Sludge treatment process

A sludge treatment and sludge technology, which is applied in dewatering/drying/concentrating sludge treatment, sewage/sludge fertilizer, cement production, etc., can solve the problems of excessive heavy metal content in grains and vegetables, human health hazards, and high operating costs. , to achieve the effect of no secondary pollution, no pollution to the atmospheric environment, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

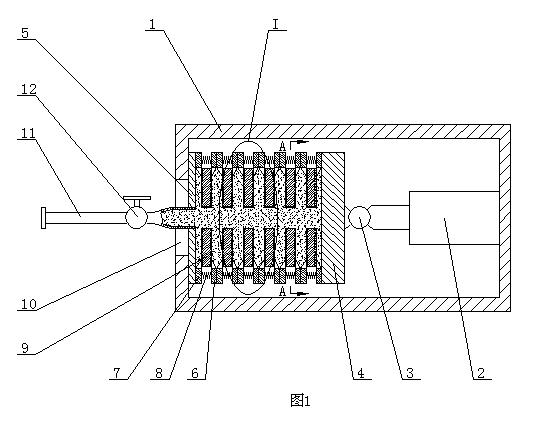

[0017] The plate and frame filter press described in the process of the present invention includes a housing 1, a pressure cylinder 2 is installed in the housing 1, the pressure cylinder 2 is connected with the pressure plate 4 through the shaft 3, and multiple pieces are installed between the pressure plate 4 and the fixed plate 5 Filter plate 9, filter membrane 14 is set on the filter plate 9, through hole 15 is offered in the middle part of filter plate 9, filter frame is installed on the periphery of filter plate 9, spring 8 is installed between the filter frames, and spring 8 is evenly distributed around the filter frame. The feed pipe 11 of the plate and frame filter press enters the cavity of the filter press through the through hole 10 on the shell 1, and the feed control valve 12 is installed on the feed pipe 11, and the sludge is pumped into the filter press through the feed pipe 11 Filter and squeeze the sludge until the water content of the sludge is below 40%.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com