Biomembrane water purifying gate for aquaculture and in-situ water processing method of biomembrane water purifying gate

An in-situ water treatment and aquaculture technology, applied in biological water/sewage treatment, sustainable biological treatment, water/sludge/sewage treatment, etc. Solve the problems of many facilities and high operating costs, and achieve the effects of good growth, saving land and a large amount of investment costs, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

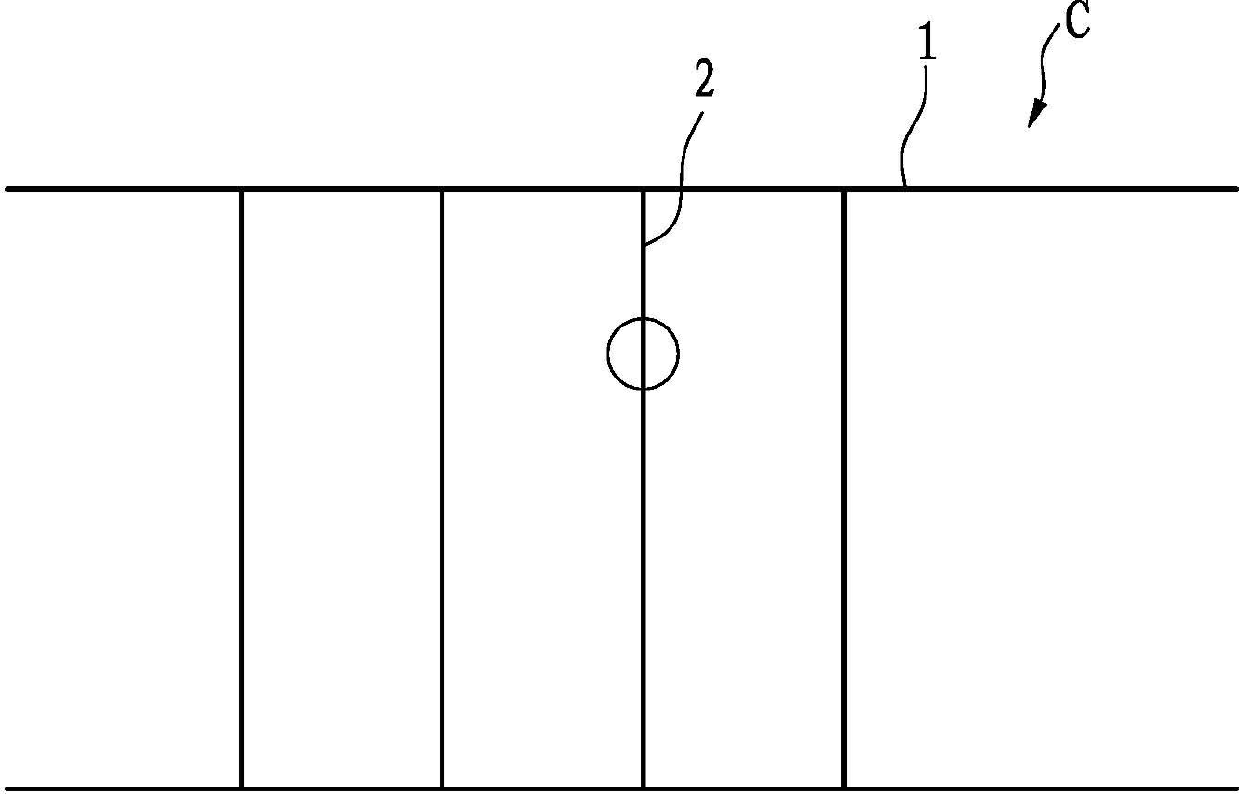

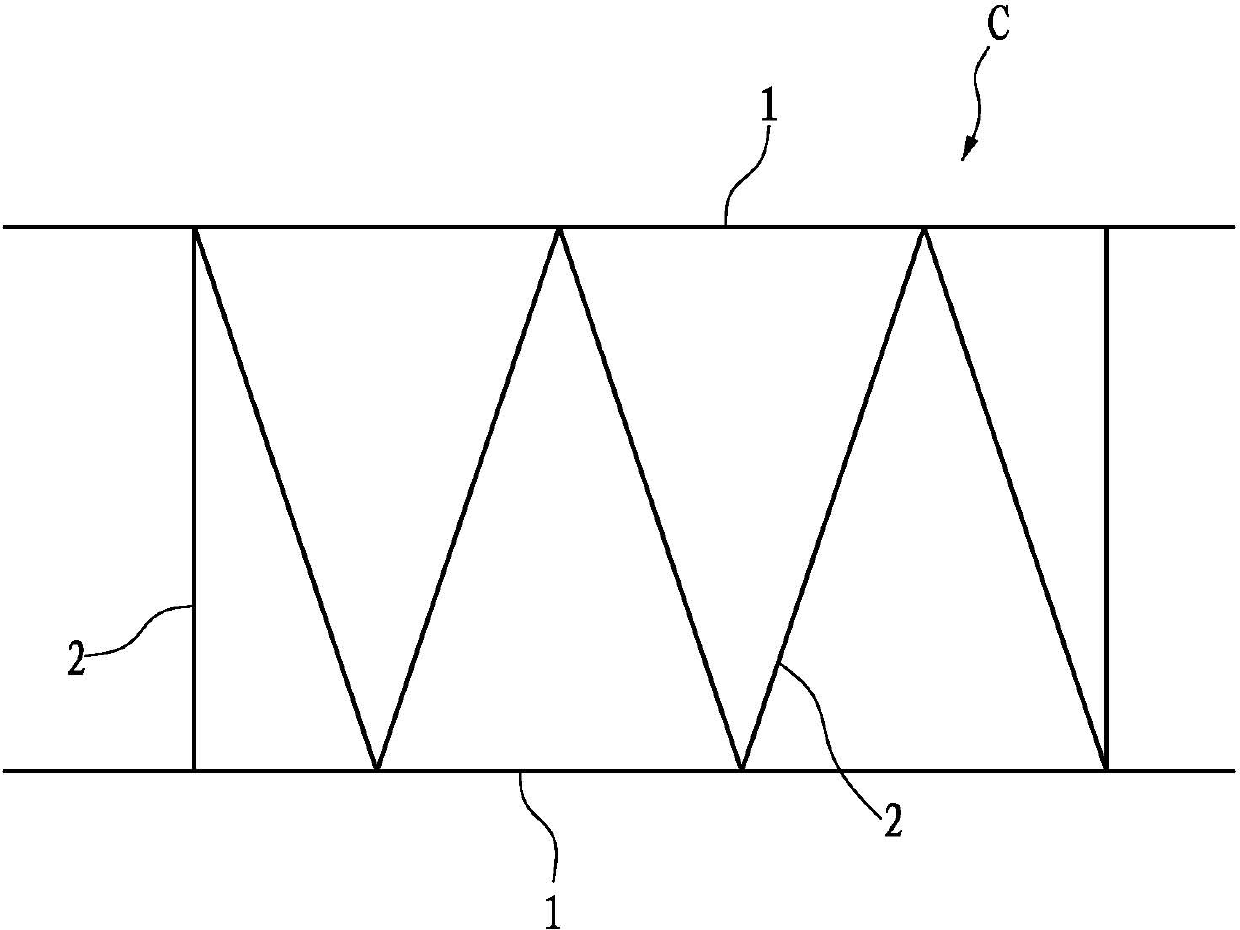

[0028] Such as figure 1 , 2 and cooperate image 3 , 4 As shown, the present invention discloses a special biofilm water purification grid for aquaculture and a method for in-situ water treatment of the biofilm water purification grid. The linear three-dimensional elastic filler 2 is formed by winding a number of radial elastic wires elastic wires 22 on a base line 21. The three-dimensional elastic filler 2 constitutes the carrier of the microbial community, thereby forming a biofilm.

[0029] Such as figure 1 In the biofilm water purification grid C structure shown, several linear three-dimensional elastic fillers 2 are in a vertical state with two nylon ropes 1; and as figure 2 In the biofilm water purification grid C structure shown, the linear three-dimensional elastic packing 2 tied between two nylon ropes 1 and arranged obliquely can also constitute the biofilm water purification grid C.

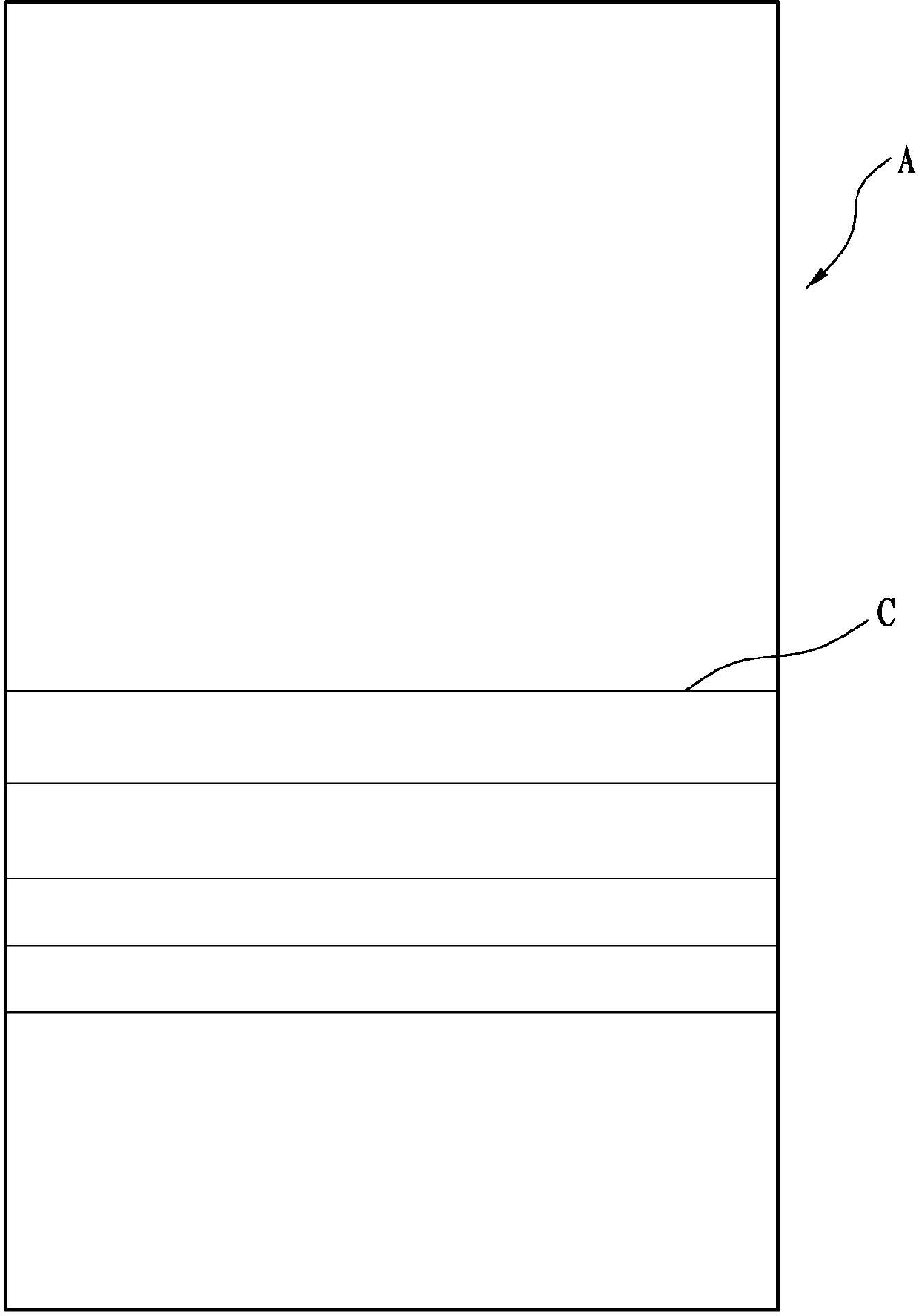

[0030] combine image 3 , 4 Shown, the method that biofilm water purificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com