Double-cylinder line-up fuel injection pump for diesel engine

A split-type, diesel engine technology, applied in the direction of fuel injection pumps, mechanical equipment, engine components, etc., can solve the problems of rising fuel pressure in the plunger cavity, difficulty in controlling the lift of the oil delivery valve, and reduced circulating oil supply, and achieves improved Injection pressure, facilitate the uniformity of oil supply, eliminate the effect of secondary injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

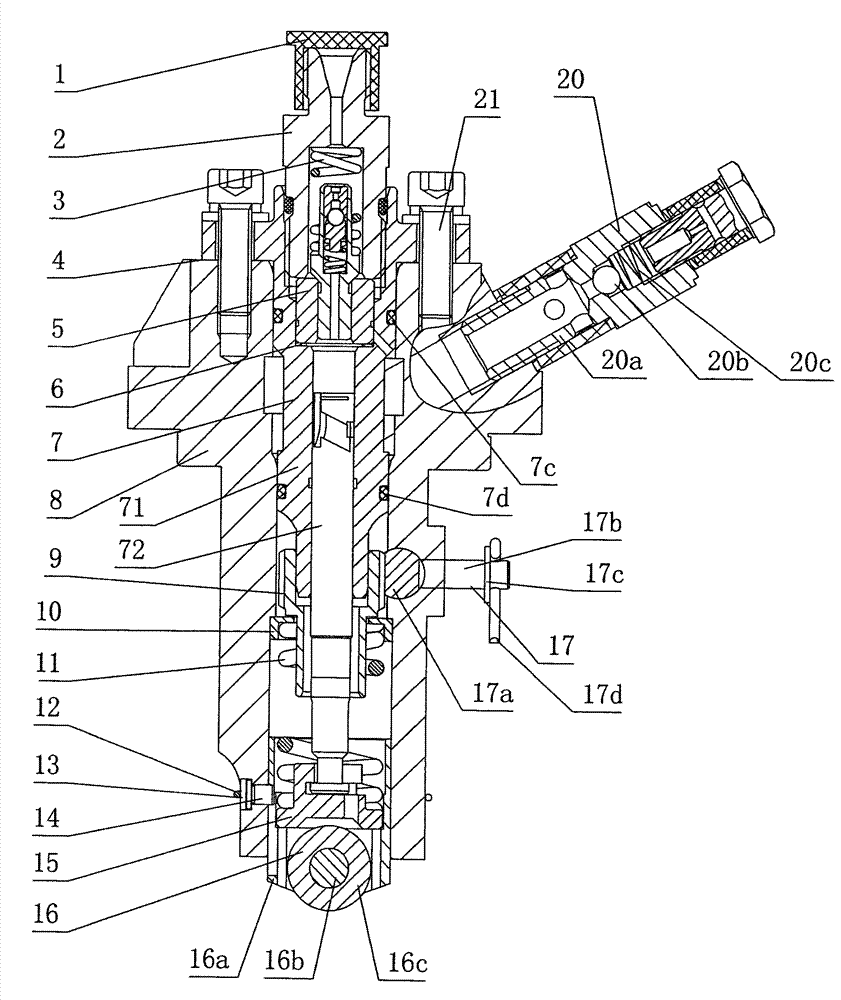

[0021] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

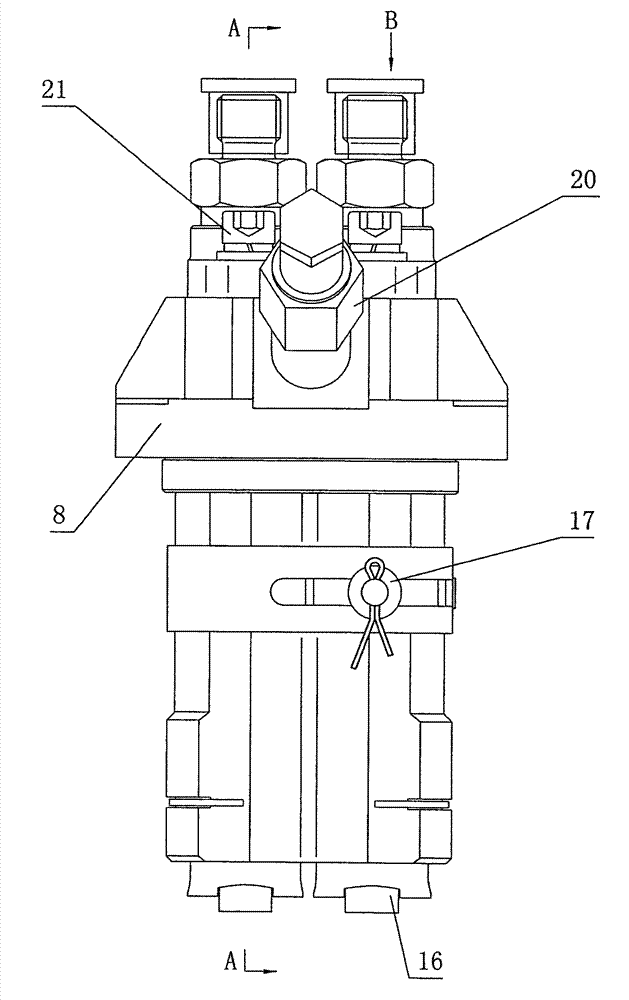

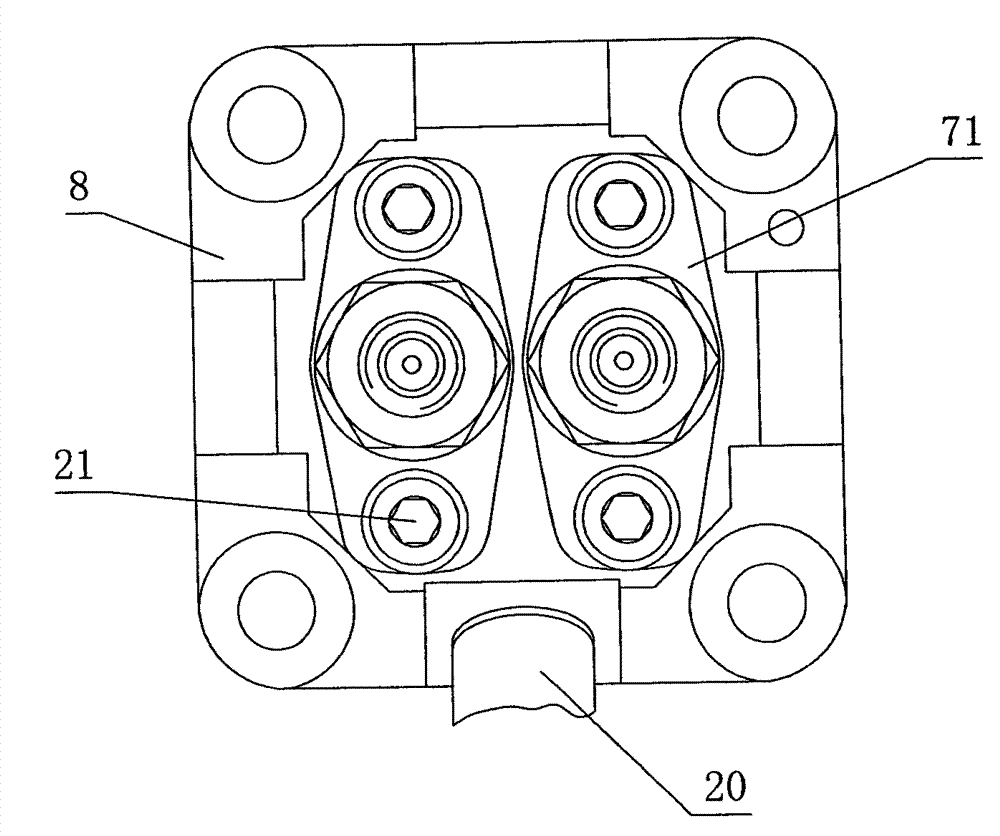

[0022] Figure 1 to Figure 6 Shown is the structural representation of the present invention.

[0023] The reference signs are: Oil outlet valve protective cap 1, Oil outlet valve tight seat 2, Oil outlet valve spring 3, Gasket 4, Isobaric oil outlet valve assembly 5, Oil outlet valve core 5a, Shock valve 5b, steel Ball 5c, spring seat 5d, spring 5e, oil outlet valve seat 5f, high pressure sealing washer 6, plunger coupler 7, plunger sleeve 71, flange 71a, waist groove 71b, plunger 72, O-ring 7c, O-shaped sealing ring 7d, housing 8, adjusting tooth sleeve 9, spring support body 10, plunger spring 11, cover 12, steel wire retaining ring 13, positioning pin 14, spring lower seat 15, holding body assembly 16 , Standing body 16a, roller pin 16b, roller 16c, adjusting gear rod assembly 17, adjusting gear rod 17a, positioning pin 17b, flat washer 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com