Connecting structure of evaporator and capillary tube

A connection structure and capillary technology, applied in the direction of fluid circulation arrangements, refrigeration components, refrigerators, etc., can solve problems such as capillary bending, inability to completely solve noise, complex processing technology, etc., to achieve small deformation, reduce probability, and reduce turbulence. flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical scheme of the present invention will be further described below in conjunction with the embodiment shown in the accompanying drawings:

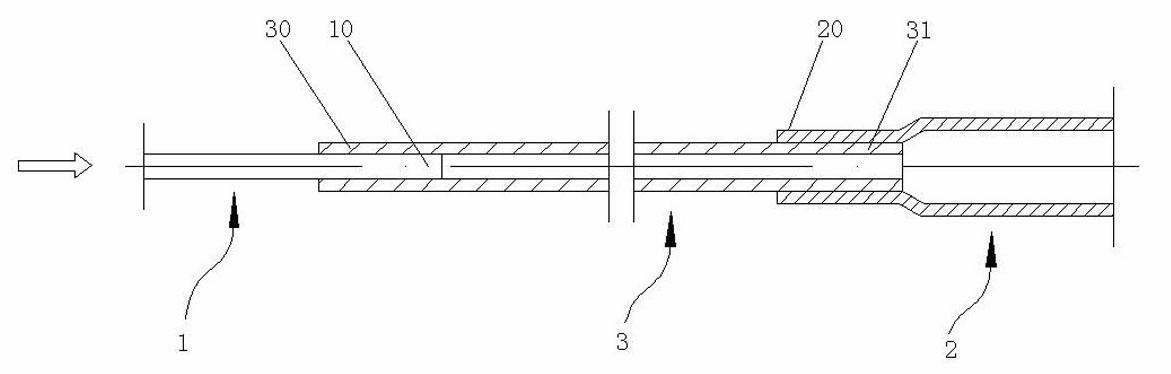

[0020] A connection structure between an evaporator and a capillary as shown in the figure, wherein: the capillary 1 has a liquid inlet and a liquid outlet 10, and the capillary 1 is made of pure copper (T2); the evaporator includes a liquid inlet 20 Evaporation tube 2.

[0021] Between the evaporating tube 2 and the capillary tube 1, a transition connecting pipe 3 is provided. The transition connecting pipe 3 is made of Bondi tube or pure copper (T2), and has a first connecting part 30 and a second connecting part 31. The transition connecting The tube inner diameter of the tube 3 at the first connecting part 30 is consistent with the tube outer diameter of the capillary tube 1 at the liquid outlet 30; the tube outer diameter of the transition connecting tube 3 at the second connecting part 31 is the same The inner diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com