Die cutting machine

A die-cutting machine and die-cutting technology, applied in the direction of metal processing, etc., can solve the problems of low die-cutting precision, high labor cost, high labor intensity, etc., to reduce purchase and maintenance costs, reduce personnel wage costs, and simple and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

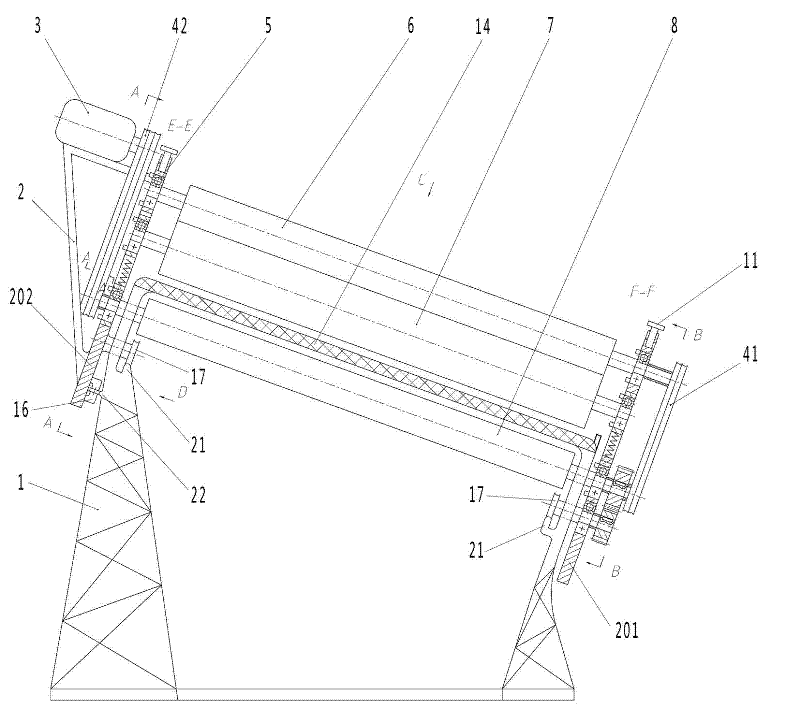

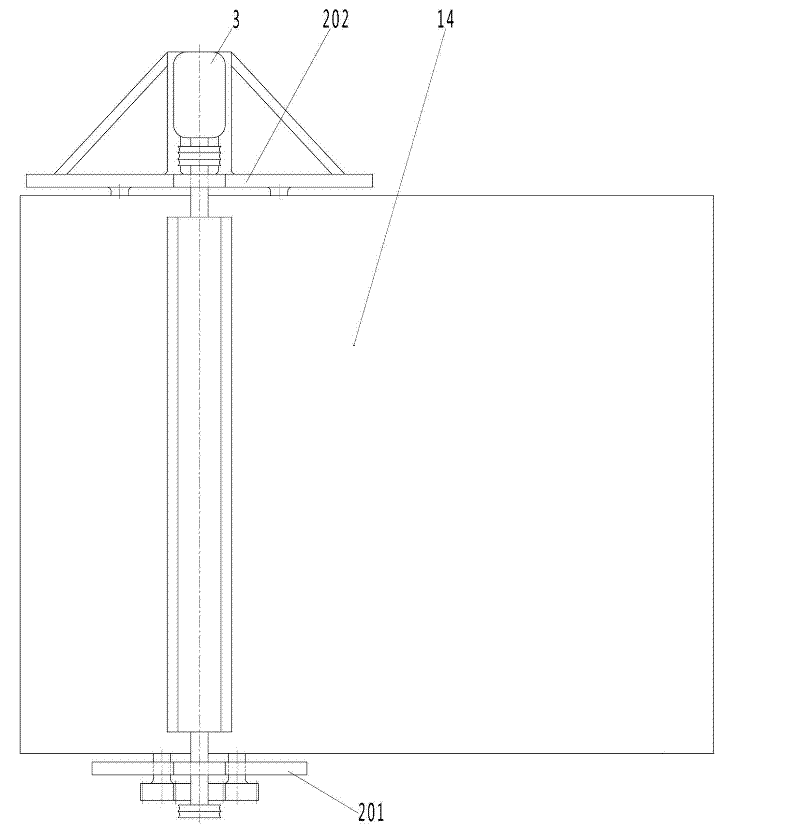

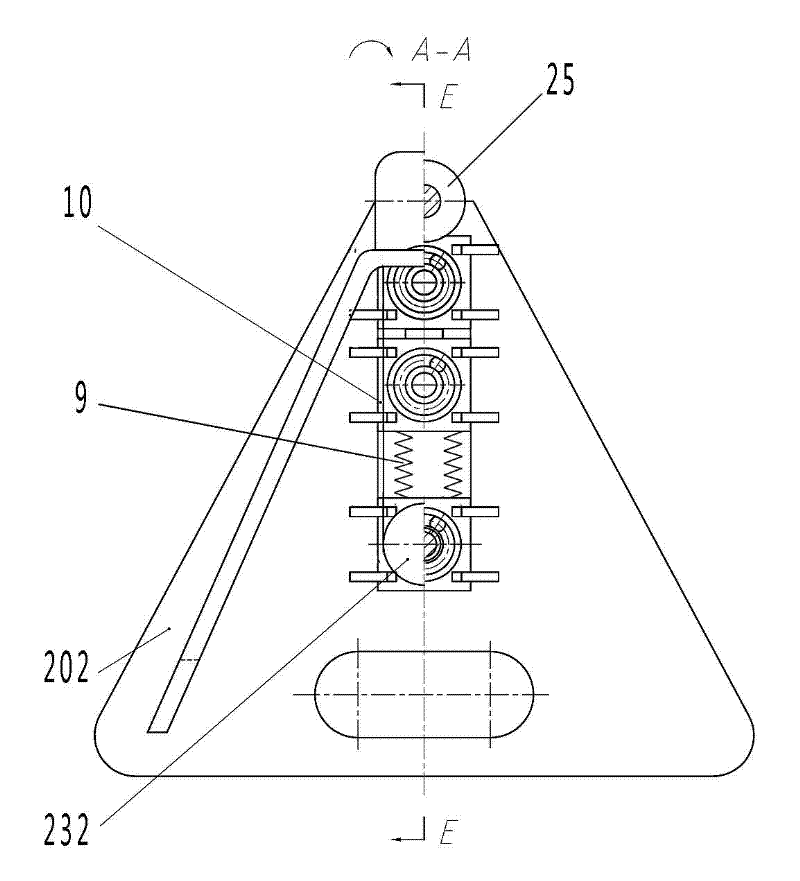

[0031] The present invention includes a frame 1, a motor assembly, a die-cutting platen 14 and a die-cutting assembly.

[0032] For the convenience of description and reference (but not limited thereto), the sliding direction of the die-cutting assembly of the present invention is defined as "left" and "right", and the remaining two sides are defined as "near end" and "far end", wherein the approaching operation The operator's end is called "near end", and the end away from the operator is called "far end".

[0033] Such as figure 1 As shown, the frame 1 is a similar cuboid frame, and the die-cutting table 14 is fixedly installed on the frame 1 . A horizontal guide rail 21 is welded on each side of the inner side of the proximal end and the inner side of the far end of the frame 1 to support the die-cutting assembly.

[0034] Such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com