Method for leveling side-wall welding deformation of urban rail vehicle

A technology for welding deformation and urban rail vehicles, which is applied in the field of leveling, can solve the problems that aluminum alloy hollow extruded profiles cannot be leveled, and the leveler cannot be used, so as to avoid flammable and explosive equipment, and achieve remarkable leveling effects. Simple effects using the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A method for welding deformation and leveling of side walls of urban rail vehicles, the steps of the method are as follows:

[0030] 1. Optional equipment: the welding machine is a MIG welding machine;

[0031] 2. Determine the position of the weld:

[0032] First use a flat ruler to measure the side wall panels, determine the deformation area, and clean and polish the area to be welded;

[0033] Mark the slotting line with tape measure, flat ruler and marker in the deformation area 50~100mm;

[0034] 3. Slotting

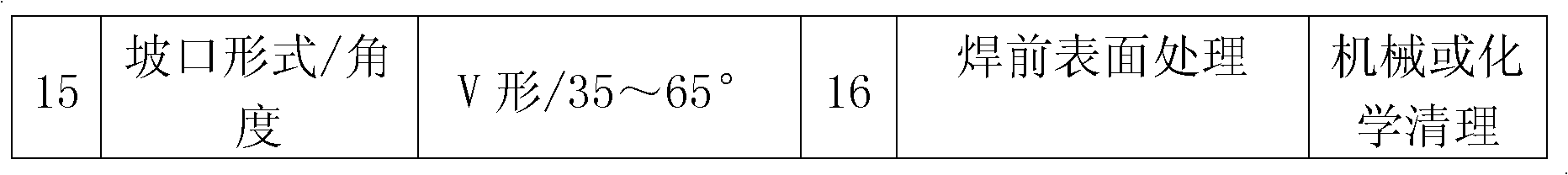

[0035] Use a straight grinder or a circular saw to groove the original weld. The groove shape is V-shaped, the groove depth is 2 / 3 of the original solution depth, and the V-shaped groove angle is 35-65°;

[0036] 4. Welding

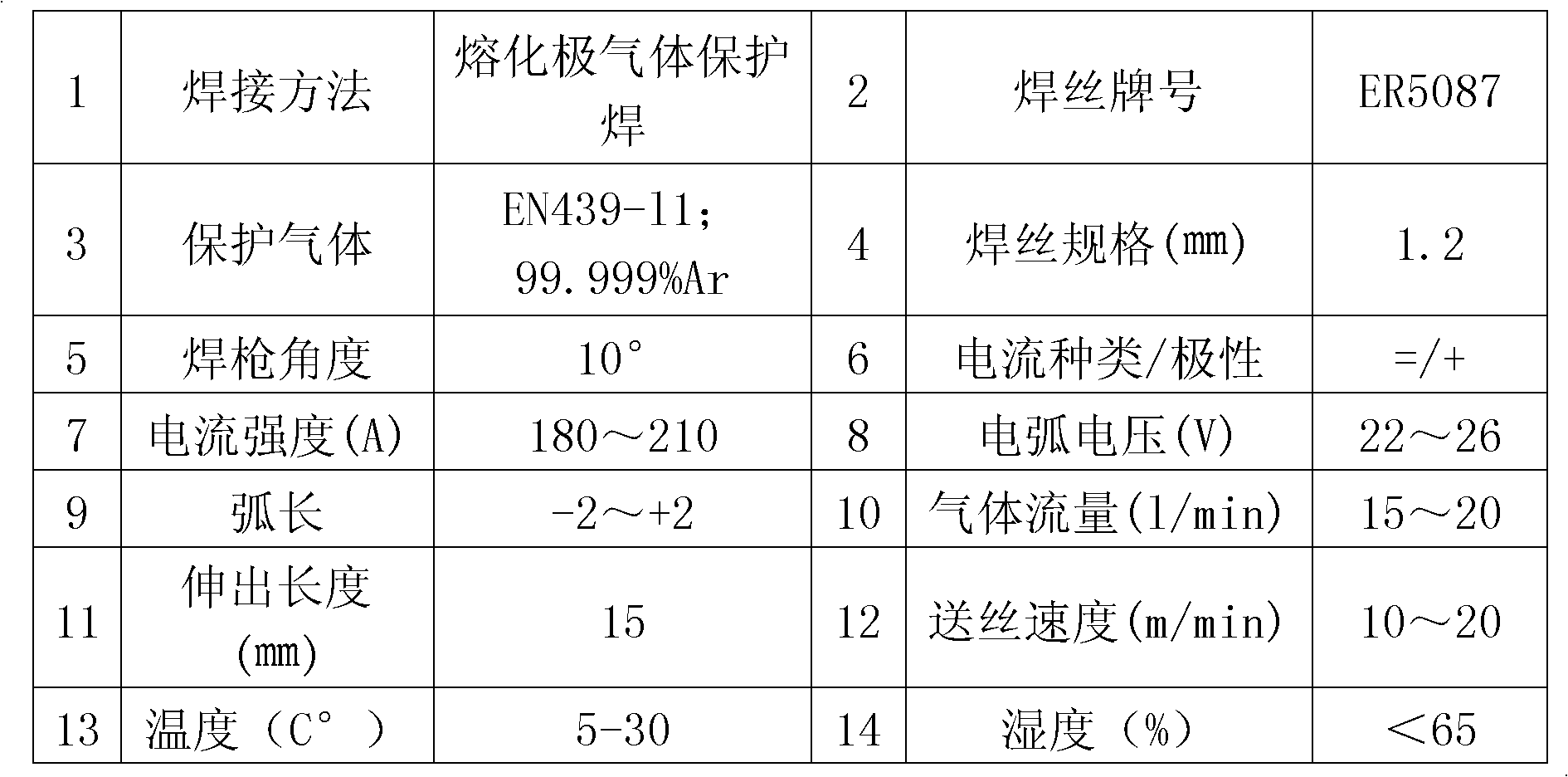

[0037] The welding technical parameters are as follows:

[0038]

[0039]

[0040] 5. The welding operation and cold work are carried out at the same time. During the welding operation, two people work together. While the welder is performing the weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com