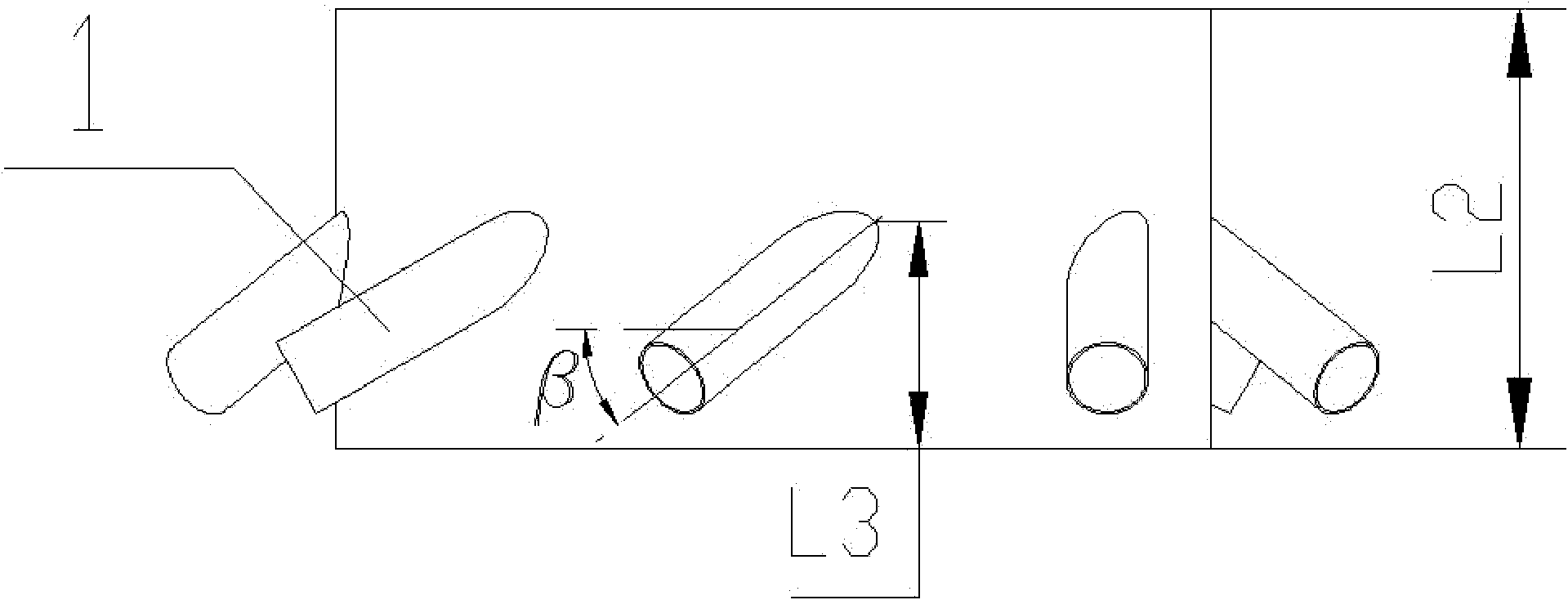

[0017] The multi-inlet tangentially distributed gas distributor based on the large-diameter absorption tower of the present invention is provided with a plurality of evenly distributed inlet pipes. It is aimed at large carbon dioxide absorption towers with a diameter greater than 1200mm.

[0018] The invention includes a plurality of air inlet pipes, which are evenly distributed on the outside of the distributor. The direction of its air inlet pipe mouth all is to open from bottom to top, can set up 6~12 air inlet pipes, evenly divides the circumference and distributes evenly.

[0019] The pipe diameter of its air intake pipe of the present invention is set to 40mm~60mm. The included angle α between the central...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com