Electric heating film having anti-leakage function

An electric heating film, anti-leakage technology, applied in electric heating devices, ohmic resistance heating, ohmic resistance heating parts and other directions, can solve the problems of low tear resistance, excessive leakage current, affecting the service life of products, etc. The effect of tearing strength, improving thermal conversion power, and improving installation power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

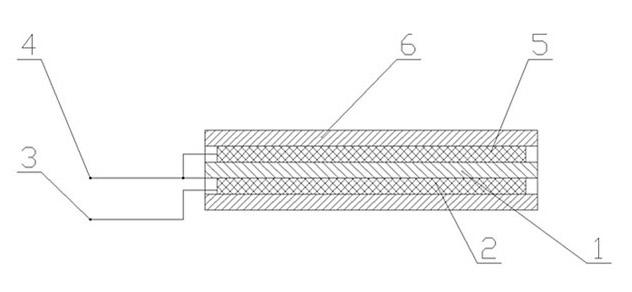

[0018] Such as figure 1 Shown: It has the same upper and lower layers of insulating film 1 as the prior art, and a conductive heating layer 2 is sandwiched between the two layers of insulating film 1. The conductive heating layer 2 is connected to the live wire electrode 3 and the neutral wire electrode 4, and is connected to the current wire electrode 3. The difference between existing technologies is that the upper insulating film 1 is covered with a second conductive layer 5 connected to the neutral electrode 4 , and the second conductive layer 5 is covered with a second insulating layer 6 . The second conductive layer 5 and the insulating film 1 can be fixed as a whole, or can be a split structure. The materials and structures of the second conductive layer 5 and the second insulating layer 6 can be the same as those of the conductive heating layer 2 and the insulating film 1 of the prior art. , it is also possible to add a layer of insulating film between the insulating f...

Embodiment 2

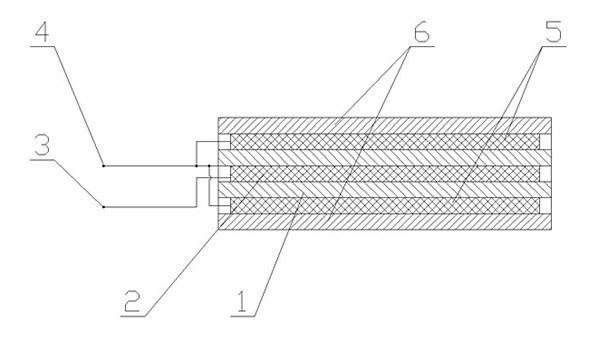

[0022] Such as image 3 Shown: It has the same upper and lower layers of insulating film 1 as the prior art, and a conductive heating layer 2 is sandwiched between the two layers of insulating film 1. The conductive heating layer 2 is connected to the live wire electrode 3 and the neutral wire electrode 4, and is connected to the current wire electrode 3. The difference in existing technology is that the second conductive layer 5 connected to the neutral electrode 4 is covered on the upper surface of the upper insulating film 1 and the lower surface of the upper insulating film 1, and the second conductive layer 5 is coated on the outside. There is a second insulating layer 6 . The second conductive layer 5 and the insulating film 1 can be fixed as a whole, or can be a split structure. The materials and structures of the second conductive layer 5 and the second insulating layer 6 can be the same as those of the conductive heating layer 2 and the insulating film 1 of the prior ...

Embodiment 3

[0024] Such as Figure 4 Shown: the basic structure is the same as that of embodiment 1, the difference from embodiment 1 is that a layer of third conductive layer 7 connected to the ground is covered on the second insulating layer 6, and the outside of the third conductive layer 7 is covered with a third insulating layer8. Similarly, the third conductive layer 7 and the second insulating layer 6 can be fixed as a whole, or can be a split structure. The materials and structures of the third conductive layer 7 and the third insulating layer 8 can be the same as those of the prior art conductive heating Layer 2 and insulating film 1 may also add a layer of insulating film between the second insulating layer 6 and the third conductive layer 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com