Method for testing response time constant of main servomotor of hydraulic turbine governor

A main relay and reaction time technology, applied in the testing of machine/structural components, engine testing, instruments, etc., can solve problems such as incompatibility, achieve the effect of simple testing process and improve simulation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

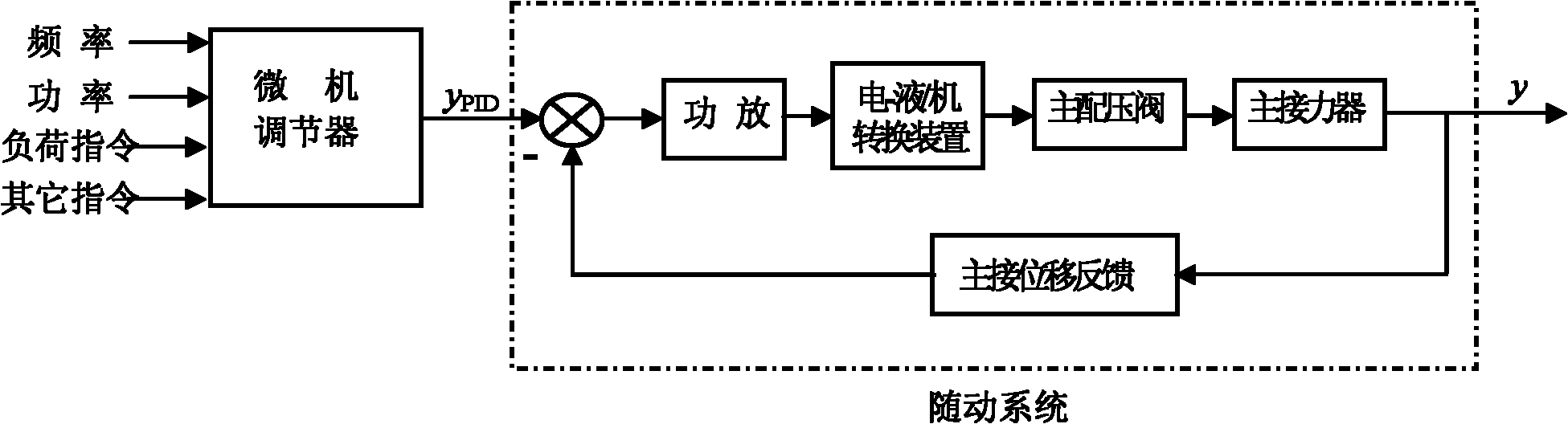

[0022] figure 1 It is a schematic diagram of the structure of the turbine governor. The modern turbine governor is mainly composed of two parts: the microcomputer governor and the servo system. The microcomputer governor is the control part of the turbine governor, and it receives instructions to adjust the governor output. The follow-up system is the actuator of the turbine governor, which generally includes power amplifier, electric / hydraulic conversion, main pressure distribution valve, and main servomotor. It accepts the output from the regulator and controls the action of the main servomotor.

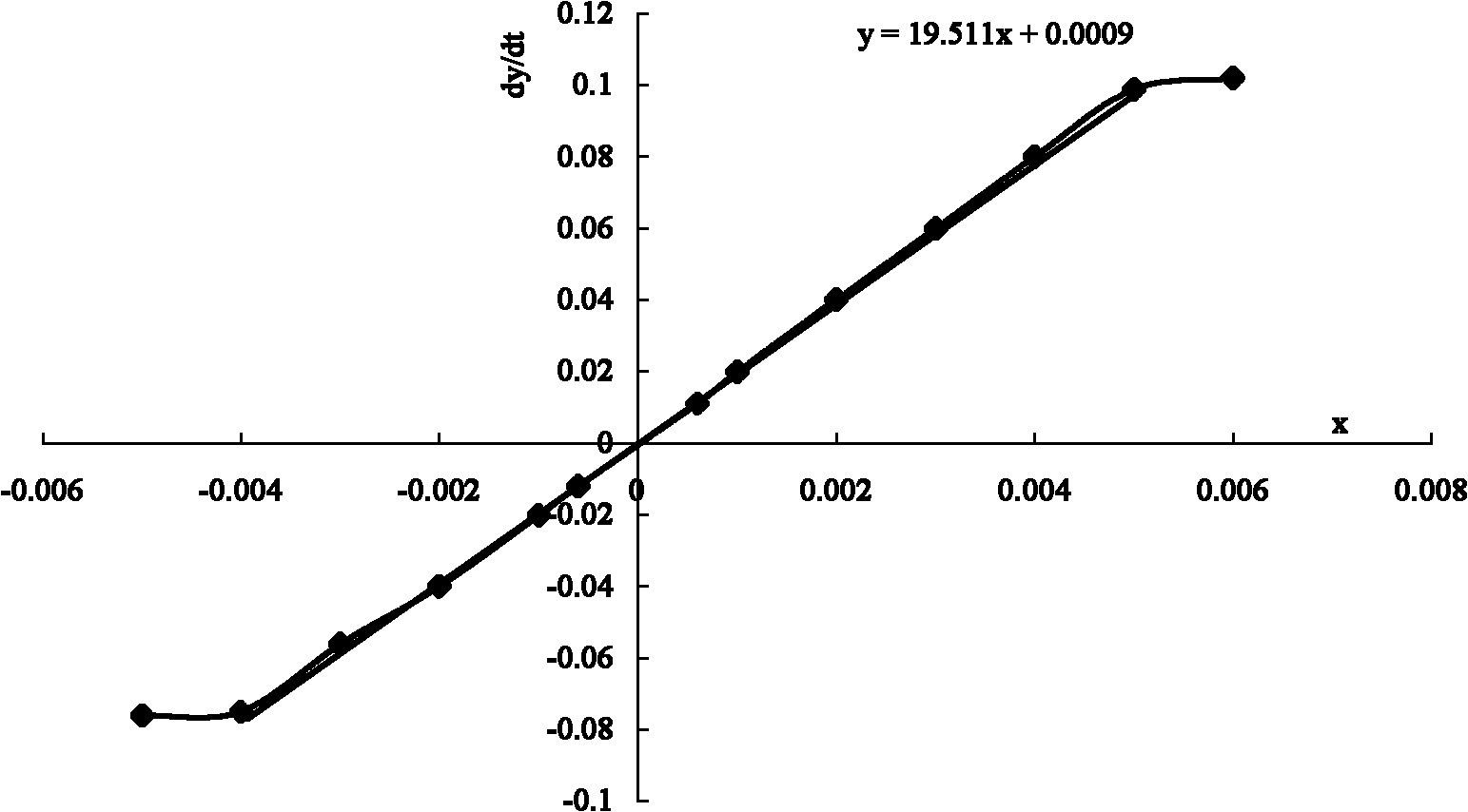

[0023] figure 2 The relationship curve between the relative speed dy / dt of the main servomotor of the water turbine governor and the frequency disturbance, the abscissa is the relative value of the frequency deviation input to the governor, the frequency reference value is 50Hz, and the ordinate is the water turbine under the corresponding input frequency deviation The relative s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com