Automatic air gun for measuring oil well liquid level

A liquid level measurement and air gun technology, applied in measurement, wellbore/well components, earth-moving drilling, etc., can solve the problems of complex structure, sound pulse, self-adaptation, etc., to achieve simple airway connection, good sealing performance, structural compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

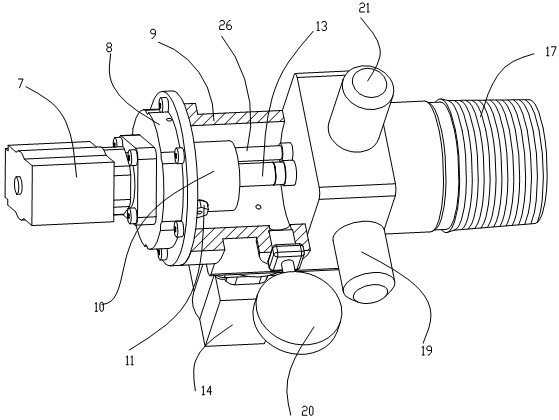

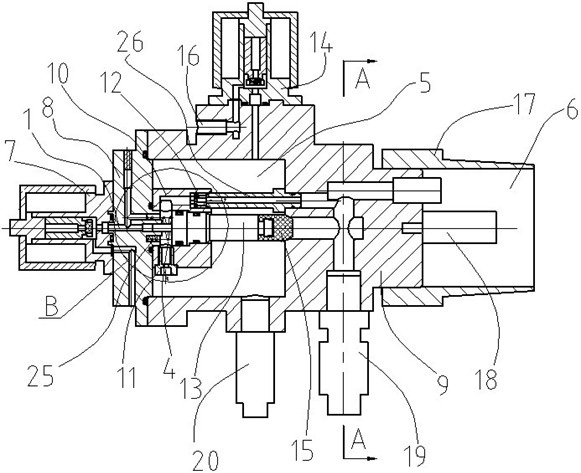

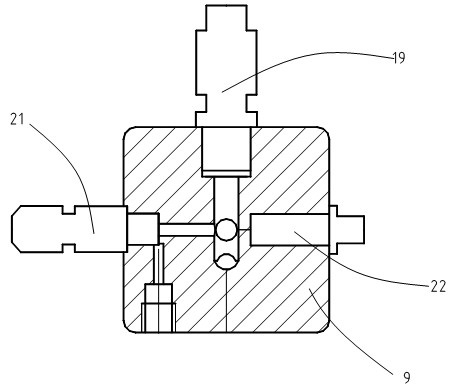

[0030] According to the principles of the cartridge valve and the differential pressure area method, the present invention adopts a four-step stepped design for the main valve stem of an ordinary air gun, and introduces two air source pressures at the force-bearing end of the air source, so that one end of the air gun is both affected by the internal pressure. The gas pressure of the gas source is also affected by the gas pressure of the external gas source, so that no matter whether the internal gas source is a high-pressure gas source or the external gas source is a high-pressure gas source, there is a high-pressure gas source as the driving gas source for the main valve stem, and The other end of the main valve stem introduces high-pressure gas through the damping channel, and adopts the differential pressure area method, so that the force bearing area of the main valve stem control chamber end is larger than the force bearing area of the gas source end, so the total forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com