Inter-cooling integral volute

A volute and cooler technology, which is applied in the direction of machines/engines, internal combustion piston engines, mechanical equipment, etc., can solve the problems of inability to install intercoolers, etc., and achieve the effects of simple structure, increased power, and reduced structural size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

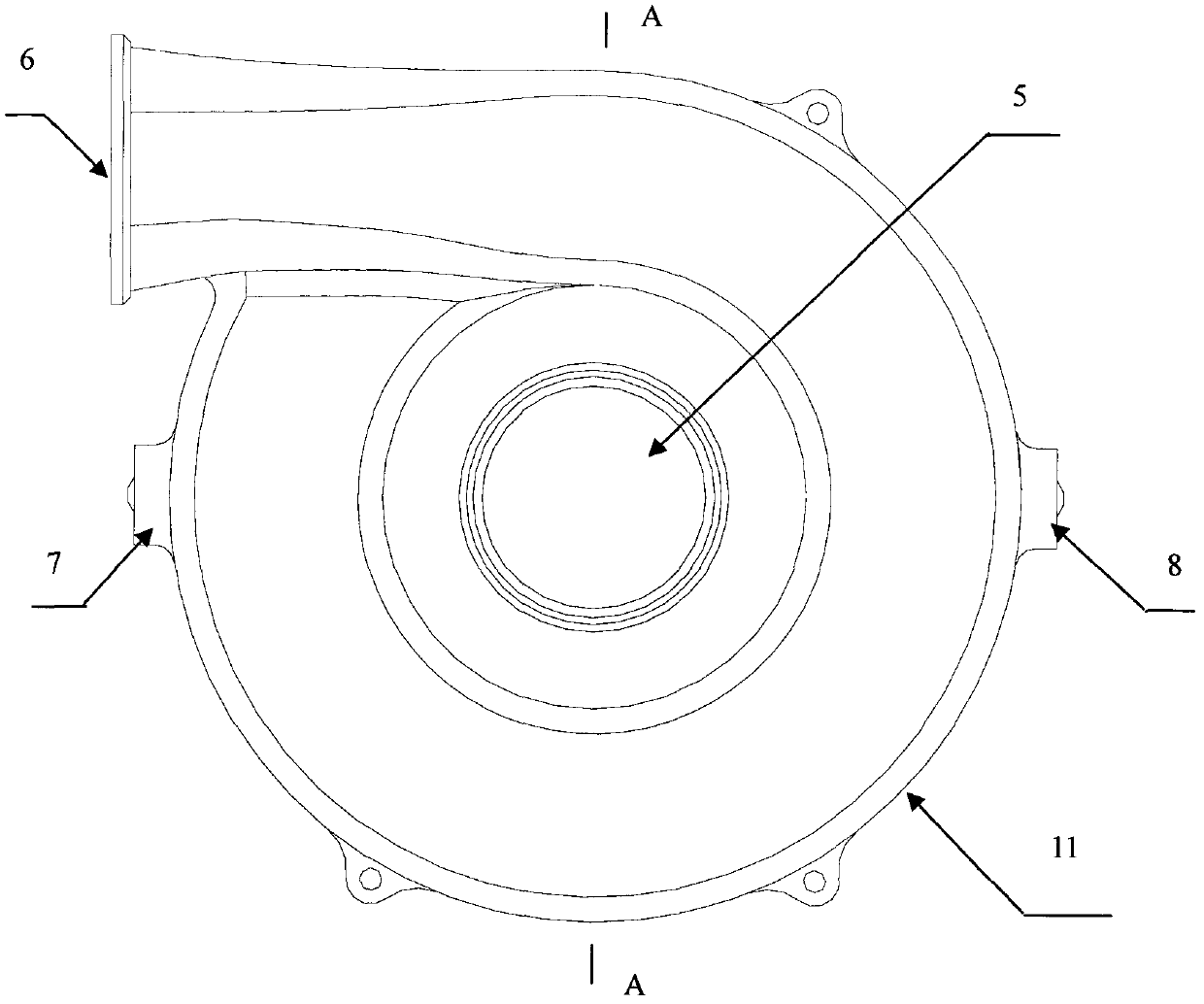

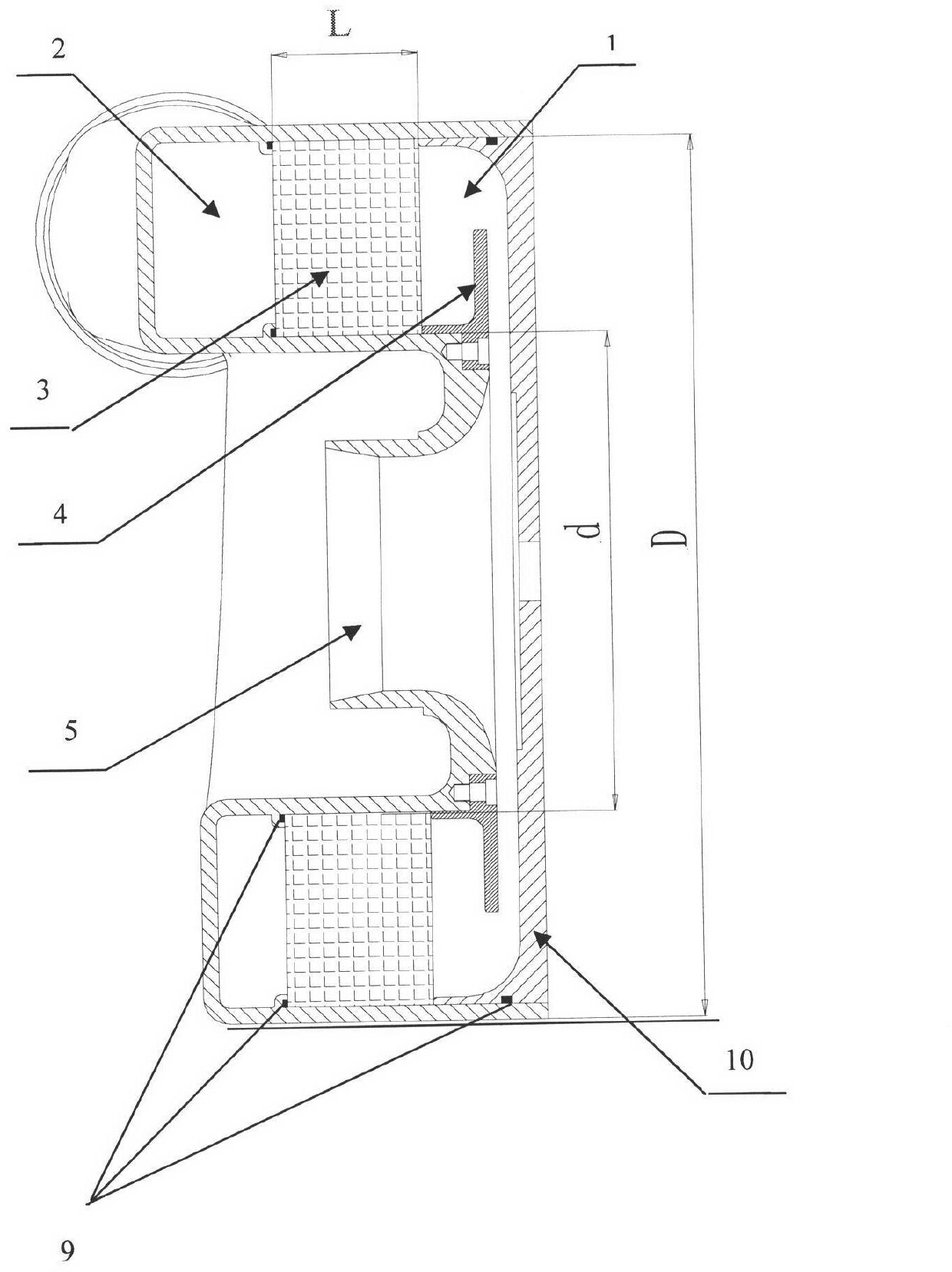

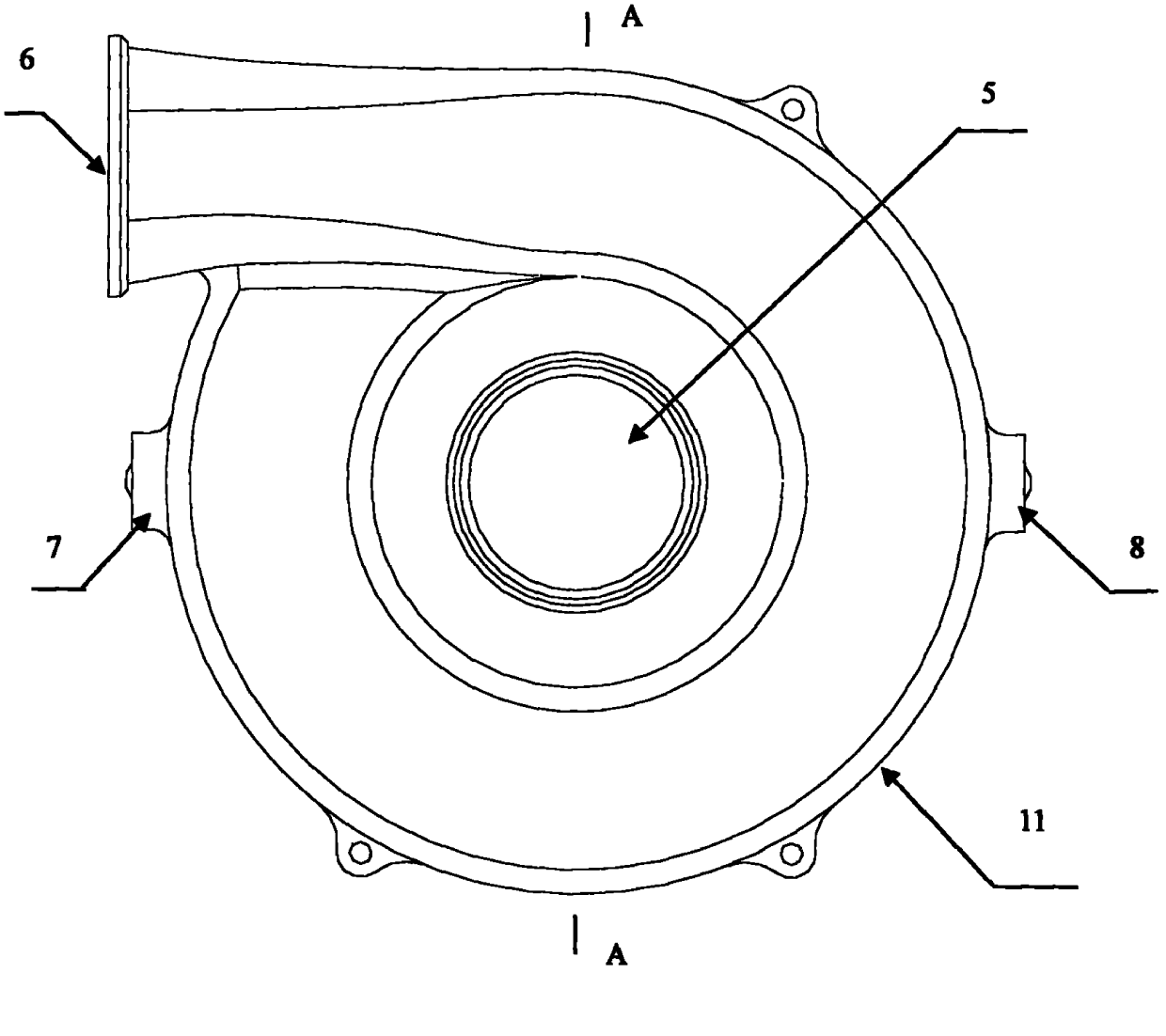

[0008] An intercooler integrated volute, which includes an airflow channel 1 before the intercooler, an airflow channel 2 after the intercooler, an annular intercooler 3, a diffuser plate 4, an airflow inlet 5, an airflow outlet 6, a cooling water inlet 7, a cooling The water outlet 8, the sealing rubber ring 9, the back plate 10 and the volute 11, the volute 11 is provided with an air passage 1 before intercooling, an air passage 2 after intercooling, an air passage 1 before intercooling and an air passage after intercooling 2 is provided with an annular intercooler 3, the annular intercooler 3 is fixed in the housing 11 through the diffuser plate 4 and the back plate 10, the annular intercooler 3 and the volute 11 are sealed by a sealing rubber ring 9, and the volute Shell 11 is provided with airflow inlet 5, airflow outlet 6, cooling water inlet 7, cooling water outlet 8, cooling water inlet 7, cooling water outlet 8 are arranged at 180°, cooling water inlet 7, cooling water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com