Low-density high-strength conductive rubber and preparation method thereof

A conductive rubber, low-density technology, applied in the field of low-density and high-strength conductive rubber and its preparation, can solve the problem that conductive silicone rubber cannot have high strength and high conductivity at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

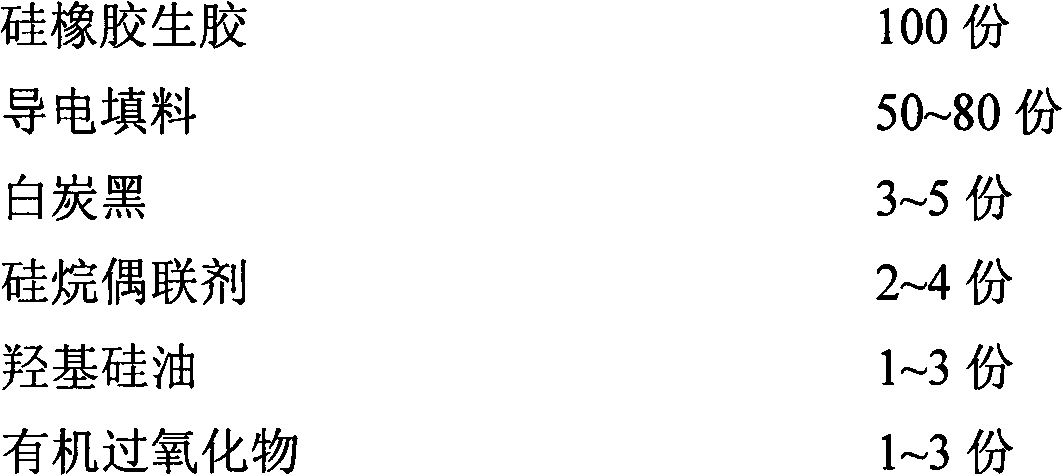

[0014] Embodiment 1: The raw material components of low-density high-conductivity rubber are as follows: (both are parts by mass)

[0015]

[0016] The preparation method is as follows:

[0017] Methyl vinyl silicone rubber raw rubber (110-2, Laizhou Jintai Silicon Industry Co., Ltd.) was mixed on a double-roll mill to the front roll of the tight package, and precipitated silica (JB-180, Zhejiang Yingluohua Chemical Co., Ltd.), after mixing evenly, add nickel-plated carbon fiber with a length of 2-3cm (Ni-CF, carbon fiber continuous nickel-plating production process and its shielding composite material, Journal of Composite Materials, 2010 05 issue), mix evenly, and then Add vinyltriethoxysilane, hydroxy silicone oil and 2,5-dimethyl-2,5-di-tert-butyl peroxyhexane, thin pass 8 times, one-stage vulcanization and two-stage vulcanization to obtain conductive rubber. (First-stage vulcanization conditions: flat machine, 10MPa, 160±5°C, 10min, second-stage vulcanization conditio...

Embodiment 2

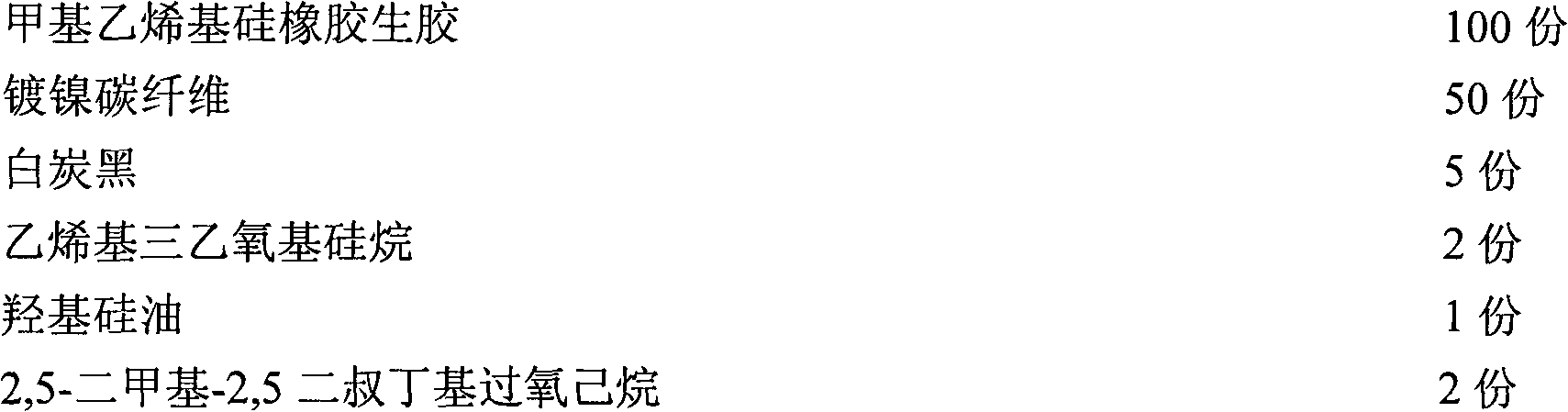

[0018] Embodiment 2: The raw material components of low-density high-conductivity rubber are as follows: (both are parts by mass)

[0019]

[0020]

[0021] The preparation method is as follows:

[0022] Mix the methyl vinyl silicone rubber raw rubber on the double-roll mill to the front roll of the tight package, add white carbon black, mix evenly, add nickel-plated carbon fiber, mix evenly, and then add vinyl triethoxysilane , hydroxy silicone oil and 2,5-dimethyl-2,5-di-tert-butylperoxyhexane, thin pass 8 times, one-stage vulcanization, and two-stage vulcanization to obtain conductive rubber. Its density is 1.26g / cm 3 ; The volume resistivity is 0.26Ω·cm; the tensile strength is 2.97MPa; the elongation at break is 197%.

Embodiment 3

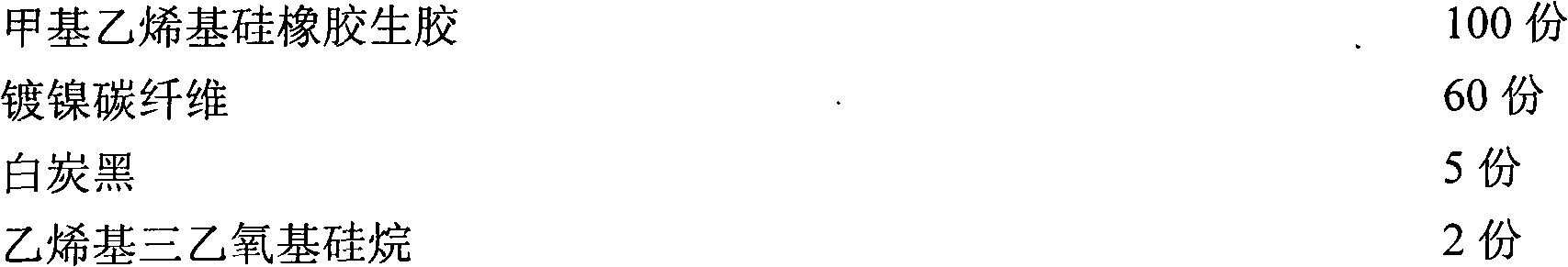

[0023] Embodiment 3: The raw material components of low-density high-conductivity rubber are as follows: (both are parts by mass)

[0024]

[0025] The preparation method is as follows:

[0026] Mix the methyl vinyl silicone rubber raw rubber on the double-roll mill to the front roll of the tight package, add white carbon black, mix evenly, add nickel-plated carbon fiber, mix evenly, and then add vinyl triethoxysilane , Hydroxy silicone oil, 2,5-dimethyl-2,5-di-tert-butylperoxyhexane, thin pass 8 times, one-stage vulcanization, and two-stage vulcanization to obtain conductive rubber. Its density is 1.31g / cm 3 ; The volume resistivity is 0.09Ω·cm; the tensile strength is 3.2MPa; the elongation at break is 180%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com