Device for pretreating waste incineration smoke

A waste incineration and flue gas technology, which is applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high operating costs, high pressure of bag dust removal, etc., and achieve the effects of load reduction, good purification and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

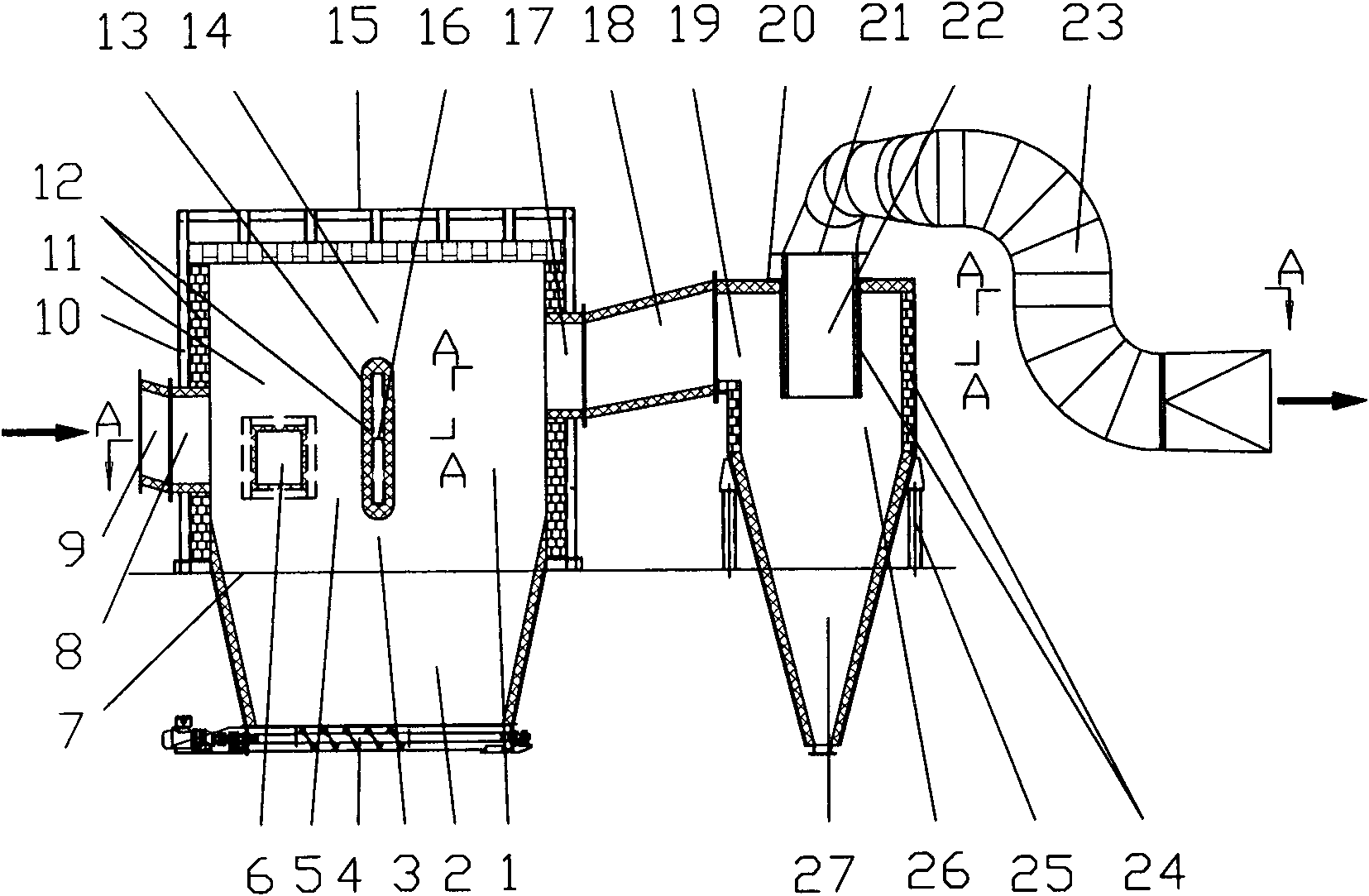

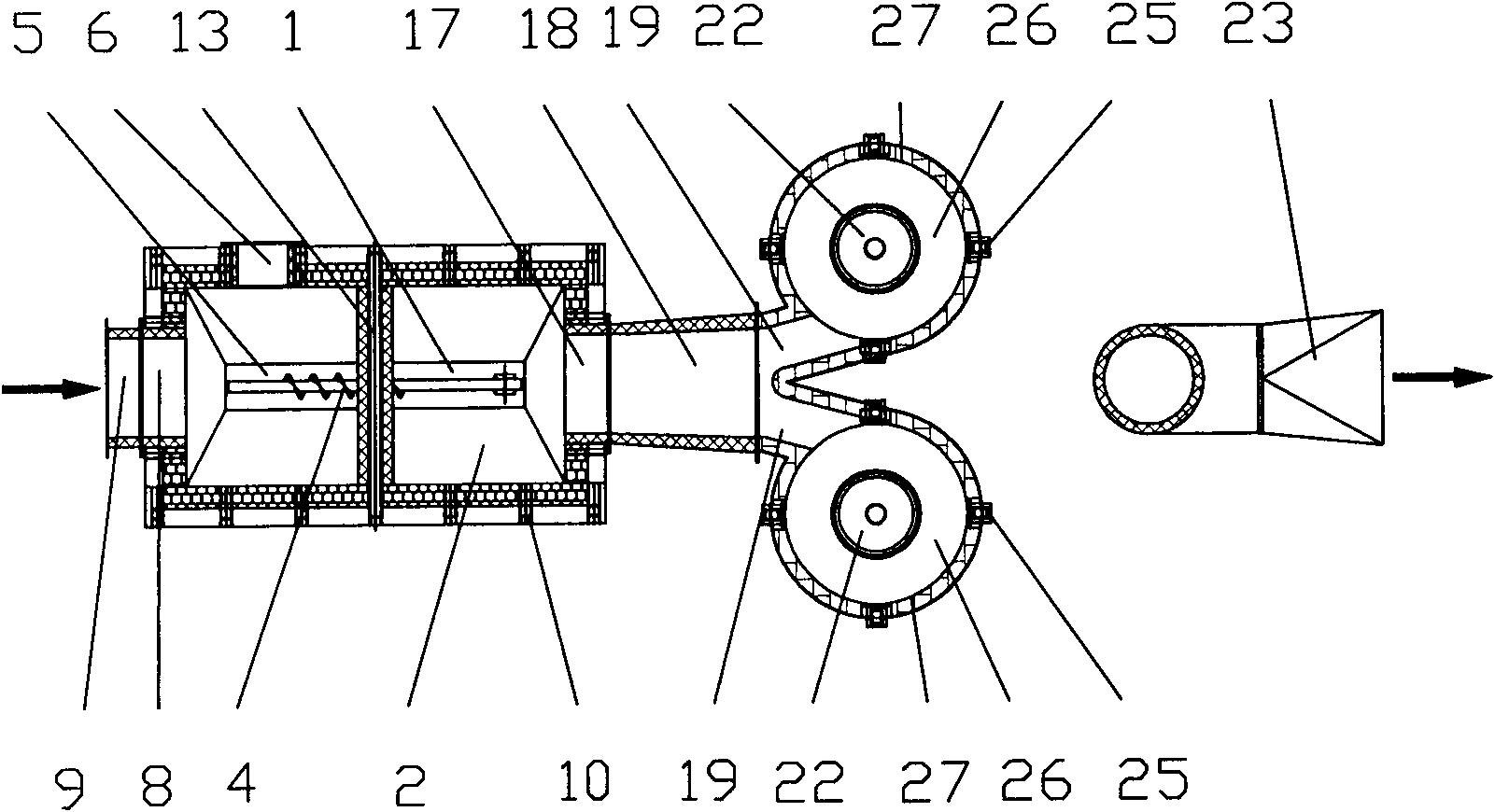

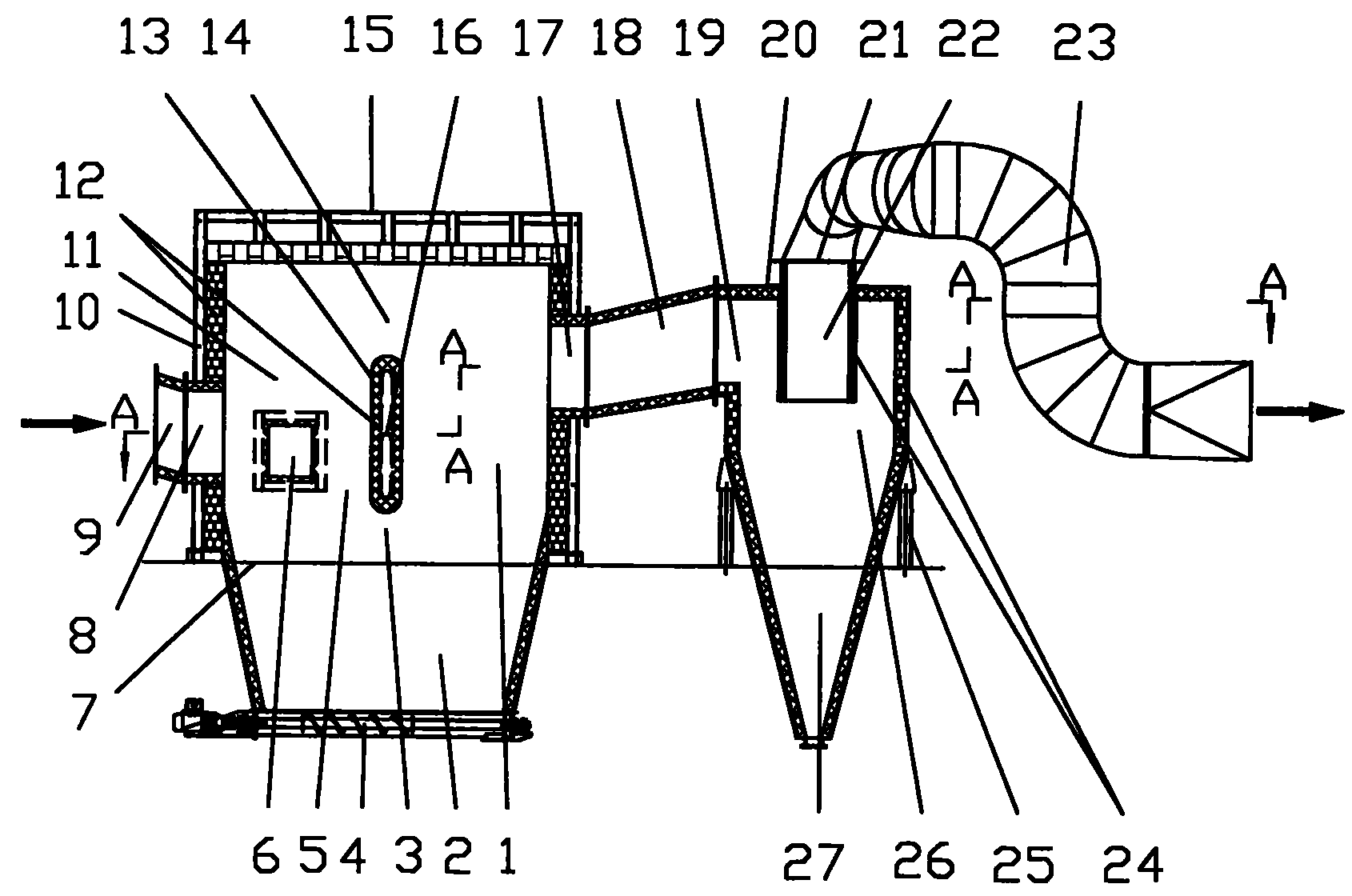

[0013] Such as figure 1 with figure 2 Shown: a pretreatment device for waste incineration flue gas, which includes a gravity settling chamber 15 and a cyclone dust collector 20. The gravity settling chamber 15 and the cyclone dust collector 20 are respectively installed on the fixed wall 7 through the integral frame 10 made of metal material and the bracket 25 made of metal material.

[0014] The upper part of the gravity settling chamber 15 is the gravity settling chamber furnace chamber 11, and the middle damping partition wall 13 divides the gravity settling chamber furnace chamber 11 into the smoke furnace chamber 5 and the smoke discharge furnace chamber 1 in the middle of the gravity sedimentation chamber furnace chamber 11. The middle of the middle damping partition wall 13 is the middle damping partition wall frame 16 made of metal material. Both sides of the inner wall of the gravity settling chamber furnace chamber 11 and the middle damping partition wall 13 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com