Fuel vapour storage

A fuel vapor and fuel tank technology, which is applied in the directions of adding non-fuel substances to fuel, combining with the fuel supply of internal combustion engines, charging systems, etc., can solve problems such as the exhaustion of fuel vapor capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

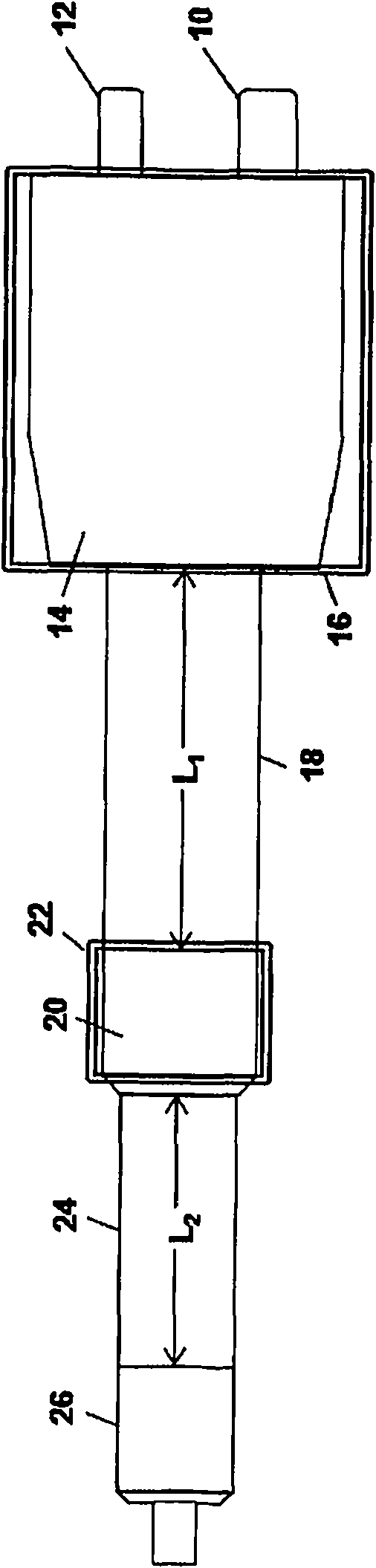

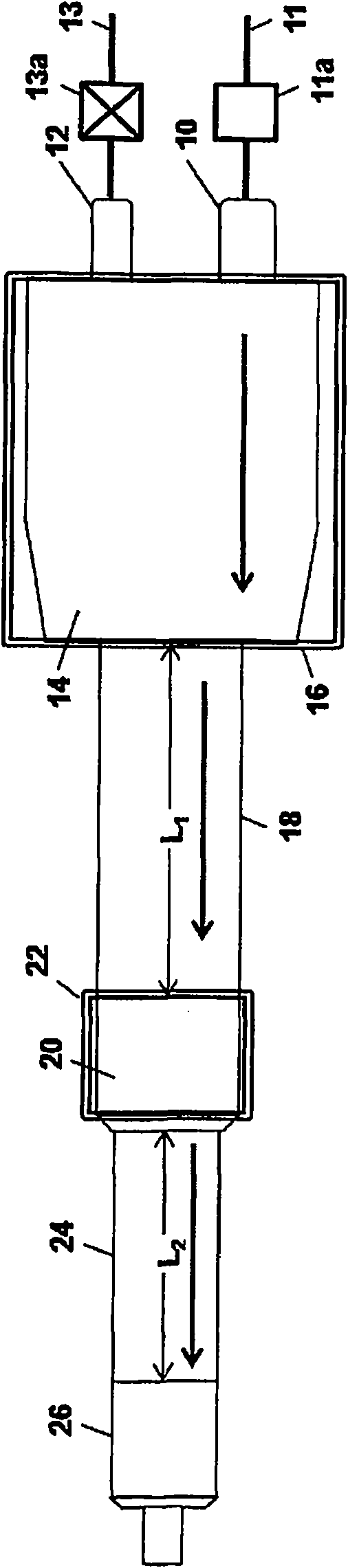

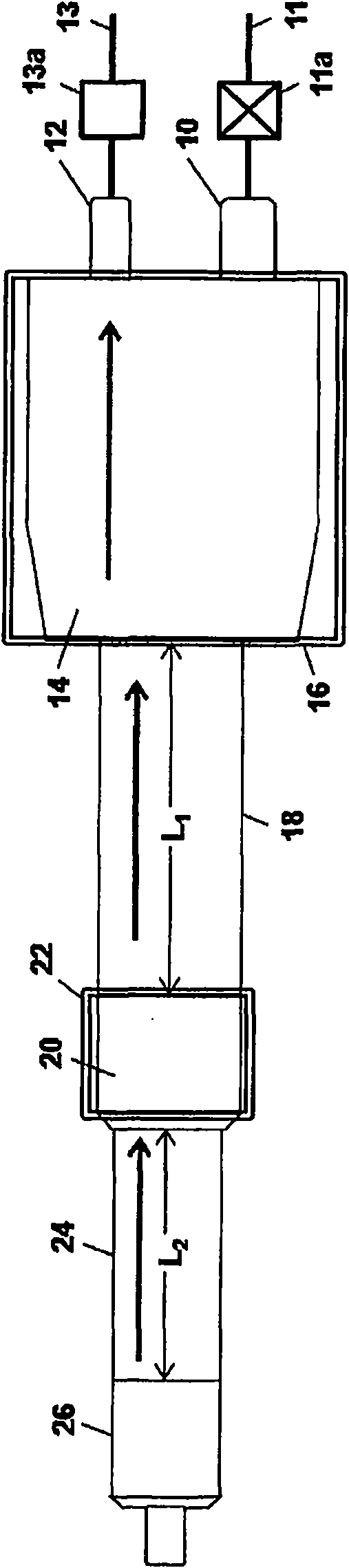

[0025] Embodiments of the present invention provide an absorber tank for controlling emissions from an automotive fuel tank, the tank comprising first and second adsorbent beds and flow channels configured to transfer the The beds are connected in series, wherein the flow path includes a heat exchanger configured to exchange heat between the first adsorbent bed and ambient air, the heat exchanger being internally partitioned to Air is directed in a serpentine path on the outer wall of an adsorbent bed.

[0026] The first adsorbent bed may be configured for end-to-end flow and may have polygonal, elliptical, or cylindrical side walls, the heat exchanger configured to cover more than 50% of the area of the side walls, In a further embodiment more than 75% of the area of the sidewall is covered, and in a still further embodiment more than 90% of the area of the sidewall is covered. The internal partition of the heat exchanger may be configured so that the gas makes two, fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com