Thin-wall soil retaining brick die

A technology of retaining bricks and thin walls, which is applied in construction, infrastructure engineering, etc., can solve problems such as rework, collapse or deformation, and construction troubles, and achieve the effects of increasing bending resistance, ensuring progress, and saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] 1. Structure introduction

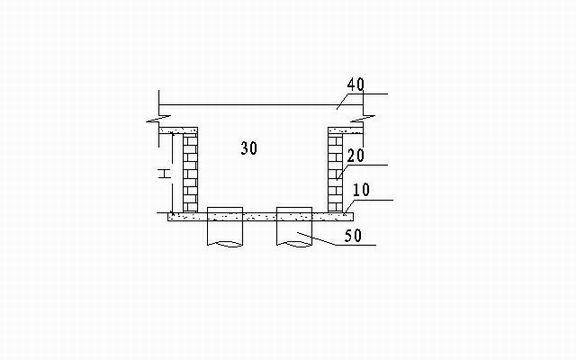

[0024] figure 1 It is a construction schematic diagram of the thin-wall earth retaining brick form of the present invention. The mark 30 refers to the cap, the mark 10 refers to the cushion layer, and the mark 50 refers to the pile. On the platform 30 is a bottom plate 40 . Cap 30, cushion 10 and pile 50 are all under the ground. In order to ensure the construction of the platform cap 30, the present invention provides a thin-wall earth retaining brick form 20.

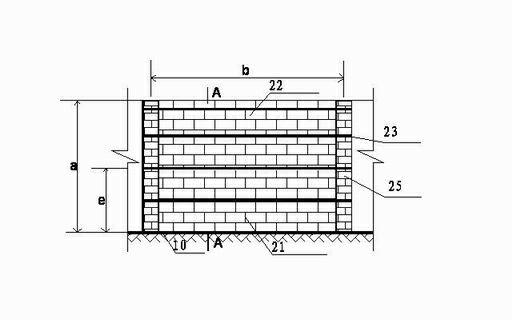

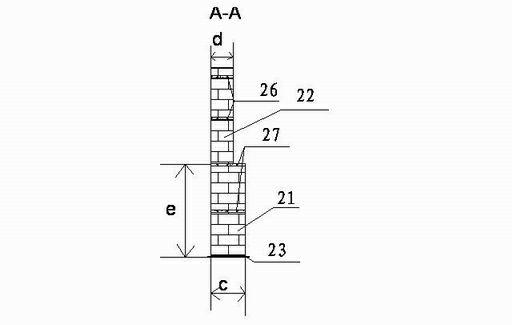

[0025] figure 2 , image 3 It is a schematic diagram of an embodiment of the thin-wall retaining brick mold of the present invention. in figure 2 is the front view (schematic diagram looking towards the membrane surface), image 3 for figure 2 A-A view of the.

[0026] like figure 2 , image 3 As shown, the thin-wall retaining brick mold is made of bricks in the prior art, and has a certain height a, thickness and length, and the height of the thin-wall earth retainin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com