Manipulator of high-altitude live working vehicle

A technology of live work and manipulators, which is applied in the field of special vehicles, can solve the problems of safety difficulties in manual live work, limit the development of manual live work, and high cost, and achieve the effects of reducing design costs, system weight reduction, and design weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is described in detail as follows in conjunction with accompanying drawing and embodiment:

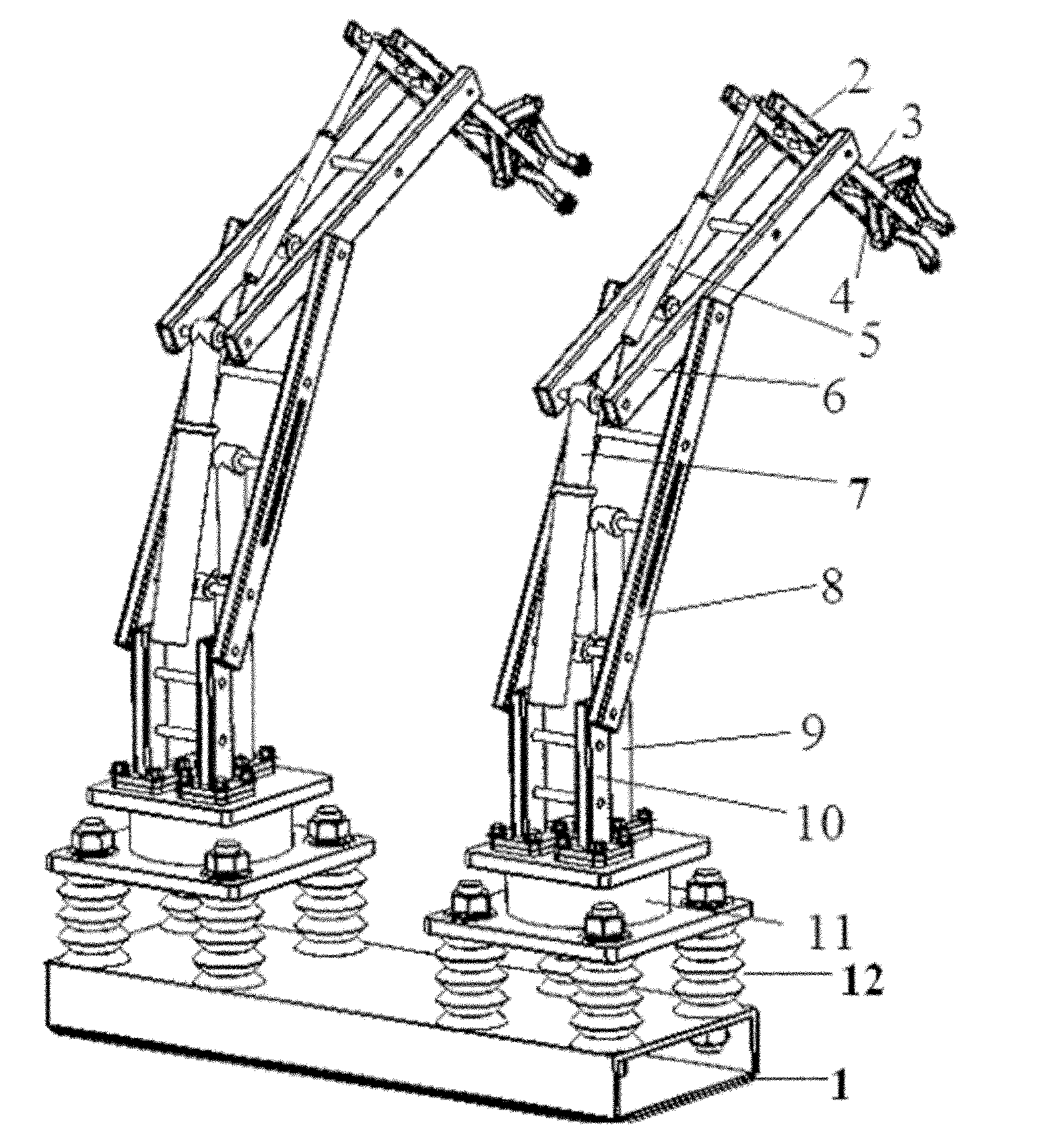

[0020] The structure of the high-altitude live working vehicle manipulator described in the present invention, as figure 1 As shown, it includes a base 1 and first and second manipulators, the base 1 is installed on the chassis of the car, and the first and second manipulators are installed on the base 1 side by side.

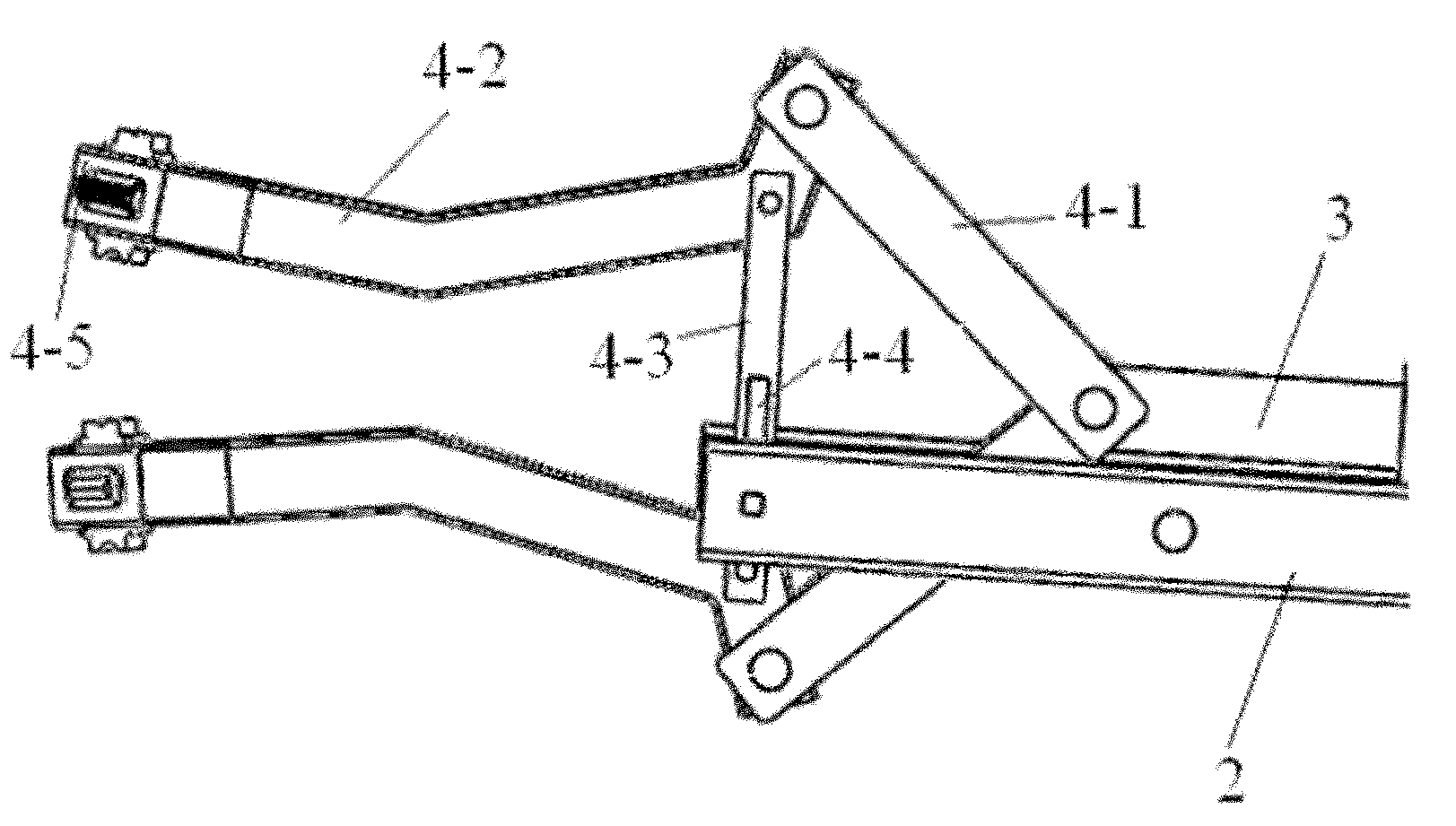

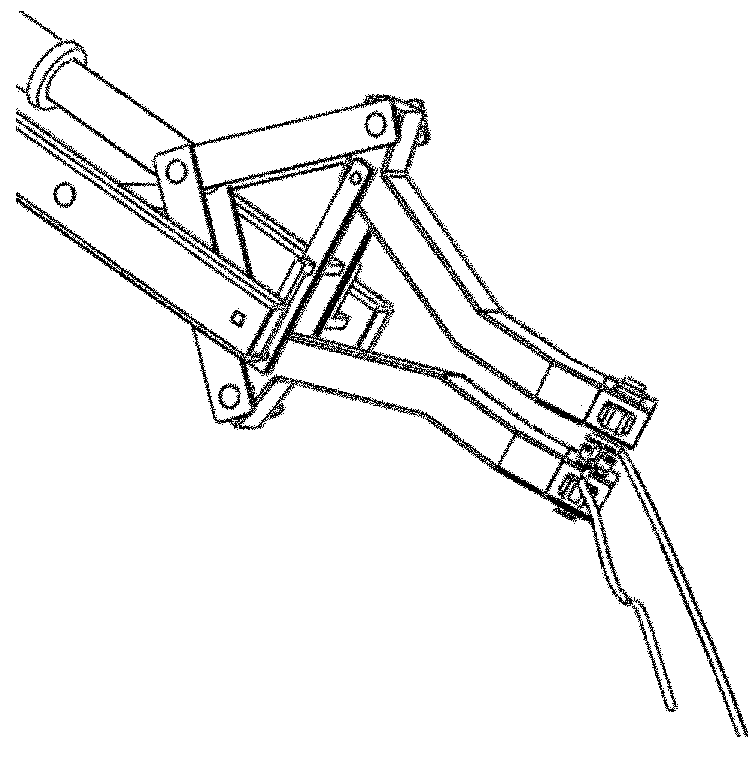

[0021] The first manipulator includes a first rotary table 11 driven by a hydraulic motor, a first set of four insulating parts 12, a first lower arm 10 and a first middle arm 8 of a rectangular frame structure composed of rods and slats , the first upper arm 6, the first forearm 2, the first end mechanism 4, the first middle arm hydraulic cylinder 9, the first upper arm hydraulic cylinder 7, the first forearm hydraulic cylinder 5, and the first end mechanism hydraulic cylinder 3; The first turntable 11 is fixed on the base 1 through the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com