Preparation method of superparamagnetism easily-degradable oil stain absorption material and product obtained by method

A superparamagnetic and easily degradable technology, applied in the direction of inorganic material magnetism, chemical instruments and methods, and other chemical processes, to achieve the effects of variable volume, high recovery rate of waste oil, and enhanced ability to absorb oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

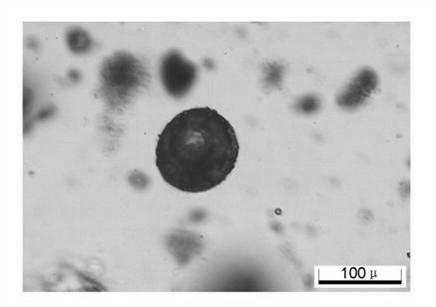

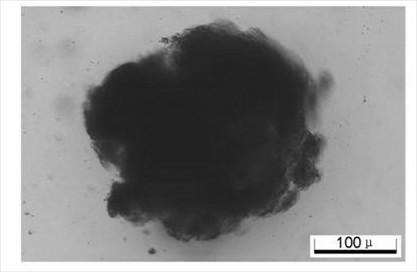

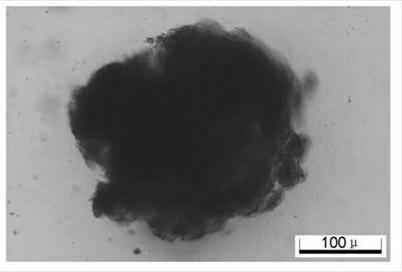

Image

Examples

Embodiment 1

[0018] (a) Add 2g of glacial acetic acid to 18g of pure water to prepare a 1% acetic acid solution by mass. Accurately weigh 0.6g of chitosan, and add chitosan to 19.4g of 1% acetic acid solution by mass percentage under constant temperature stirring at 80°C, and keep the chitosan-acetic acid-water solution at 80°C In a constant temperature stirring environment.

[0019] (b) Hydrophilic superparamagnetic Fe stored at a low temperature of 3–5°C 3 o 4 The nanoparticles are taken out from the refrigerator, the magnets absorb the nanoparticles, and the Fe 3 o 4 The tetramethylammonium hydroxide (TMA) liquid with a molar concentration of 1mol / L is poured out. Weigh 0.6g of Fe 3 o 4 Add it into the chitosan-acetic acid-water solution under stirring state, and then vibrate ultrasonically for 2~3 minutes.

[0020] (c) Take pure water equal to the volume of the solution in (b), keep the temperature in an oil bath at 80°C for 10-15 minutes, dissolve 1 g of sodium stearate in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com