Integrated system and method for monitoring mix proportion

A technology of mixing ratio, monitoring and management, applied in the directions of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of waste of enterprise resources, poor roads and poor traffic conditions, and increased production costs of enterprises, and achieve systematic and integrity, improving the level of inspection management, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

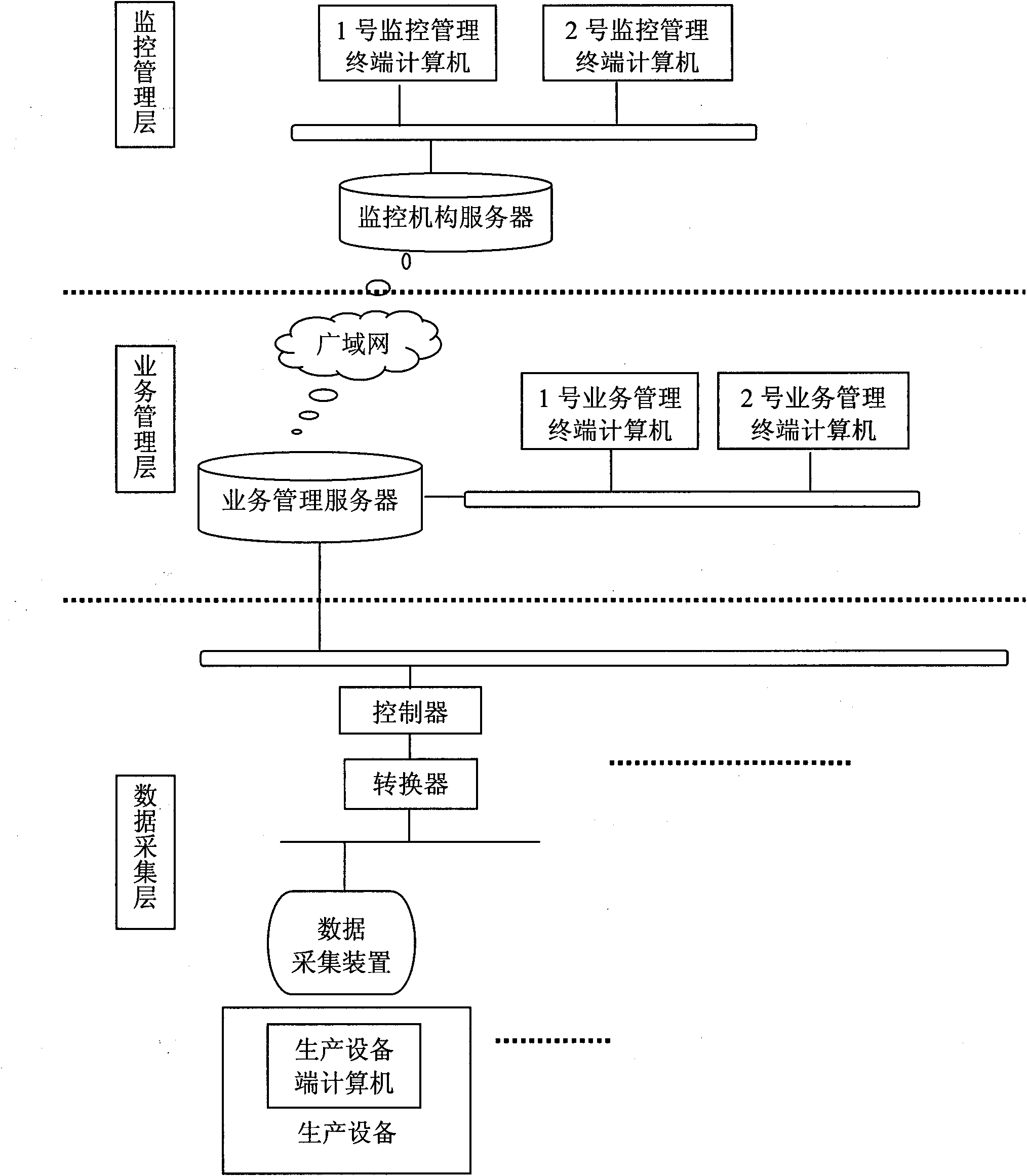

[0019] The mixing ratio monitoring integrated system and method are composed of hardware and software; the hardware part includes a plurality of production equipment, a plurality of production equipment terminal computers, a plurality of data acquisition devices, a plurality of controllers, a plurality of business management terminal computers, Multiple monitoring and management terminals, business management servers, and monitoring agency servers; the data acquisition device includes multiple load cells, multiple converters, and multiple controllers; the data acquisition device is divided into three structures: 1. The first structure , automatically obtain information from the software that comes with the mixer, and collect its working signals and operating parameters; 2. The second structure is divided into two cases: a. The first case is equipped with aggregate batching machine and mixer The load cell of the system obtains the weight signal of the aggregate, and then rectifi...

Embodiment 2

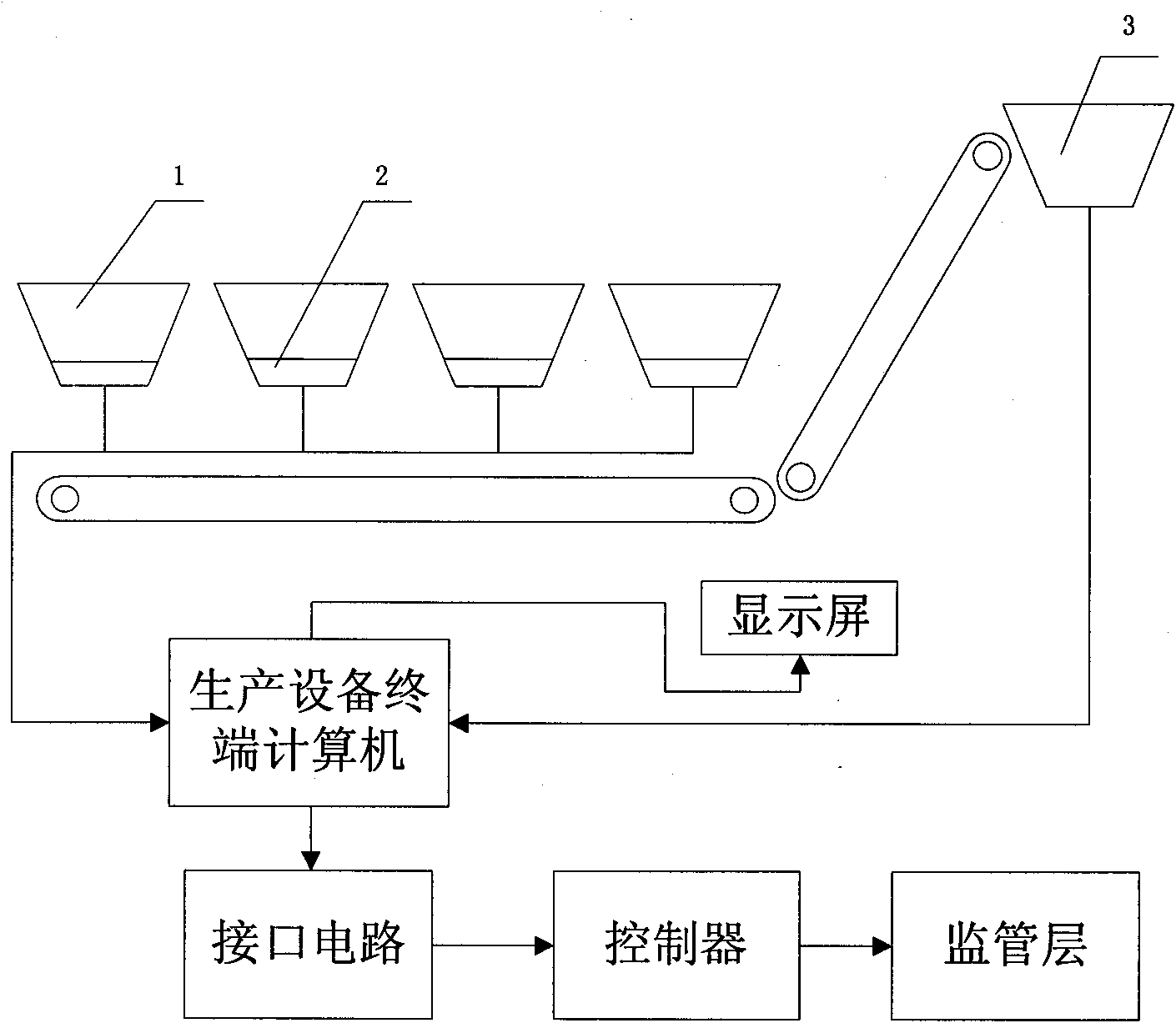

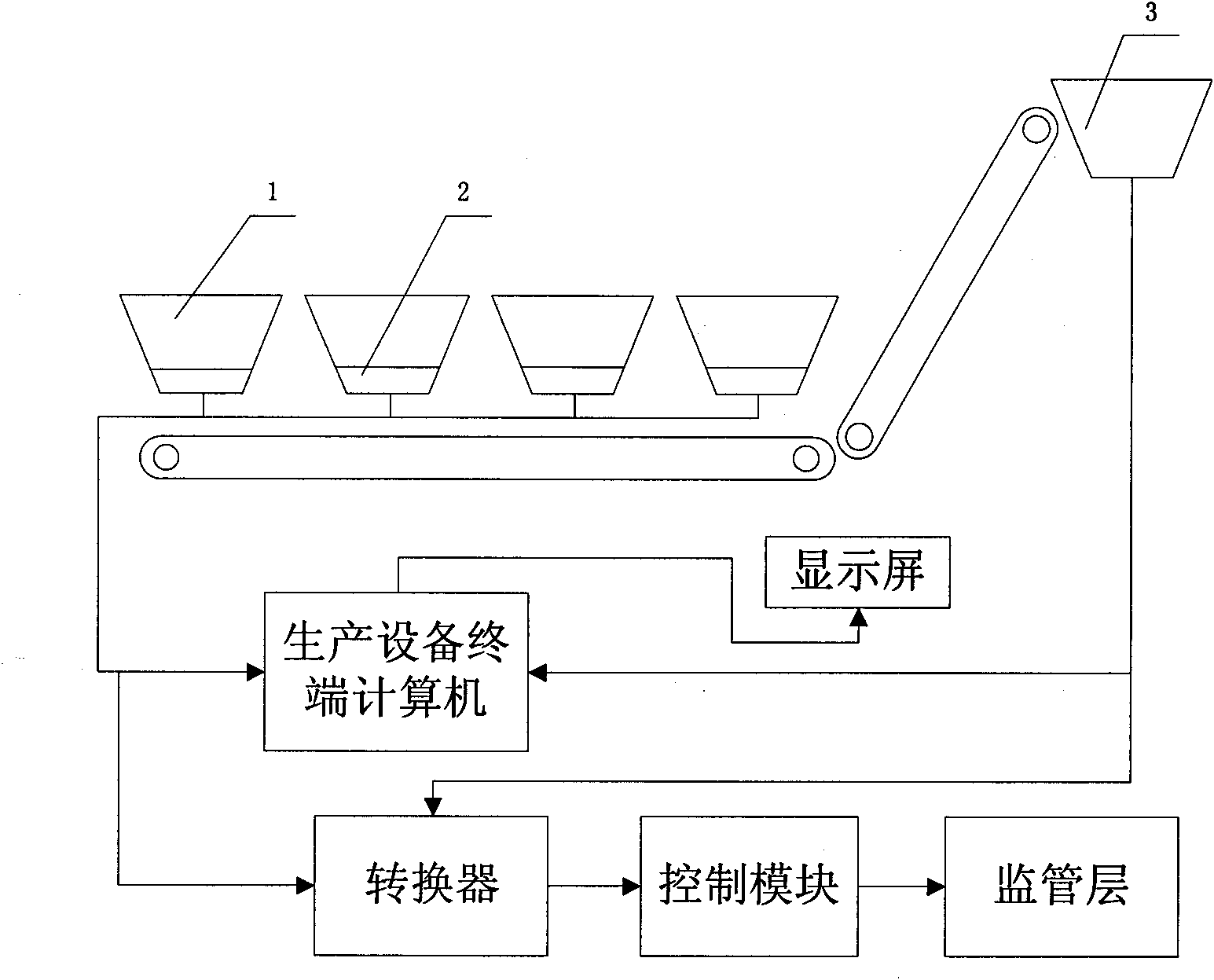

[0025] The aggregate batching machine and mixer of the mixing station can choose Shandong Yuanyou JS series, Shandong Dezhou Fangjian, Shandong Jianyou, with similar structures and functions. refer to figure 2 , taking Shandong Yuanyou JS series aggregate batching machine and mixer as an example, the four aggregate hoppers are respectively filled with sand and three different crushed stones according to the C30 mix ratio, and the sand and crushed stones are poured from the hoppers in turn On the conveyor belt, the conveyor belt has a weighing device, and the weight of each ingredient can be obtained through the difference between each weighing. After the four ingredients are poured, they are conveyed by the conveyor belt and lifted to the cement pouring place, where a load cell is also installed, and the cement is poured into the hopper according to the mixing ratio, and then stirred. The hopper is set above the transport vehicle, which can conveniently load the concrete int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com