Flyback integrated magnetic converter used for multi-circuit LED (light-emitting diode) driving

A technology of LED driver and converter, applied in the direction of electric lamp circuit layout, lighting device, light source, etc., can solve the problems of large loss, influence of current sharing accuracy magnification and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

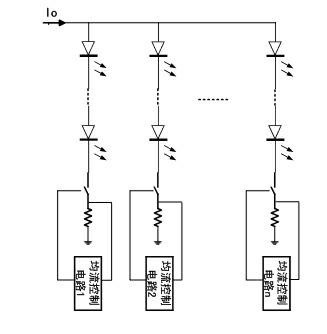

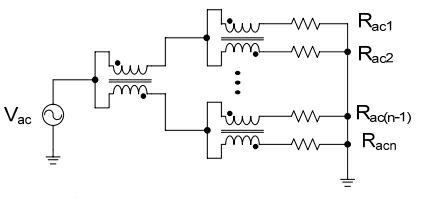

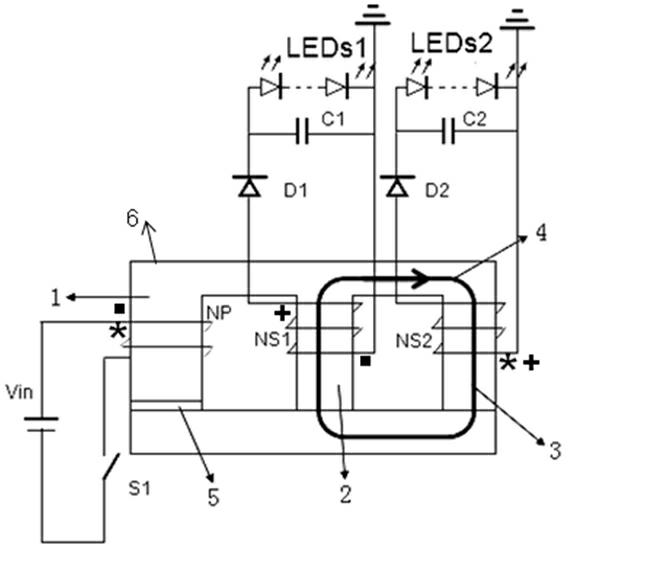

[0015] Solution 1 of the present invention is to provide a flyback magnetic integrated converter that can be used to drive multiple LEDs, including a DC power supply, a primary switch tube, a magnetic core, a primary winding, at least two secondary windings, and corresponding secondary windings. The side rectifier circuit and the LED string load are characterized in that: the magnetic core has at least three magnetic columns, one of which has an air gap to form the excitation inductance energy storage magnetic circuit of the converter, and the other magnetic columns are not provided with air gaps. gap; the primary winding is wound on the magnetic column with an air gap, and the secondary winding is wound on the magnetic column without an air gap in a one-to-one correspondence, and the primary winding passes through the primary The side switch is connected with the DC power supply; the secondary windings are respectively connected with the LED load through a rectification and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com