Bolster and buffer welding tool

A technology of welding tooling and bolsters, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as incompatibility of size bolsters, improve the quality of welding seams, and reduce welding difficulty , the effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

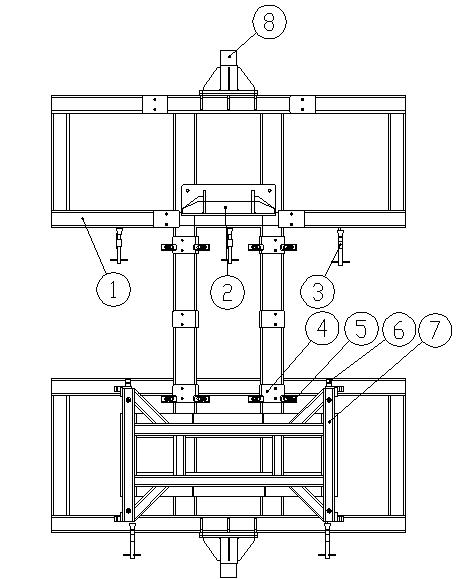

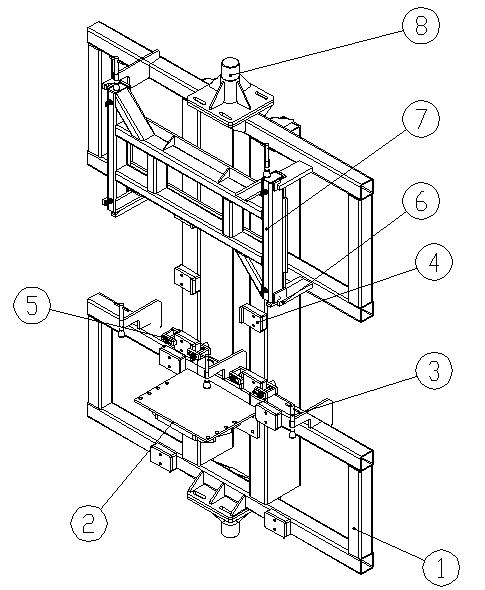

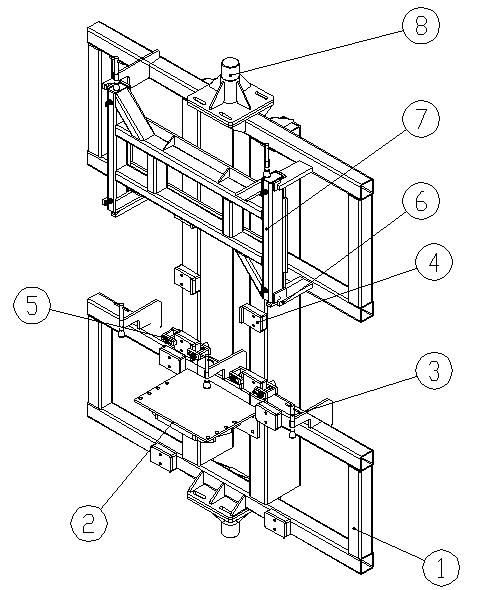

[0017] see figure 1 , the present invention is a kind of pull pillow slow welding tool, including tool steel structure 1, bolster clamping tool 7, bolster positioning block 6, platen device 5, positioner, coupler plate mounting seat 2, steel and aluminum pad 4, Compression device 3. The overall structure of the tooling is quenched and tempered and flattened after welding, and has sufficient strength to ensure the normal use of the welded tire.

[0018] The coupler plate mounting seat 2 installed at one end of the tooling steel structure surface is connected to the tooling steel structure 1 with bolts. The centerline of the coupler plate mounting seat coincides with the centerline of the tooling steel structure to prevent the welded parts from mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com