Engine device

An engine and exhaust gas purification device technology, applied in engine components, combustion engines, machines/engines, etc., can solve the problem of exhaust gas temperature drop in exhaust gas purification devices, and achieve the effect of improving versatility and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

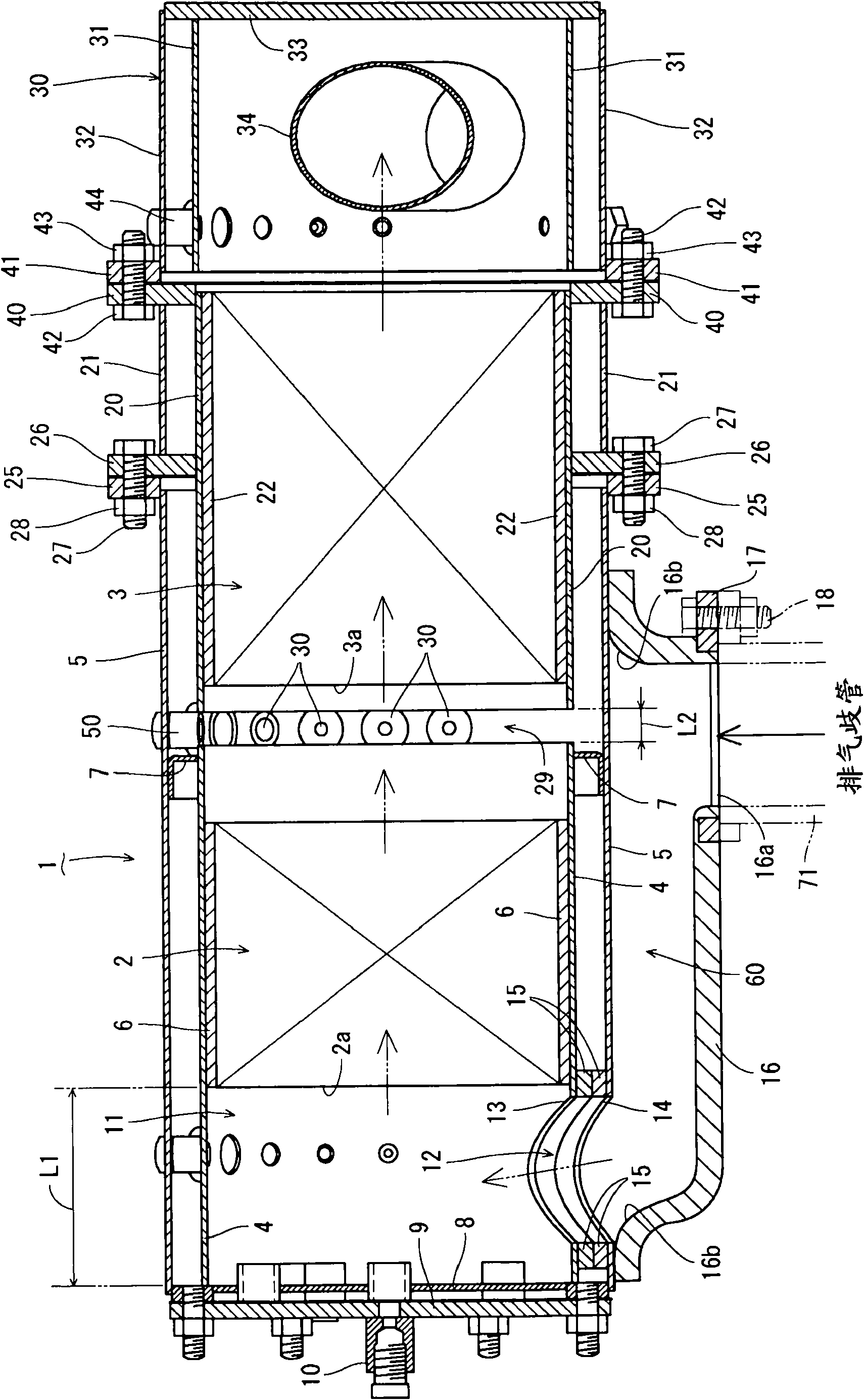

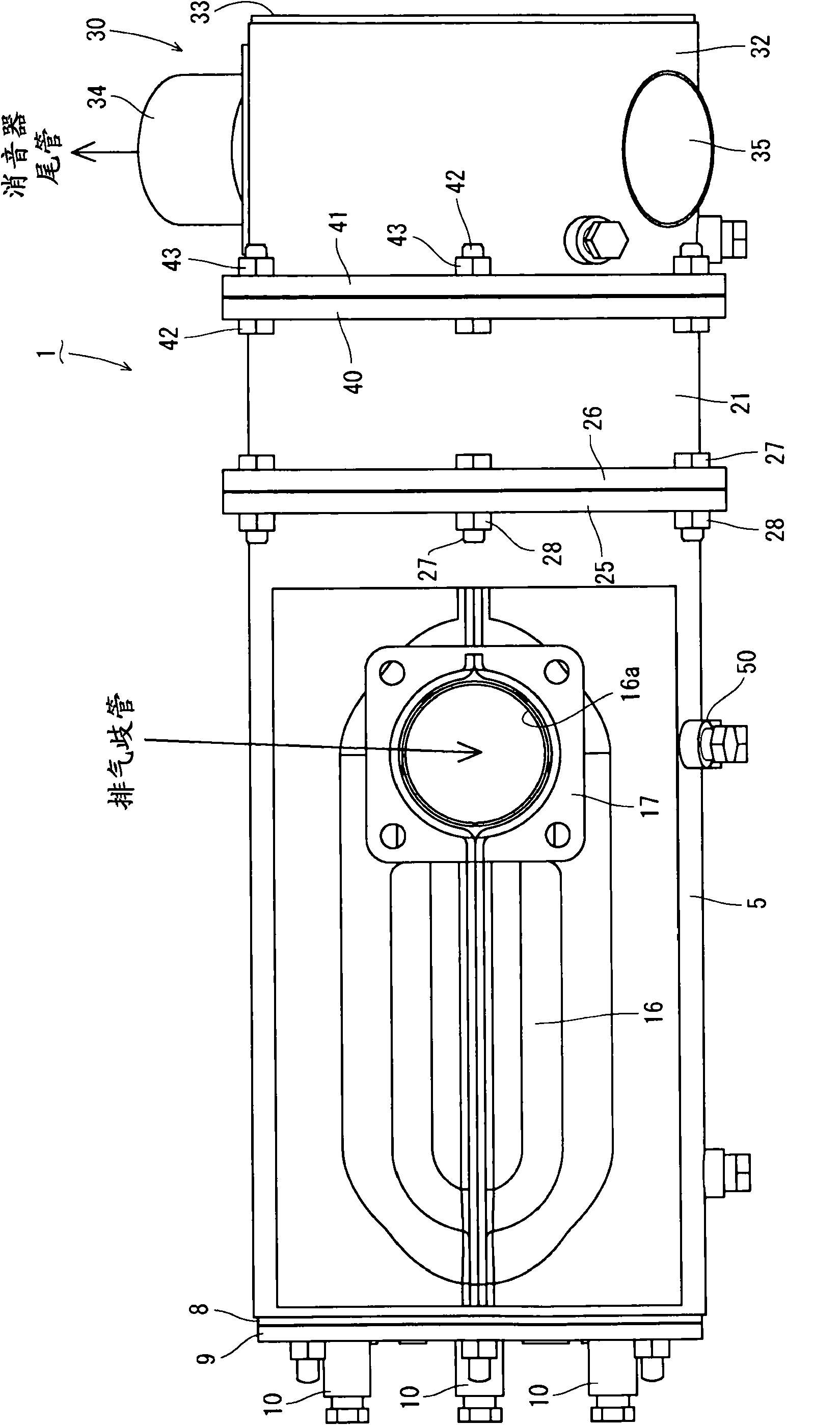

[0057] Hereinafter, embodiments embodying the present invention will be described based on the drawings. In addition, in the following description, the exhaust gas inlet 12 side of the diesel particulate filter 1 is referred to as the left side, and similarly, the muffler 30 side thereof is referred to as the right side.

[0058] First, refer to Figure 1 to Figure 5 The overall structure of the exhaust gas purification device of the first embodiment will be described. Such as Figure 1 to Figure 5 As shown, a continuous regeneration type diesel particulate filter 1 (hereinafter referred to as DPF) is provided as the exhaust gas purification device of the first embodiment. The DPF 1 is used to physically trap particulate matter (PM) and the like in exhaust gas. DPF1 is structured such that nitrogen dioxide (NO 2 ) platinum diesel oxidation catalyst 2, and a honeycomb structure soot filter 3 that continuously oxidizes and removes trapped particulate matter (PM) at relativel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com