Permanent magnet braking and frictional braking combined brake and braking method

A technology of friction braking and braking, which is applied in the direction of braking actuators, gear transmission mechanisms, mechanical equipment, etc. It can solve the problems of affecting the performance of the brakes, threatening the safety of pedestrians and themselves, and rising to a high level, so as to increase the service life and heat resistance. Good fading and small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

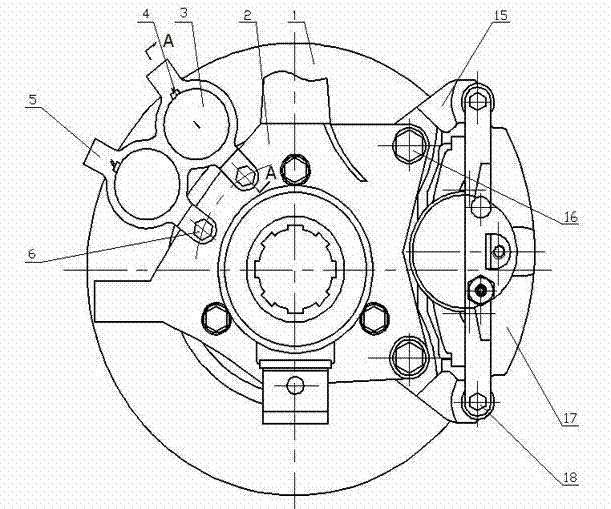

[0012] see figure 1 , the brake of the present invention is composed of a permanent magnet brake device and a friction brake device, the permanent magnet brake device is fixedly mounted on a fixed frame 5, the fixed frame 5 is connected to the steering knuckle 2 through bolts 6, and the steering knuckle 2 is connected to the brake disc 1 on. The friction braking device is composed of a brake caliper bracket 15, a brake caliper guide pin 18 and a brake caliper body 17. The brake caliper bracket 15 is connected with the steering knuckle 2 through a bolt 16, and the brake caliper body 17 is connected with a brake caliper guide pin. 18 is connected with brake caliper support 15.

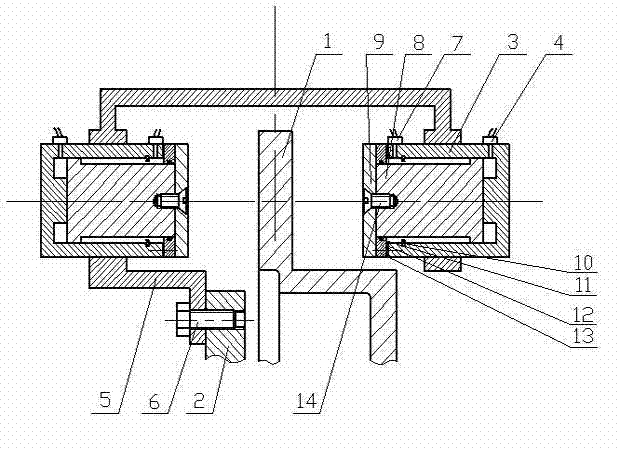

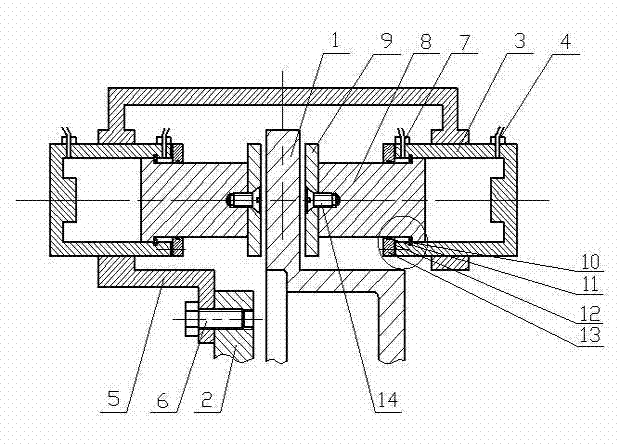

[0013] see Figure 2-4 , the permanent magnet braking device is symmetrically distributed on both sides of the brake disc 1, similarly, the fixed frame 5 connected with the permanent magnetic braking device is also symmetrically distributed on both sides of the brake disc 1, and the permanent magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com