Control device based on paperless printing test

A technology of a control device and a printer, which is applied in the fields of electrical recording technology using charge graphics, equipment for using electrical recording technology using charge graphics, and electrical recording technology, and can solve problems such as cumbersome operations and inconvenient operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

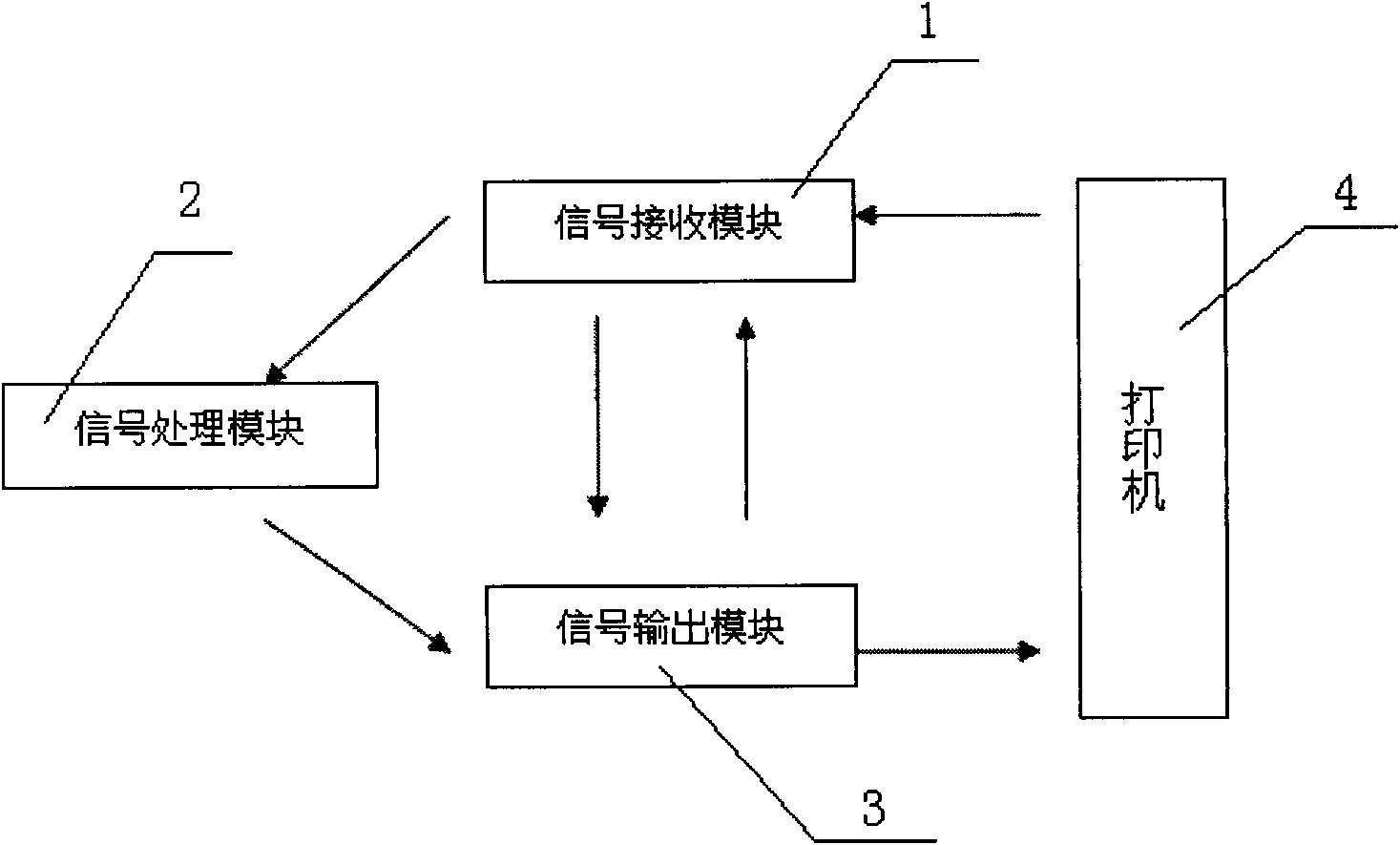

[0027] The signal receiving module (1) is used to connect the paper feeding signal control module of the printer (4), collects the paper feeding signal of the printer and the printer model information, and stores the received printer paper feeding signal and the printer model information in the storage medium, and at the same time Output printer paper feed signal, printer model information.

[0028] The signal processing module (2) can perform analog processing on the paper feed signal of the printer input by the signal receiving module (1), convert the paper feed signal of the printer from a signal mode that the printer cannot receive to a signal mode that the printer can receive, and convert the converted paper feed signal The signal is sent to the signal output module (3).

[0029] The signal output module (3) is used to receive the paper feeding signal of the printer which can be received by the printer sent by the signal processing module (2), and can also receive the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com