Intelligent dynamic weightlessness scale

An intelligent dynamic and loss-in-weight scale technology, which is applied in the direction of automatic feeding/discharging weighing equipment, measuring devices, instruments, etc., can solve the problems of unsatisfactory feeding accuracy and speed, poor stability, etc., and achieve stability Guaranteed stability, smooth operation, consistency and uniformity guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the embodiments and with reference to the accompanying drawings.

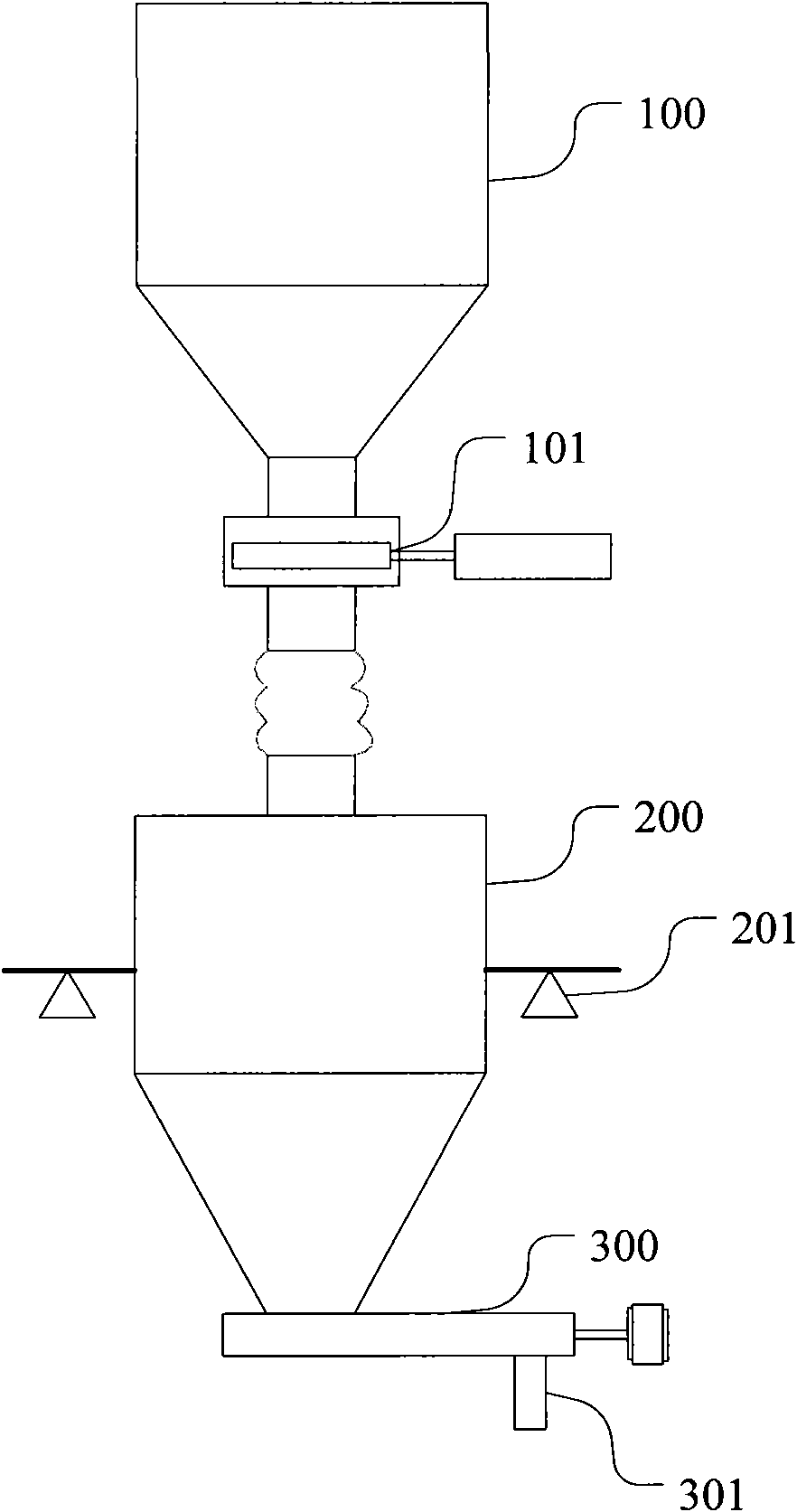

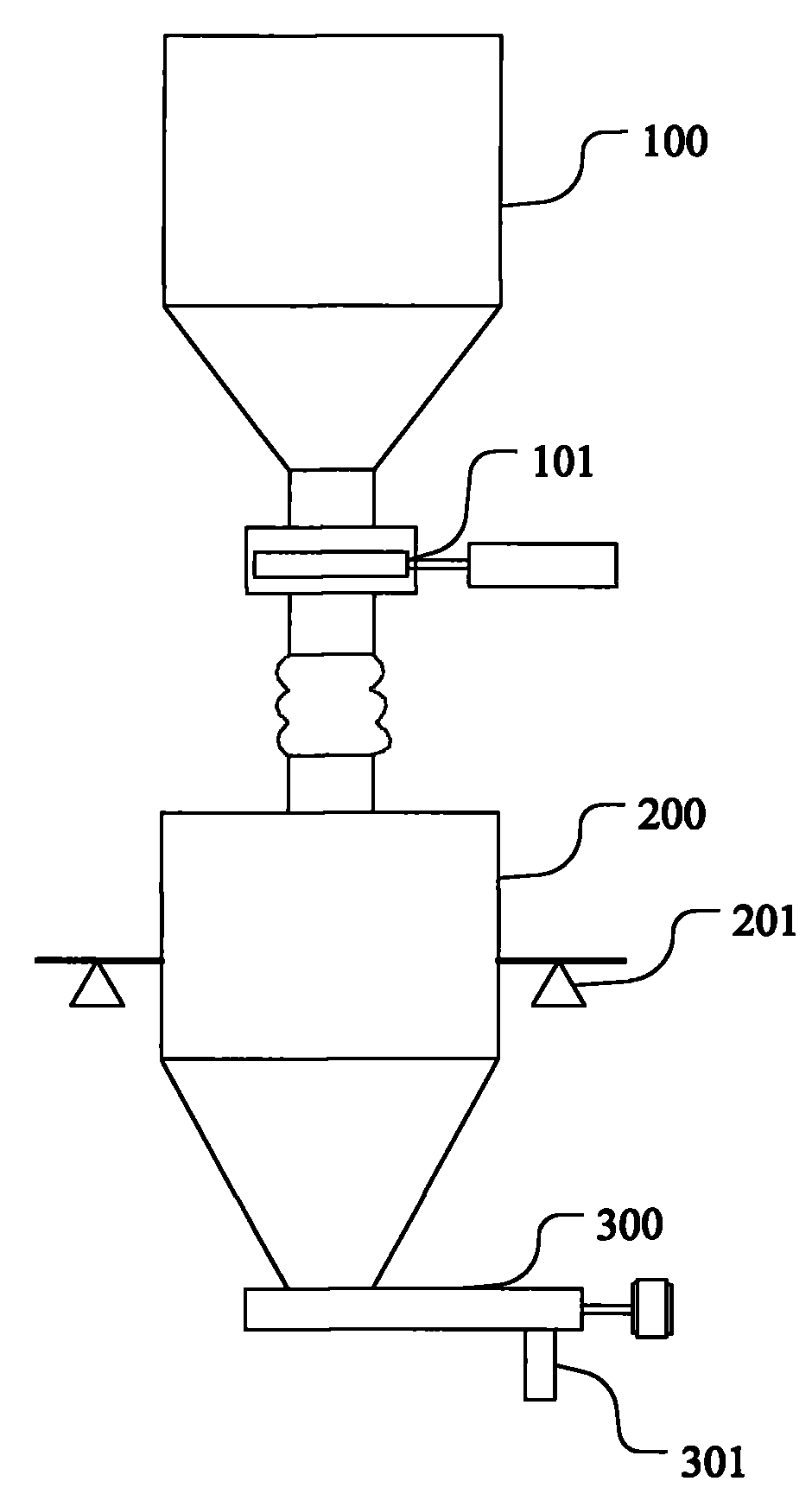

[0022] Such as figure 1 As shown, an intelligent dynamic loss-in-weight scale at least includes: a raw material bin 100, a weighing bin 200, and a feeding / dosing device 300, wherein a feeding valve 101 is arranged between the raw material bin 100 and the weighing bin 200, and the weighing bin 200 is provided with a weighing sensor 201 outside, and the feeder / batcher 300 is provided with a material outlet 301, and the material in the raw material bin 100 enters the weighing bin 200 through the feeding valve 101 and is fed by the feeder / batcher 300 The discharge port 301 outputs. When the weight of the material in the weighing bin 200 is lower than a preset lower limit, the feeding valve 101 is opened, and the raw material bin 100 is fed to the weighing bin 200; when the weight of the material in the weighing bin 200 is higher than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com