Chassis device of automatic lifting vehicle

An automatic lifting and chassis technology, which is applied to vehicle components, transportation and packaging, elastic suspension, etc., can solve the problems of no automatic lifting chassis device, inability to carry out work, inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

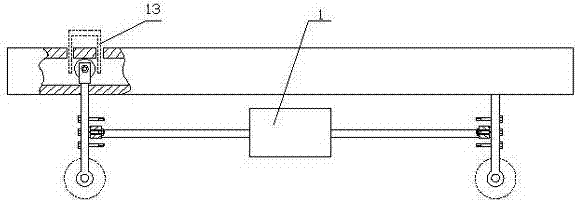

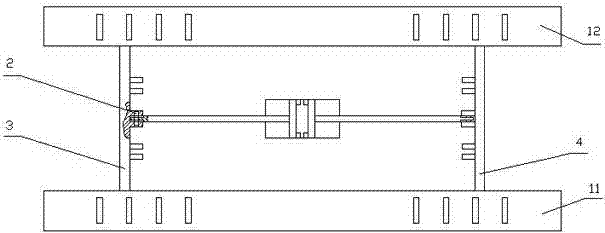

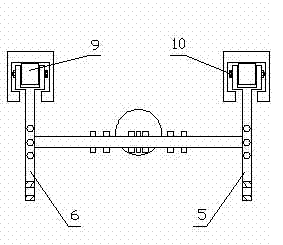

[0017] Such as figure 1 As shown, the automatic lifting vehicle chassis device includes double-rod hydraulic cylinder 1, pin 2, front axle 3, rear axle 4, No. 1 front wheel bracket 5, No. 2 front wheel bracket 6, No. 3 rear wheel bracket 7, No. 4 Rear wheel support 8, roller 9, stud and gasket 10 thereof, No. 1 guide rail 11, No. 2 guide rail 12, wedging device 13. The hydraulic drive system is connected with the center of gravity balance adjustment system on the horizontal plane: the double-rod connecting platform of the hydraulic cylinder on the front axle 3 and one end of the double-rod hydraulic cylinder 1 are fastened by the pin 2. 3. The center line of the hole on the double-rod connecting platform of the hydraulic cylinder coincides. The double-rod connecting platform of the hydraulic cylinder on the rear axle 4 and the other end of the double-rod hydraulic cylinder 1 are fastened by the pin 2. When installing, the center of the hole at this end of the double-rod hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com