High rigidity and flexibility locating clamp and locating method of locating clamp

A flexible positioning and high-rigidity technology, used in positioning devices, clamping, manufacturing tools, etc., can solve the problems of uneven wear of the center pin and the side of the groove, high installation requirements of the combined device, affecting the positioning accuracy, etc., to achieve a simple structure. , The effect of realizing flexible automated production process, improving precision and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

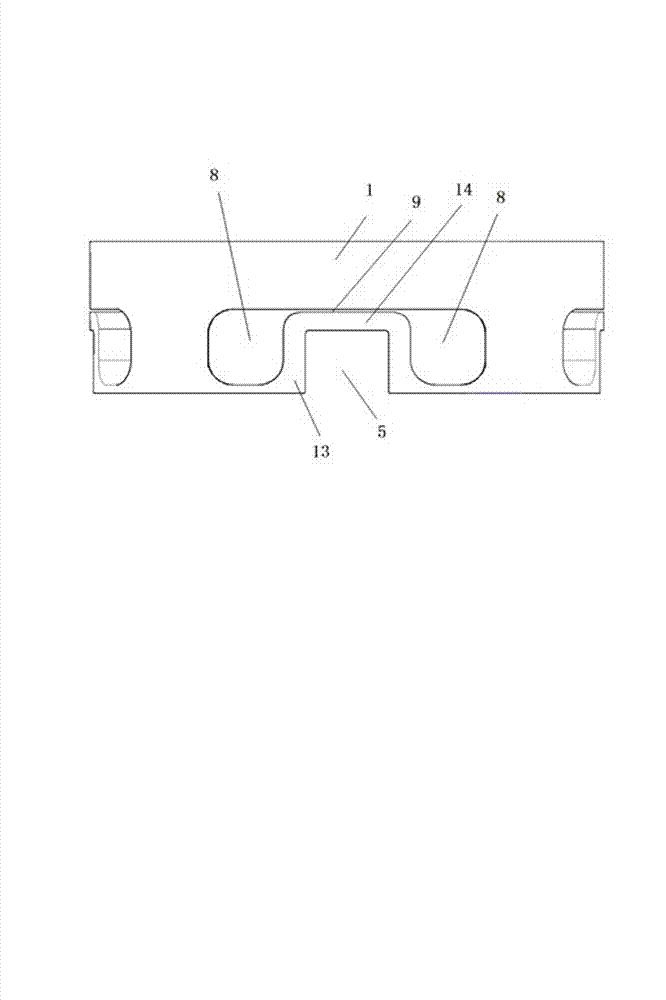

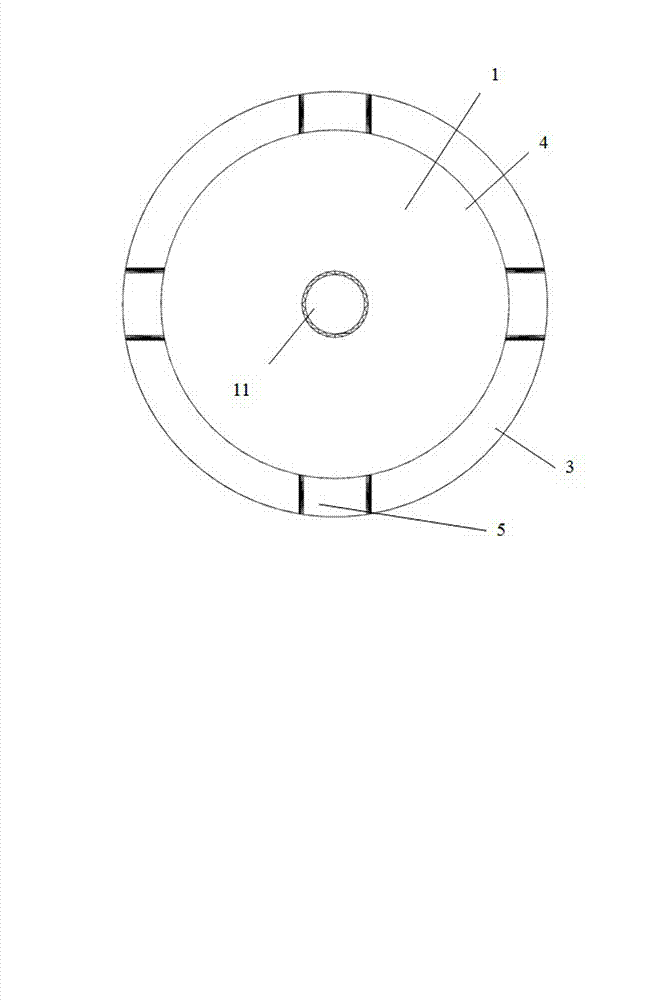

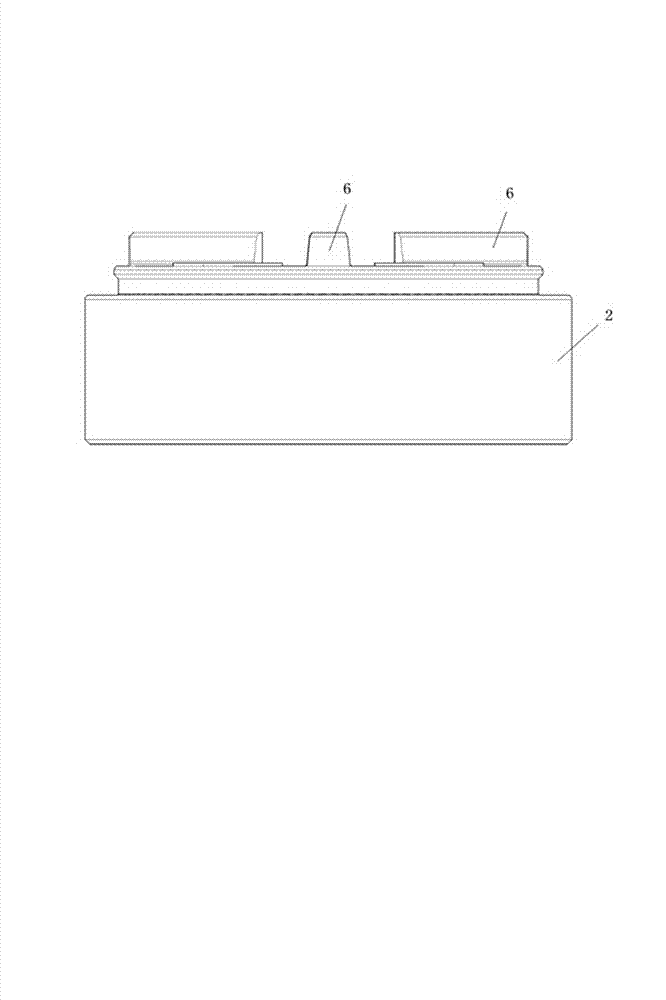

[0020] A high-rigidity flexible positioning fixture, including a workpiece supporting plate 1 and a chuck base body 2, the workpiece supporting plate 1 and the chuck base body 2 are connected by a connecting device, and it is characterized in that the lower end of the workpiece supporting plate 1 is provided with a boss 3, and the convex A Z-axis positioning surface 4 is provided on the end surface of the table 3, and a plurality of positioning grooves 5 are provided on the boss 3. A plurality of positioning teeth 6 matching with the positioning grooves 5 are provided on the upper end of the chuck base body 2, and a plurality of positioning teeth 6 are arranged on the upper end of the chuck base body 2. The Z-axis reference plane 7 matched with the Z-axis positioning plane 4 is provided with avoidance holes 8 on both sides of each positioning groove 5, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com