Bovine base solution packaging raw paper

A liquid bag, cow bottom technology, applied in special paper, paper, papermaking and other directions, can solve the problems of high chemical consumption, large base paper basis, high product basis weight, less consumption, improved physical properties, and good printing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

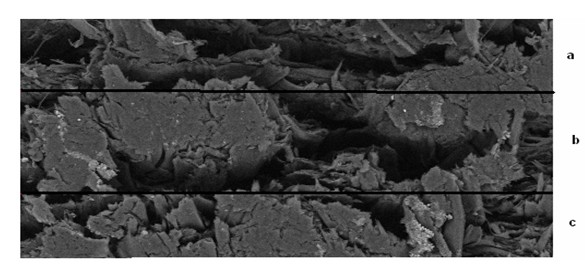

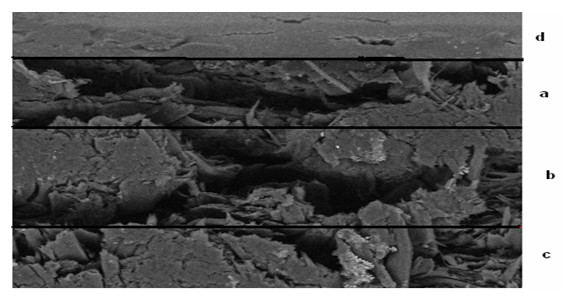

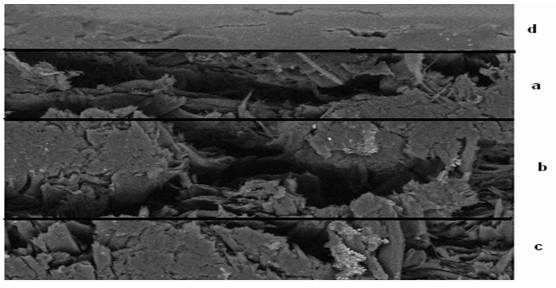

Image

Examples

Embodiment 1

[0023] The liquid-coated base paper for bovine bottom of the present invention comprises a surface layer, a core layer, a bottom layer and a coating layer.

[0024] The surface layer includes chemical broadleaf pulp and chemical softwood pulp. The weight percent of chemical broadleaf pulp is 50%, and the freeness is 350csf; the weight percent of chemical softleaf pulp is 50%, and the freeness of chemical softleaf pulp is 300csf.

[0025] The core layer includes mechanical pulp, chemical broadleaf pulp and natural color pulp. The weight percentage of mechanical pulp is 20%, and the freeness is 320 csf; the weight percentage of chemical broadleaf pulp is 10%, and the freeness is 350csf; the weight percentage of natural color pulp is 70%, and the freeness is 320csf.

[0026] The bottom layer includes natural color paste, the weight percentage of natural color paste is 100%, and the freeness is 300csf.

[0027] The coating layer includes calcium carbonate, china clay, adhesive, ...

Embodiment 3

[0039] The liquid-coated base paper for bovine bottom of the present invention comprises a surface layer, a core layer, a bottom layer and a coating layer.

[0040] The surface layer includes chemical broadleaf pulp and chemical softwood pulp. The weight percentage of chemical broadleaf pulp is 70%, and the freeness is 380csf; the weight percentage of chemical softleaf pulp is 30%, and the freeness of chemical softleaf pulp is 340csf.

[0041] The core layer includes mechanical pulp, chemical broadleaf pulp and natural color pulp. The weight percentage of mechanical pulp is 20%, and the freeness is 340csf; the weight percentage of chemical broadleaf pulp is 20%, and the freeness is 390csf; the weight percentage of natural color paste is 60%, and the freeness is 340csf.

[0042] The bottom layer includes natural color paste, the weight percentage of natural color paste is 100%, and the freeness is 340csf.

[0043] The coating layer includes calcium carbonate, china clay, adhe...

Embodiment 4

[0046] The liquid-coated base paper for bovine bottom of the present invention comprises a surface layer, a core layer, a bottom layer and a coating layer.

[0047] The surface layer includes chemical broadleaf pulp and chemical softwood pulp. The weight percent of chemical broadleaf pulp is 55%, and the freeness is 320csf; the weight percent of chemical softleaf pulp is 45%, and the freeness of chemical softleaf pulp is 300±40csf.

[0048] The core layer includes mechanical pulp, chemical broadleaf pulp and natural color pulp. The weight percentage of mechanical pulp is 25%, and the freeness is 320csf; the weight percentage of chemical broadleaf pulp is 10%, and the freeness is 360csf; the weight percentage of natural color paste is 65%, and the freeness is 320csf.

[0049] The bottom layer includes natural color paste, the weight percentage of natural color paste is 100%, and the freeness is 340csf.

[0050] The coating layer includes calcium carbonate, china clay, adhesiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com