Hull form intended for vessels provided with an air cavity

An air cavity, ship technology, used in ship hull, hull design, ship construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

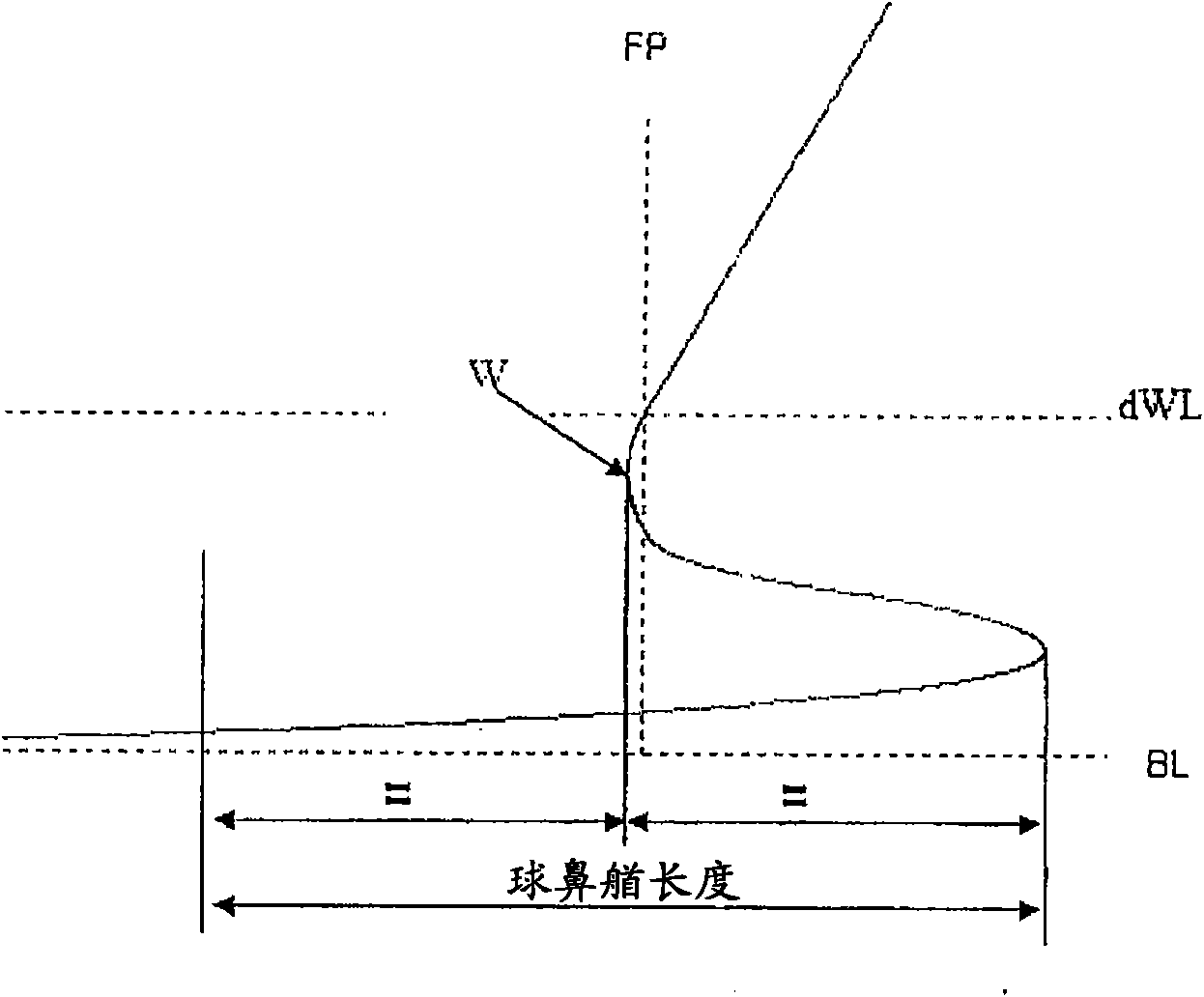

[0058] figure 1 The profile line is shown with the stem defined by the insertion. Baseline (BL) is the line parallel to dWL (design waterline) passing through the lowest point of the ship. The waist (W) of the bow is the most aft point of the bow at a position above the edge of the bow of the bow. In the figures, the bulb length is also defined. This limitation applies to the assumption that all transverse frames have a waist within this length. If this is not the case, the length is reduced from the stem edge of the bulb to the transverse frame, which is the last frame of the fore half of the hull with the waist.

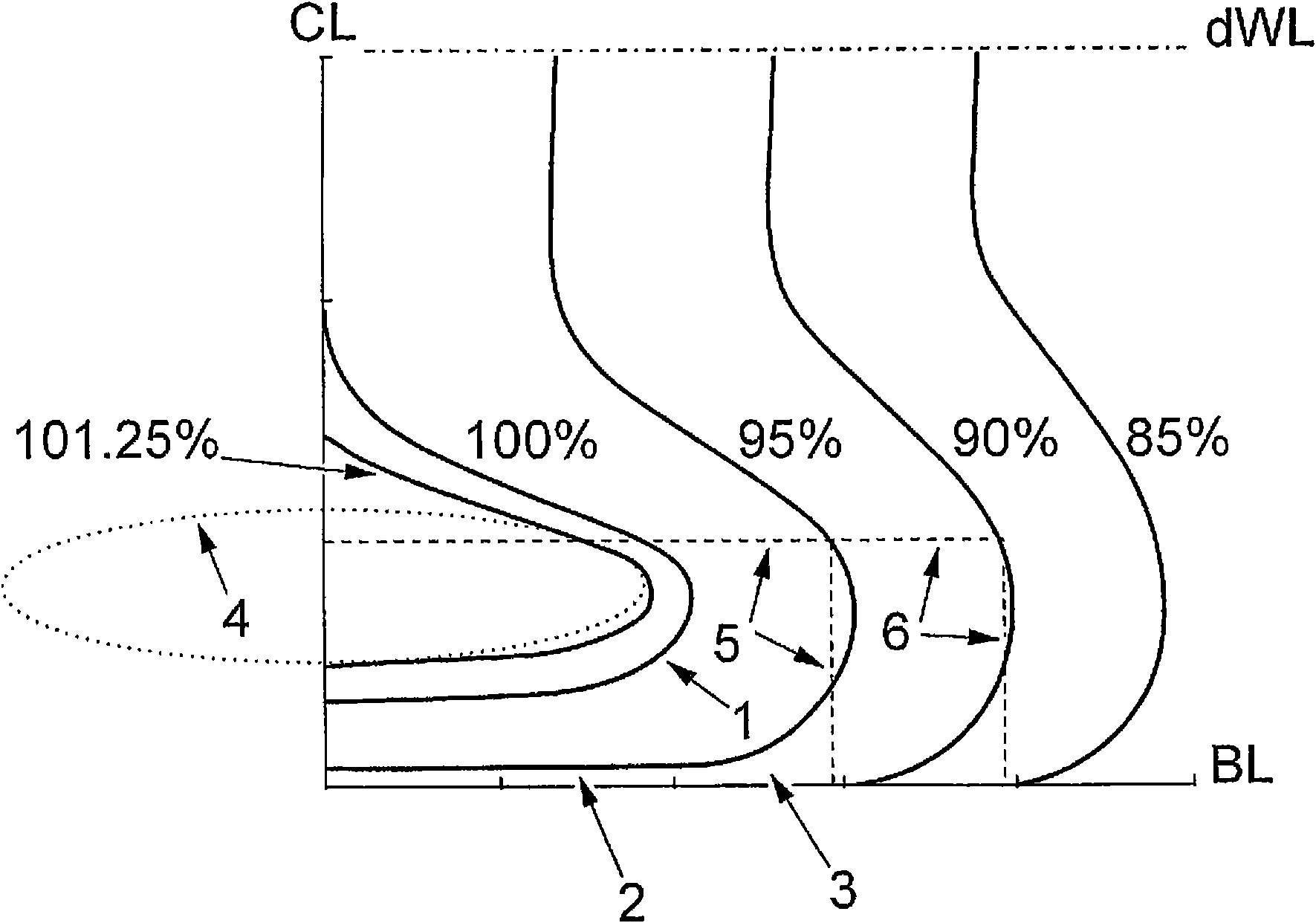

[0059] figure 2 An example of a profile line diagram showing the forward part of the hull up to dWL towards the bow. The frame shown corresponds to 85%, 90%, 95%, 100% and 101.25% of the length of the vertical line. 50% corresponds to amidships, and 100% corresponds to the frame of the forward perpendicular (FP). 101.25% of the length of the perpendicular c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com