Yarn tensioner

A technology of tensioner and yarn, applied in the direction of thin material processing, textile and paper making, loom, etc., can solve problems such as difficulties, and achieve the effect of less risk of yarn breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

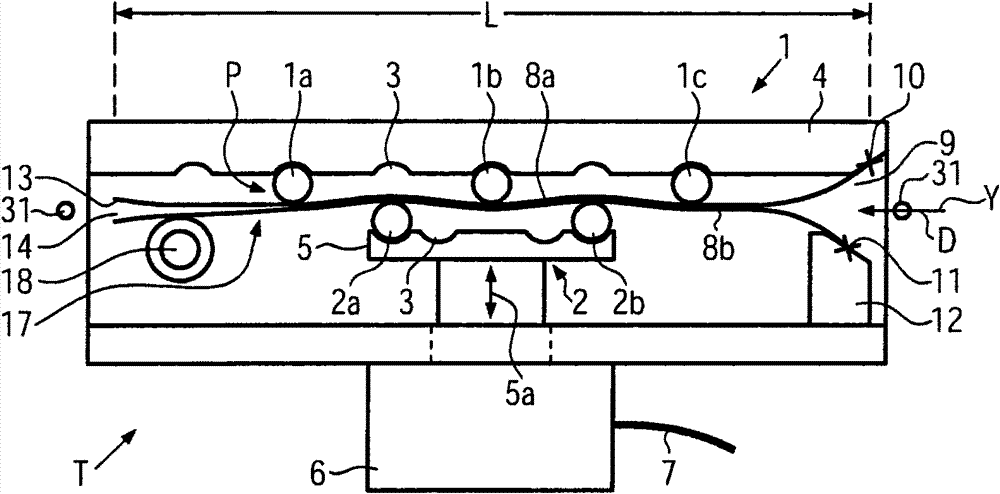

[0035] figure 1 An embodiment of a yarn tensioner T is schematically shown, especially designed to handle heavy yarn qualities. The yarn tensioner T is a so-called heavy-duty yarn tensioner, used e.g. Speed operation, i.e. yarn tensioners for applications where the advancing yarn requires a relatively high yarn tension even in the event of unavoidable knots, tangles or irregular passages of the yarn The situation with the yarn tensioner T remains relatively constant as set and allows for example knots to pass smoothly without severe tension peaks without the risk of yarn breakage and the set yarn The thread tension does not change much through the passage of the knot and is quickly regained after the passage of the knot.

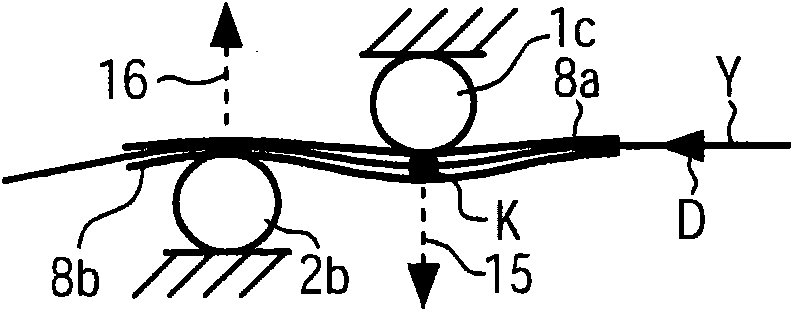

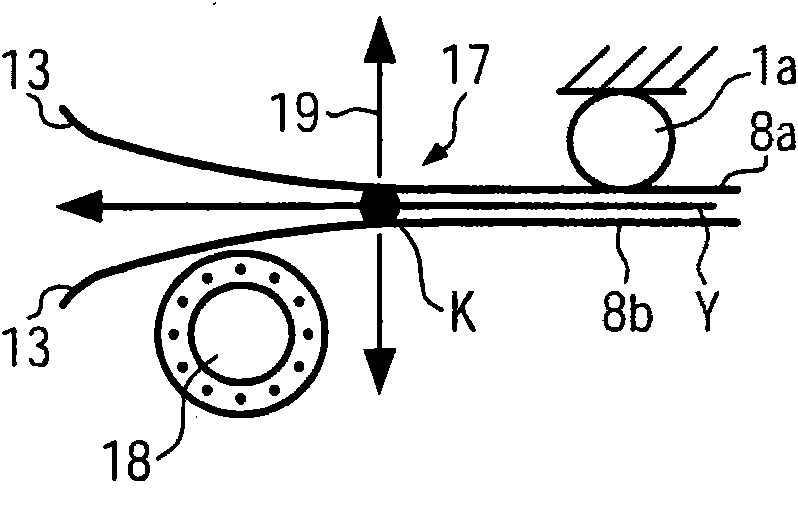

[0036] exist figure 1 The yarn tensioner T in is a combination of a deflection tensioner and a clamping or blade tensioner and comprises a series of deflection elements on both sides of the yarn path P of the yarn traveling in the yarn travel direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com